Boselan Tanks Co., Ltd (BSL) products

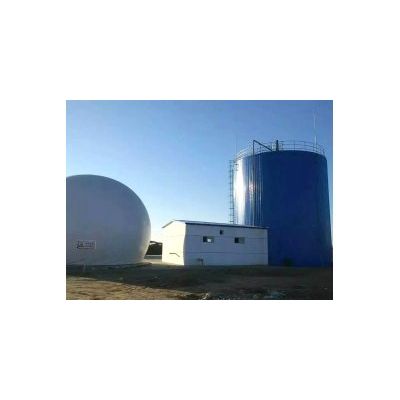

Anaerobic Digestion Tank

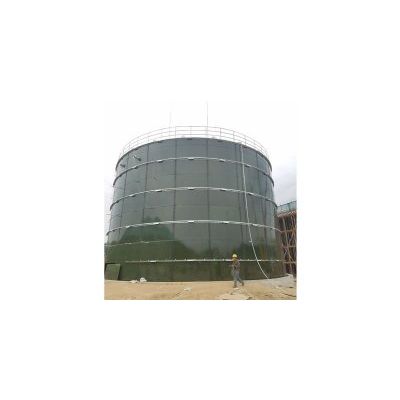

Model GFS - Glass-Fused-to-Steel Bolted Tank

(Glass-Lined-Steel, Enamel Bolted) is a unique tank finish. Two materials are fused together to achieve the best properties of both – the strength and flexibility of steel combined with the corrosion resistance of glass. Glass Fused To Steel Tanks are the leader of Storage Solutions industries, which is widely used as Water Storage Tanks for Potable Distribution Line, Bio Gas Plant, Waste Water Treat Plant (WWTP) etc. With the advantage of both GLASS and STEEL, Glass Fused To Steel Tanks can resist corrosion of Waste Water of PH 1 - 14. Applied to double layers, Glass-Fused-to-Steel is able to provide more than 30 years of trouble free service in harsh environments. This system has been proven over many decades on thousands of installations, and is supported by International Standards which cover the design and finish requirements:

Bolted Steel Tank

Wastewater Storage Tanks

Short construction period. Superior corrosion resistance, service life is more than 30 yeas. Low project cost. Tank volume can be easily expanded. Beautiful appearance, color can be customized. Not subject to weather conditions. No need big installation equipment. Easily expand, dismantle, movable.

Glass Fused to Steel Bolted Tank

Concrete Tanks

Easy Construction: All the tank shells of Glass-Fused-To-Steel Tanks are factory coated, can be easily assembled and installed in difficult conditions, to meet the urgency requirement of project, unlike Concrete Tanks will be affected seriously by bad weather and other factors. Corrosion Resistance: Concrete tank would corroded through to reinforcing bar within 5 years of installation, Glass-Fused-To-Steel Tanks with 2 layer of Glass coating, can be applied for PH from 3 to 11, Center Enamel also provide 2 Years Warranty of its Glass-Fused-To-Steel Tanks. Leakage and Maintenance: Concrete is susceptible to cracking so that many Concrete Tanks show signs of visible leaks and require substantial remedial maintenance, Glass-Fused-To-Steel Tanks are an excellent alternative with less maintenance due to the steel strong tension strength.

Fire Water Tank

We are the manufacturer, each a piece of steel plate can be customized, welcome customers to visit our factory, the size of the nozzle, and operating direction, can be customized. Because its core is titanium alloy steel plate, and China is the biggest producer, so no matter from price advantage and quality, our company is your best choice.

GFS Tank - Waste Water Treatment

Municipal Sewage Treatment Tank

The treatment of municipal sewage requires a large amount of waste water, which is increasing every year. The glass fused to steel tank is flexible and can adapt to the increasing amount of municipal sewage.And our company has a professional team, according to the design of good specifications, we can provide supporting equipment.At the same time, we can change the size and specification of the tank according to the needs and design requirements (within the safe range of international standards) to meet the needs of municipal sewage treatment.

Aeration Tank

The aeration tank uses the activated sludge process for sewage treatment. The tank provides a certain amount of time for the sewage to stay, so as to meet the oxygen required by aerobic microorganisms and the mixing conditions for the sewage to fully contact with the activated sludge.The smooth enamel surface of the GFS tank can prevent the growth of other substances and prevent other substances from affecting the water purification rate.The most important point, the maintenance and care cost of the latter period is relatively low, at the same time, the construction cost is lower than the cement tank, the appearance can be customized, no matter from which aspect is your best choice.

Clarifier Tank

Clarifier tank, clarifier tank is the application of precipitation removal of suspended matter in the water of a structure, water purification equipment.Remove suspended matter from the water by natural precipitation or coagulation precipitation.The clarifier tank is divided into horizontal clarifier tank and vertical clarifier tank according to the direction of water flow.The GFS tank can well meet this demand, and the installation cost is higher than the cement tank bottom, and the transportation cost is higher than the fiberglass tank bottom, which is the hot product in the sewage plant construction and the first choice of many customers.

Waste Treatment Tank

Because of the flexibility and convenience of GFS tank, it can be used in any link of sewage treatment, aeration tank, sedimentation tank, chlorine tank, etc. Because of its splicing property, it greatly improves the diversity of sewage treatment design. According to different positions and different periods, it can flexibly connect the operation between various tanks, plus the anti-corrosion performance of GFS tank, it is now the first choice of sewage treatment equipment.