Branch Environmental Corporations products

Branch - Scrubbing Packed Towers Used for Gas Absorption

Packed Towers are used for gas absorption including acid gases such as S02, HCl and others. Packed Towers can also absorb solvents such as Alcohol and gases such as Ammonia. Almost any water soluble chemical can be removed from the gas using a Packed Tower. Packed Towers can also be used to remove trace quantities such as removing odors including Hydrogen Sulfide. This type of scrubber can also be used for cooling gas, aeration and any other application where transferring from a gas to a liquid is required.

Branch - Model HE - Venturi Scrubbers

Venturi scrubbers are used to remove very small particles; mist and can also remove gases. The open design eliminates opportunities for the solids buildup and minimizes maintenance. Particles down to and including submicron sizes can be captured. Venturi scrubbers can also absorb gases such as Sulfur Dioxide or others that react with neutralizing chemicals. The scrubber can handle high temperature gases and variable gas rates by use of an adjustable throat design.

Branch - Jet Venturi Scrubbers

Jet Venturi scrubbers can remove dust and gas simultaneously. Their advantage is the ability to handle high concentrations of gases such as Chlorine or other water soluble gases. In many applications, the Jet Venturi can be used without any additional fan. Jet Venturi scrubbers use the energy from the liquid sprayed into the Venturi to create a pull on the gas drawing it into the scrubber. The gas and liquid are then mixed in both the spray section and in the high velocity Venturi throat.

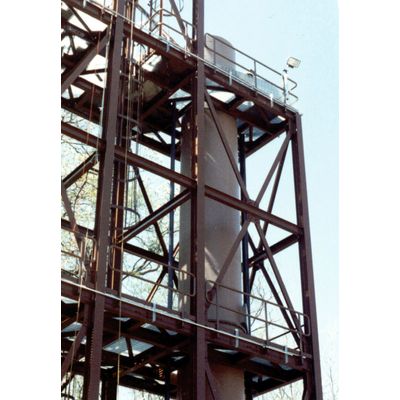

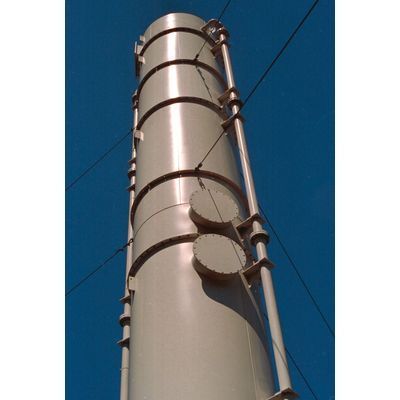

Branch - Air Strippers for Water Purification System

Branch provides custom built Air Stripper units for removal of voc, ammonia, hydrogen sulfide and other volatile components from water. With our experience in complete systems, we can provide you with all of the related components and controls for a trouble free installation.

Branch - Ammonia Removal Strippers

Where ammonia is present in water to be treated, you can remove it using air stripping technology. By a combination of pH adjustment and temperature, we calculate the tower size for any required efficiency. The most common application is for waste water at ambient temperature. By increasing the pH to 11, removals in the 80-90% range can be provided. With large systems, the discharge air will need treatment to collect the ammonia. We provide a closed loop system where the discharge air is treated with an acid wash to form a salt from the ammonia and the air is reused in the stripper.

Branch - Hydrogen Sulfide (H2S) Strippers

Removal of Carbon Dioxide from water can be accomplished at low cost using a Branch Air Stripper. The C02 Degasifier is simply an air stripper designed specifically for removal of dissolved carbon dioxide. Ambient air can be used to remove the dissolved gas down to low levels. The quantity of air needed to do this is small. Hydrogen Sulfide (H2S) can be removed from water using air stripping technology. Most common applications in water treatment use a simple air stripper. The difference is that the pH is adjusted to 4 – 5 which will convert the soluble sulfide ion completely to a dissolved gas as hydrogen sulfide. The gas then is volatile enough that by blowing air counterflow to the water, the hydrogen sulfide will be removed from the water phase.

Branch - Steam Stripping System

Steam stripping systems are available for removal of organics such as Benzene as well as dissolved gases such as Ammonia. Steam stripping involves the same type of technologies used in our Air Strippers. Because of the higher operating pressures normally used, the random tower packing is replaced with trays. The tray designs are especially helpful in some refinery applications where accumulation of tars or other materials can occur and the trays are much easier to clean. While the pressure drop is significantly higher, it is negligible compared to operating at a pressure of 15 – 30 psig (1 – 2 Bar g) for example.

Branch - Catalytic Oxidation System

As the amount of organics in the air decrease, you have to add more supplemental heat. One way to minimize this is to use a Catalyst. Catalysts reduce the temperature required for combustion. For example the operating temperature for a catalytic unit may be in the 600°F / 300°C range. This would reduce the operating cost compared to Direct Thermal Oxidation if the VOC is very low in concentration. Branch can help you evaluate the best choice.

Branch - Direct Thermal Oxidation

Direct Thermal Oxidation involves simply applying heat to the contaminated air until the temperature is raised enough for combustion to occur. Organic compounds have a temperature at which they will begin to oxidize even if no direct flame were present. For example, if a organic compound has an auto ignition temperature of 932°F / 500°C, it would begin to convert to carbon dioxide and water, assuming enough oxygen is present. In practice, a higher temperature is needed to assure that you get good destruction efficiency. The actual temperature could be up to double the auto ignition temperature depending on the desired removal.

Branch - Regenerative Thermal Oxidation System

In a Regenerative Oxidizer, an effort is made to get the absolutely highest possible energy recovery. This type of design is aimed at low concentrations of organics. Since you can recover a very high percentage of the energy, you can operate with low fuel use. This has to be balanced against any cases where you might actually encounter much higher levels of inlet VOC which could overheat the oxidizer.