Beijing PFM Screen Co., Ltd. products

Forming Fabrics

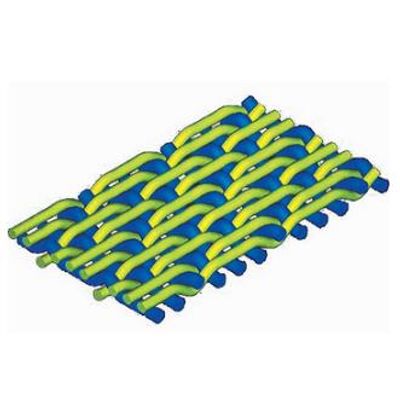

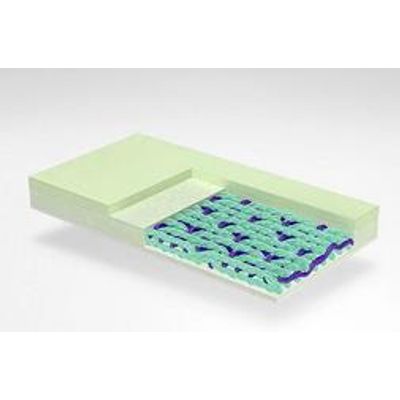

PFM - Paper Machine Clothing Single Layer Forming Fabric

The single-layer forming fabric is the simplest forming fabric. They are woven in 4-shed(Provides good stretch and drainage properties. Small fiber loss and good sheet release.), 5-shed(Provides better stretch and drainage properties than 4-shed. Retention can be improved by increasing weft yarns. Primarily used on tissue machines.), and 8-shed for different applications. In flat woven type fabric, the warp, during weaving, is composed of yarn which is referred to as MD yarn.

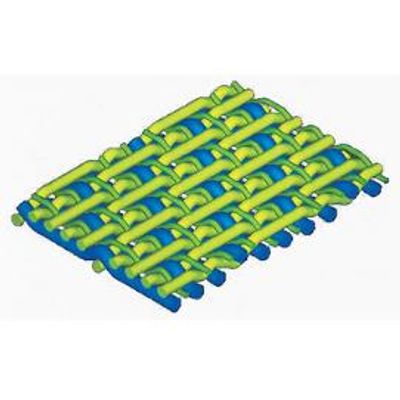

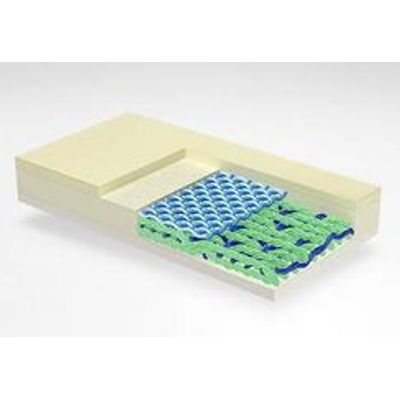

PFM - Paper Machine Clothing 1.5 Layer Forming Fabric

1.5 layer forming fabric is actually a 5-shed single layer fabric that has modified to have extra yarns which provide it the same properties as that of a double layer one. The extra yarns provide better sheet side smoothness as well as improved retention. Thanks to its unique structure, it delivers very good drainage and ease of cleaning. 1.5 Layer forming fabric is mainly used on the packing paper machine with machine speed 50m-400m/min, which have high air permeability as single layer forming fabric, and have a longer life than single layer forming fabric

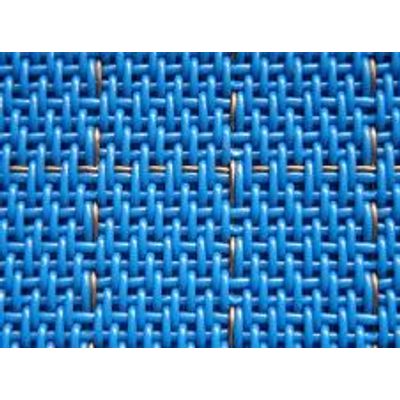

PFM - Paper Machine Clothing Woven Dryer Fabrics

PFM Screen can supply a wide range of woven dryer fabrics to ensure even and efficient drying of the paper web by promoting efficient and mass heat transfer. Woven polyester dryer fabric can be fabricated in single, double or two and a half layers to achieve different air permeability. It is also available in three-shed, four-shed or various other woven patterns based upon request.

Press Felts

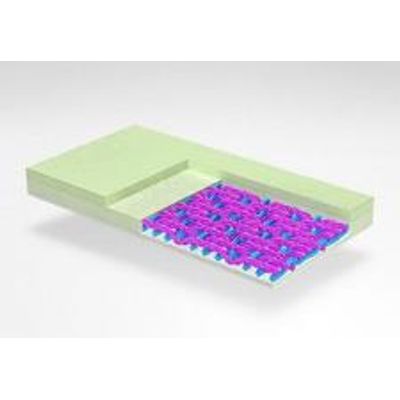

PFM - Paper Machine Clothing Single Layer Press Felts

Single Layer BOM Felt is made up of single base layer mesh fabric and fiber layer. The base layer is woven from synthetic mono-filament or multi-filament. The fiber layer consists of the various lap of fiber web and different diameters of fiber for better drainage and fiber support index. The structure is designed base on different paper machines, press types and different papers.

PFM - Paper Machine Clothing Double Layer Press Felts

Double Layer Press Felts include a 1+1 composite structure and a double layer of MD yarn structure. The 1+1 composite structure consists of two-layer base meshes of different thicknesses. Both of these base meshes can be changed in construction and sizes to suit the requirements of different paper machines. Double layer felts have the features of high press resistance, good flexibility, permeability and size stability, less elongation, excellent tensile strength. The felts are also resistant to vacuum marks, blind hole marks, groove marks, etc.

PFM - Paper Machine Clothing Triple Layer Press Felts

Three-layer BOM papermaking press felts include 1+2 composite, 2+1 composite and 1+1+1 composite three-layer BOM papermaking felts. The press felt can adapt to the linear pressure above 200kN/m, has the characteristics of good elasticity, good water filtering performance, can effectively eliminate all kinds of marks, stable size, long service life and so on. It is suitable for vacuum compound press of medium and high-speed paper machine, large wheel through blind hole press, shoe press and other types of press. Used for making all kinds of high-grade newsprint and cultural paper. Hanging panel paper. Jammed paper and other paper types.

Dryer Fabrics

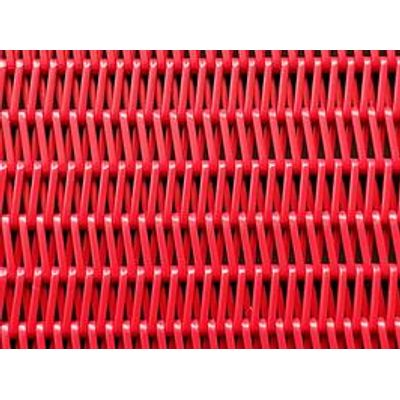

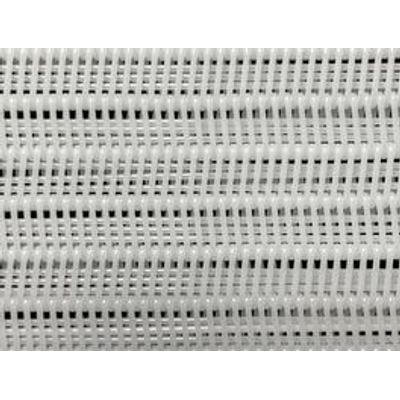

PFM - Paper Machine Clothing Spiral Dryer Fabrics

Spiral dryer fabric or screen is an endless construction comprising a plurality of spiral loops of monofilament yarns. The spiral loops linked by a pin yarn inserted in the adjacent holes. The specially designed spiral structure allows for rapid drainage, superb distortion resistance and eliminates the need for conventional seams compared with the woven polyester dryer fabric.

Filter Belts

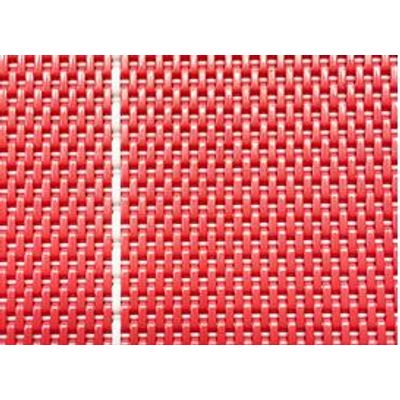

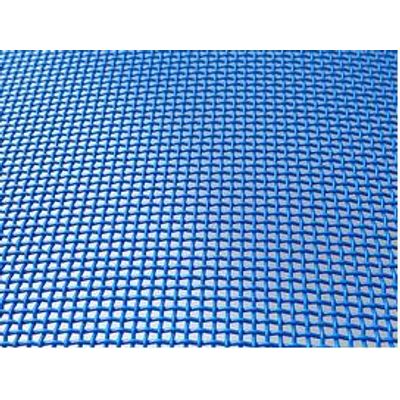

PFM - Polyester Linear Screen Mesh Conveyor Belt

Polyester plain weave mesh fabrics are also called linear screen cloth or polyester mesh conveyor belt. The weaving pattern is 2-shed and 3-shed available in various meshes, caliper, GSM and air permeability for different applications. They are widely used in various industries as dryer fabrics, conveyor belts, filter cloth and food & vegetables drying mesh belt.

PFM - Spiral Press Filter Belts for Belt Press Filter Cloth

Polyester Spiral Press Filter Belts are made with spiral dryer fabrics with extra filler yarns inserted in the spiral loops to reduce the air permeability and less material loss on the surface of the fabric. Polyester Spiral Press Filter Belt is also a monofilament polyester fabric but not like a woven fabric, instead this is a polyester fabric with spiral twisted wires where pins hold the spirals together like a chain. For years we have been manufacturing filter belts made of synthetic fabrics for a wide range of pressure belt filters of different sizes and designs, applicable for dewatering or solid-liquid separation in industries such as mining, chemical, food or wastewater treatment.

Special Belts

PFM - Antistatic Synthetic Mesh Belts

Under certain conditions of temperature and humidity, the equipment using a polyester mesh belt will produce high friction electrostatic when it runs at a high speed. Although the static current is usually of low intensity, it can be the cause of problems like when light pieces of product stay adhered to the surface of the belt which reduces the efficiency and product quality, or combustion risk in environments sensitive to deflagration.