- Home

- Companies

- Brawn Mixer

- Products

Brawn Mixer products

Mixers

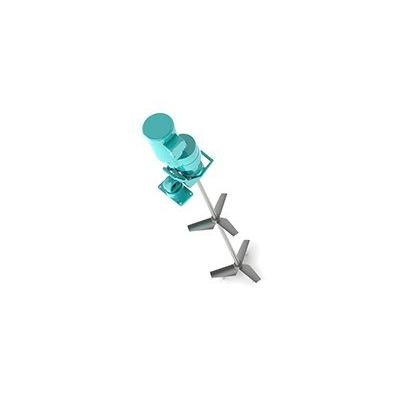

Brawn Mixer - Model B Series - Portable Mixers

Brawn Mixer B Series mixers are the backbone for some of the most demanding applications in the processing industries. Our engineered-to-application approach, built on the Brawn Mixer modular platform and backed by the toughest quality standards, ensures long-lasting performance. The flexibility of the B Series platform makes it well suited for larger batch/continuous mixing applications in a variety of industries, including chemical, food and beverage, pharmaceutical and life sciences, and health and beauty processing, as well as in water/wastewater treatment. B Series mixers are available with stainless steel or high strength aluminum housings and oversized driveshaft and bearings to increase performance and mixer life. Flexible output couplings also protect against excessive torque and absorb shock loads.

Model BD Series - Mixers

These mixers provide unique features to benefit customers with Extremely long life and serviceability. The modular construction gives users high quality, rugged components in a design that allows interchangeability between direct-drive, gear-drive, fixed-mount or portable-mount mixers. These mixers also offer a high capacity double drive bearing, providing a unique blend of load carrying capacity and smooth, quiet operation.

Model BDSS Series - Stainless & Sanitary Premium Direct Mixer

Brawn`s premium direct mixer leads the product series with design features that provide superior performance and long service life. This mixer is equipped with an all stainless steel motor and drive components. Popular process applications include pharmaceuticals, food processing, cosmetics, chemicals and challenging environments where corrosive vapors destroy other mixers. Motors are TENV or TEFC and are wash-down duty. Mixers in this series range from 1/2 to 5 HP, with voltages of 115/230 - single phase or 230/460 - e phase. These BRAWN extra tough Stainless & Sanitary mixers stand up to aggressive chemicals or meet your sanitary mixing requirements in addition to utilizing Brawn`s renowned, Mix & Match concept for parts interchangeability and unparalleled versatility.

Model BGM Series - Mixers

The BGM Series offers a compact, high capacity, helical gear reduction. The drive shaft is independently supported with two sealed, permanently lubricated bearings. NEMA C-Face motors from 1/2 to 4 HP are standard. Other motor options include DC with variable speed control, explosion-proof or air. Best of all, the BGM utilizes the same modular design, with all metal housings, as the BD Series. This means lower total cost for a mixer of superior quality and features.

Model BGMF Series - Mixers

Sealed tank applications are no problem for Brawn`s BDF and BGMF models. In fact, Brawn utilizes the modular design concept here as well, in order to maximize the options while minimizing the cost. Once you identify your process requirements, allow Brawn Mixer to show you the best and most cost effective way to achieve the required solution. A wide variety of stuffing box and mechanical seal options are pre-engineered for quick delivery.

Model BGSS Series - Stainless & Sanitary Mixer

The premium partner to the Brawn BDSS is the BGSS which exhibits the same superior performance characteristics, but with a high capacity, helical gear reducer. Optional gear ratios are available in addition to the standard 5:1. In addition to the standard TENV or TEFC motors from 1/3 to 5 HP, variable speed control is also available . A variety of stuffing box and mechanical seal options are pre-engineered to reduce delivery time. These BRAWN extra tough Stainless & Sanitary mixers stand up to aggressive chemicals or meet your sanitary mixing requirements.

Model BTO Series - Mixers

One of the work horses of the Brawn line, the BTO mixer is all helical gear reduction, providing both high torque and high efficiency. It is available in open or sealed tank versions. Motor options include NEMA and metric standards - one (1) HP through 10 HP. The BTO can be angle mounted to eliminate the need for tank baffles.

Model BWG Series - Mixers

The BWG offers versatility in horsepower range and output speeds in compact,right angle mixer drive. It is also available with optional drywwell construction, with a wide range of mounting configurations. One of its greatest features is the high gear ratio for low speed applications, such as flocculation or polymer blending.

Model LD/SD Series - Mixers

The LD/SD Series includes both single-phase and three-phase 1/3 HP motor options. Air powered and variable speed models are available. They are designed to mix water like fluids in volumes up to 200 gallons or up to 75 gallons of 250 centiposie. These high speed mixers provide a combination of high shear with good flow for low volume applications. The LD can be supplied with a drum adapter and folding impeller for entry through a 2` drum bung. The SD can be provided with a sanitary mount.

Model LG / SG Series - Gear Drive Mixers

The LG / SG Series are gear drive mixers designed for mixing water like fluids up to 500 gallons or up to 50 gallons of a 2000 centipoise material. Available in either single or three-phase AC electric or with air motors or DC variable speed motors. Fixed speed models operate at a speed of 430 RPM. The SG adds the benefit of an oversize drive bearing, which provides for longer shaft lengths in deeper tanks.