Bliss Industries, LLC products

Equipment - Hammermill

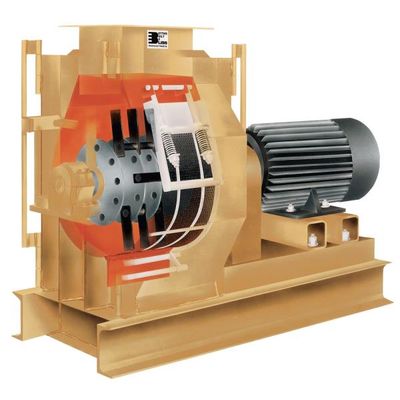

Bliss - Eliminator Hammermill

Increase your productivity and profits with a Bliss Eliminator Hammermill. Such features as internal wear plates, recessed reversible rotor, vortex cutter bar, one-piece plate housing, 3/8″ plate doors, octagonal shaped housing, double drilled rotors, and one-piece screen carriage maximize your grinding efficiency. Every Hammermill is individually sized based on research and decades of experience to fit your unique application and needs.

Bliss - Eliminator Relief Hammermill

The Bliss Eliminator “Relief” Hammermill is designed to efficiently grind high fat, oil, sticky, and difficult to flow products. Featuring the same heavy-duty construction and low maintenance design as the standard line of Eliminator Mills, the Relief Hammermill has been designed from the ground up to the handle even the toughest applications. The Bliss Eliminator “Relief” Hammermill will provide your operation the competitive edge necessary to maintain maximum profitability. Give us the opportunity to show you the features that make Bliss the choice of competitive professionals.

Bliss - Model EMF - Eliminator Hammermill

The Eliminator Fine Grind Hammermill is designed to fill the gap in granulations between a traditional hammermill and an air swept pulverizer or fine grinder. The granulation range of the EMF mill is in the 40 – 100 mesh range depending on the product and application.

Equipment

Bliss - Model OP›‹FLO - Air Stream Cooling System

The OP›‹FLO Cooler has been refined to utilize an upward moving stream of ambient air to cool the product. As the air rises through the product, the product is cooled while the air is warmed. The warmer air meets the product entering from the top minimizing the temperature shock it is exposed to and preserving the highest quality. The product exiting at the bottom of the cooler is cooled to near ambient air temperature. The gradual heat transfer greatly enhances the product quality, reduces stressing, and fines. Through the falling product, hence the opposite flow or OP›‹FLO.

Bliss - Crumblers

The Bliss Crumbler is made for easy installation under OP›‹FLO Cooler and is built with a low profile design. Its rolls are held in place using compressed air to eliminate the “bouncing spring effect.”

Bliss - Pellet Mills

Developed from a design concept proven worldwide since its introduction in 1975, the range of Pioneer Pellet Mills continues to expand. Designed with max efficiency overall durability, ease of operation, and maintenance. As core principles, Bliss Pellet Mills provide lower operating costs to each owner. With a wide range of die sizes, die speeds, and drive power, Bliss can design a system to meet your requirements with both quality and cost-effectiveness.