- Home

- Companies

- Bellows Systems Inc

- Products

Bellows Systems Inc products

Metal Expansion Joints

Bellows Systems - Metal Expansion Joint

Bellows Systems can manufacture custom Metal Expansion Joints in many different configurations to suit your application. Bellows Systems manufactures using a wide range of materials for our metal expansion joints. The selection and use of various metals and alloys is based on the application, its physical properties and other properties like its resistance to corrosion and cyclic fatigue.

Bellows Systems - Single Expansion Joints

A Single Expansion Joint is an assembled product of various components like bellows, liners, flanges, tie rods, limit rods, collars. Single Expansion Joints come equipped with bellow elements and end connections like pipe ends, flanges, weld necks and other optional features such as collars, liners, and covers. The bellows will deflect in any direction or any plane depend on the pipe movement. It is a cost effective design option but requires that the piping be controlled to the direction of the movements of the bellows unit. The pipe expansion joint should not be expected to control the movement of the pipe. If the piping analysis shows that the pipe expansion joint must accept axial compression, then the piping must be guided and constrained so that only that movement will occur.

Universal Expansion Joint

Universal Expansion Joint for applications with primarily lateral movements.A Universal Expansion Joint contains two bellows with a connecting pipe or center spool between them. It is usually furnished with limit rods or full thrust tie rods, depending upon the service conditions. Tie rods or limit rods stabilize the center pipe connection and distribute movement evenly between bellows. Tie rods are required where it is necessary to absorb full pressure thrust and other externally applied loads.

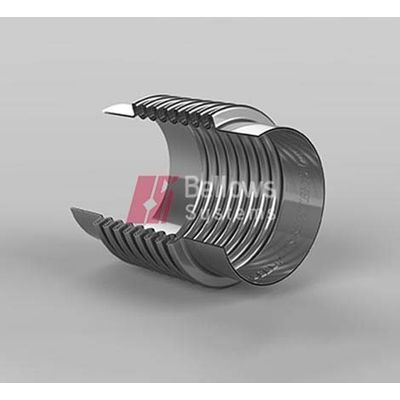

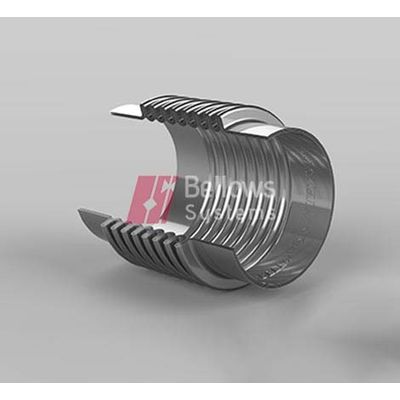

Metal Bellows

Single Ply Bellows

Single Ply Bellows are suitable for all applications that have relatively small movements. Single-ply Bellows are made up of a single tube (ply) of sheet metal of a defined thickness. They are typically suitable for applications having relatively small thermal movements and vibrations. Single-ply bellows are specifically designed for low pressure, high spring rate applications (150 PSIG at 1000 deg. F) where the single thin sheet metal is sufficient to withstand the design criteria. The fatigue cycle life of single-ply bellows is low in comparison to multi-ply bellows of similar overall ply thickness due to their higher spring rate. Bellows Systems single-ply bellows elements provide superior fatigue life and movement capability compared to flexible hose (flex-hose) connectors.

Two Ply Bellows

Two Ply Bellows provides good balance of bellows life spring rate & wider operating range. Two-ply Bellows are the most common type of Pipe bellows , providing a good balance of bellows life, spring rate and a wider operating range.Multi-ply Bellows are made up of two or more concentric tubes made of sheets of metal of a defined thickness. Bellows Systems Two-ply standard bellows designs (02 series Bellows) have been industry standard for over four decades. If you are unsure of what kind of Multi-ply bellows design is right for you, contact our engineers today and we will provide you with the right bellows for your application. All the Two-ply metal pipe bellows manufactured by Bellows Systems are in accordance with the Expansion Joint Manufacturers Association (EJMA) guidelines.

Multi Ply Bellows

Multi-Ply bellows are primarily used in high-pressure bellows applications where using a Single ply of material for a given pressure rating at a given temperature does not provide the spring rate low enough for the application. They usually tend to be a series of lower gauge plies which improves the cycle life, safety and flexibility compared to a similarly rated single ply bellows by reducing overall stress and decreasing the spring rate. These bellows are made up of N number of thin metal sheets of a specified design thickness. These bellows are particularly designed for the application of high temperature and high pressure conditions (>150PSIG @1000F). It can be extremely flexible in all directions, excellent vibration damper, very short compared to single ply with similar flexibility and have greater cycle life. Use of multi-ply bellows can dramatically reduce risk of leaks or failure of bellows due to metal fatigue.

Exhaust Bellows

Caterpillar Engines

Exhaust Bellows and Expansion Joints for Caterpillar Engines. Bellows Systems provides high-performance aftermarket Exhaust Bellows and Expansion Joints for medium to large Caterpillar Engines used in gas compression, marine propulsion, standby power, and other applications. Bellows Systems Exhaust Expansion Joints provides Multi-ply Bellows with superior cycle life for protection against fatigue failure. Avoid costly downtime by choosing Bellows Systems Exhaust Bellows.

Waukesha Engines

Exhaust Bellows and Expansion Joints for Waukesha Engines. Bellows Systems provides high performance aftermarket exhaust bellows and expansion joints for Waukesha Engines used in gas compression, power generation and other applications. Bellows Systems exhaust expansion joints provides Multi ply Bellows with superior cycle life for protection against fatigue failure. Avoid costly downtime by choosing Bellows Systems Exhaust Bellows for you Waukesha Engine Exhaust System.

White Superior Engines

Exhaust Bellows and Expansion Joints for White Superior Engines. Bellows Systems has been manufacturing and supplying quality OEM replacement Expansion Joints for Cooper and White Superior Engines since the early 70’s. Bellows Systems manufactures exhaust bellows for virtually every Superior engine model. Our standard designs include both Universal and Single type Expansion Joints.