Belt Tech Industrial products

Conveyor Belting

Belt-Tech - Heavy Duty Conveyor Belts

MAXX ARMOUR conveyor belts are specifically designed to perform in the most demanding bulk handling applications. Using STET DuPont™ Kevlar® AP in the carcass construction, these conveyor belts provide a belting solution for enhanced performance, and can be used on even the most critical conveyor systems.

Belt-Tech - Fire Resistant Conveyor Belts

AGNI is the Hindu noun for “fire.” By definition, thermal power plants utilize highly combustible materials as fuel. The possibility of ignition during the transport of these materials via conveyor belt is a constant threat. MAXX AGNI conveyor belts are specially formulated to resist ignition and to limit fire propagation in applications such as conveying coal over ground in thermal power plants. MAXX AGNI belts are available in varying formulations—flame resistant, low burning rate, low smoke and toxicity, heat and/or oil resistant, abrasion resistant, and more. Anti-static MAXX AGNI conveyor belts offer the most comprehensive range of fire resistant belts in the industry, reducing the risk of fire hazard and the potential loss to human life, materials, and installations.

Belt Tech - Conveyor Belts

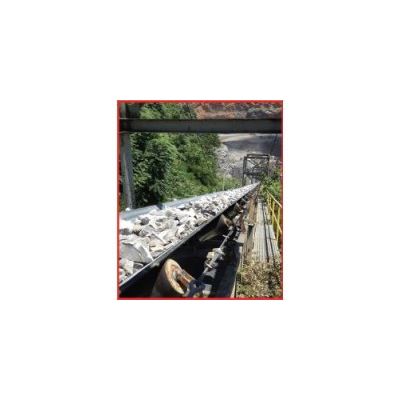

MAXX TUFF conveyor belts are ideal for surface and underground mining, aggregate and other industrial applications as the belt material is designed to resist cuts, gouging, and wear. MAXX TUFF belt cover materials are formulated with specific rubber grades that enhance and strengthen the properties required to transport such heavy-impact and sharp materials as crushed rock, limestone, coal, iron ore, sand, cement, wood chips, furnace slag, aggregate, and others.

Belt-Tech - High-Impact & Tear-Resistant Conveyor Belts

High-impact, high-tear conditions—such as the continuous pounding of rocks from primary crushers—can cause conventional multi-ply conveyor belts to fail due to carcass fatigue and shorten conveyor life. Unlike conventional multi-ply belts, MAXX ROCK conveyor belts are specifically engineered for high tenacity. The unique construction of the fabric ply and specifically-formulated cover compounds used in MAXX ROCK conveyor belts ensure higher longitudinal flexibility while guaranteeing very low elongation at working loads that standard EP/NN belts cannot handle. MAXX ROCK conveyor belts are made in single-ply or two-ply versions, offering strength ratings up to 1200 PIW.

Belt Tech - Fire-Resistant, Limited Propagation Belts

MAXX AGNI® conveyor belts are specially formulated to resist ignition and to limit fire propagation in applications such as conveying coal over ground in coal mines and in thermal power plants, and conveying coal in underground mines. MAXX AGNI® conveyor belts are also designed for conveying other materials which are prone to ignition during use. Fully compliant with MSHA Part 14 when correctly matched with the application, MAXX AGNI® belts are available in varying formulations—flame resistant, low burning rate, low smoke and toxicity, heat and/or oil resistant, abrasion resistant, and more. Anti-static MAXX AGNI® conveyor belts reduce the risk of fire hazard and the potential loss to human life, materials, and installations.

Conveying

TeleStacker - Conveyor

Overcome stockpile segregation. Portable or pit portable models. Production rates up to 5,000 TPH.

TeleStacker - Stacking Conveyors

TeleStacker Conveyor. Portable or fixed radial stacking. Stackable and track-mounted models.

Belt Tech - Portable Transfers

Pre-engineered or custom overland. Fixed or portable conveyors. Transport multiple conveyors per load.

Crushing

Liberty - Jaw Crusher

Superior® engineers and manufactures more than a dozen compression-style jaw crushers, useful in primary crushing applications like quarried stone, river gravel, recycled concrete and hard rock mining. An aggressively-shaped nip angle ensures the jaw dies consistently and dependably grip and crush rock. Liberty Jaw Crushers models range in capacity from 110 – 1,595 tons per hour (100 – 1,450 MTPH). Feed openings start at 20″ x 55″ (508×1,397mm) to 59″ x 78″ (1,500 x 2,000mm) with maximum feed sizes up to 47.2″ (1,200mm).

Patriot - Cone Crusher

Besides a strong commitment to service and convenient access to wear parts, the patented Patriot Cone Crusher is recognized for rugged structural integrity and high-grade components. Internally, bronze sleeve bearings are used for all load-bearing parts and critical components are cast of high-grade steel, exceeding existing standards. Superior® engineers uniquely designed high throw and high-pivot point crushing performance to achieve strong production rates at a low cost per ton. For protection from costly structural damage, each Patriot Cone Crusher is equipped with fail-safe hydraulics to defend the unit against damaging mechanical overload. Additionally, standard relief valves within the dual acting tramp relief cylinders provide immediate, alternative protection should the accumulator fail.