- Home

- Companies

- Brofind Spa

- Services

Brofind Spa services

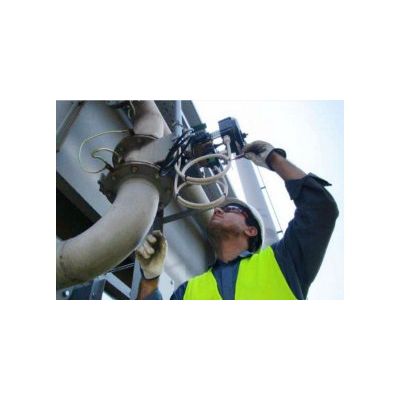

Support / Services

Our internal division SERVICE specializes in personal assistance services: from the remote control of the system operating state to the activities maintenance ordinary and extraordinary. Among our services also we signal the sieving active carbon and catalysts, respectively for solvent recovery and catalytic oxidizers, to maintain the efficiency of the installations in time .

Thermal Oxidation Installation Services

The thermal oxidation allows the transformation of pollutants into secondary products with a reduced environmental impact through the completion of the following reaction: COV + O2 = CO2 + Energy Activation + H2O + heat. The reaction must take place under suitable temperature conditions, turbulence and residence time in a combustion chamber; the energy required for the activation of the reaction and the heat developed can be recovered by means of suitable heat recovery systems (recuperative thermal oxidation).

Regenerative Thermal Oxidation Installation Services

In the regenerative thermal oxidation plants the heat recovery takes place by using ceramic materials able to accumulate and lose heat quickly , depending on the direction of crossing of the gases that pass through them. We propose solutions to 2 rooms, 2 rooms with compensation, 3 bedrooms, 5 rooms or more depending on the efficiency of abatement demand and the flow of air to be treated .

Catalytic Oxidation Services

The oxidation of the pollutants takes place using a catalyst, which greatly reduces the activation energy required for the completion of the reaction. The plant can be equipped with a conventional heat recovery section (recuperative catalytic oxidation) or regenerative type (with the use of ceramic materials), optimizing in this way the energy consumption.

Solvent Recovery Services

The recovery of the solvents is carried out through the transfer (adsorption) of the pollutant content of the gas in the issue to an adsorbent material (usually activated carbon) which then is removed through the use of a hot fluid (steam or nitrogen, depending on the solubility in water pollutant). The plants are equipped with auxiliary systems for: the treatment of condensate; the reduction of the steam consumption (economizer); dehydration and distillation of the recovered solvent.

Concentration Installation Services

The concentration of the pollutants plant allows to obtain reduced flow of air with high concentrations of pollutant from originally high flow rates with reduced concentrations of pollutant; Once concentrated, the output is sent to a final purification treatment. The concentration of the pollutant is through adsorption on suitable materials (zeolites or activated carbon) which in turn are regenerated with a hot gas, which constitutes the concentrated emission. In this way it is possible to reduce considerably the dimensions and the operating costs of the plant for final treatment or further decrease the emission values of existing plants.

Wet Treatment Services

Wet treatment allows the removal of the pollutants contained in atmospheric emissions by absorbing them in a liquid. This will only happen at suitable contact conditions. It is often necessary to dose reactors in order to make these conditions more favorable to convert pollutants into more transferable products.