- Home

- Companies

- Buckau-Wolf GmbH

- Products

Buckau-Wolf GmbH products

Sugar Technology

Buckau-Wolf - Vacuum Pans with Honeycomb Calandrias

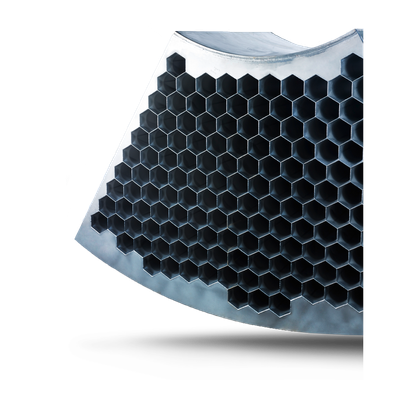

Buckau-Wolf Vacuum Pans equipped with honeycomb calandrias are engineered to enhance industrial crystallisation processes by reducing boiling time and energy consumption. These patented calandrias feature a unique design where pipes are arranged in a honeycomb pattern, optimizing the heating surface and facilitating efficient heat transfer. The system includes a central circulation pipe and a stirrer that ensures thorough mixing and directed flow, resulting in improved crystal structure and reduced processing time. Designed in compliance with the European Pressure Vessel Directive, these devices are versatile, supporting retrofitting to upgrade existing systems with minimal modification. They integrate easily into operation, making them a preferred choice in sugar factories worldwide, offering efficient heat exchange and homogeneous material suspension. Additionally, Buckau-Wolf provides comprehensive engineering and inspection-related services, including CAD drawings, welding instructions, and documentation in multiple languages, ensuring adherence to technical standards and operational safety.

Buckau-Wolf - Discontinuous Centrifugals for Sugar and Chemical Industries

Buckau-Wolf discontinuous centrifugals are used in the production of white sugar and raw sugar massecuite in the sugar industry, dextrose, mannite, xylite, isomalt and fructose massecuite, sugar substitutes, suspensions of similar consistency in the chemical and food industries

Buckau-Wolf - Distribution and Fill-Up Tanks for Crystallization

Buckau-Wolf distribution tanks are specifically engineered to meet the unique requirements of the crystallization process in sugar manufacturing. Drawing on extensive experience, these tanks are designed to handle massecuite post-crystallization, ensuring its movement and further sugar crystal growth during the cooling phase. The integral role of these tanks is to maintain constant motion and even distribution of massecuite to the centrifugals, acting as a crucial intermediate step between fill-up tanks and centrifugals. Constructed with stainless steel for all contact parts, they emphasize durability and hygiene. The incorporation of low-maintenance seals effectively prevents leakage, while a standard gear motor powers the system, enhancing reliability. Custom-designed to align with customer-specific applications, these tanks exemplify Buckau-Wolf's commitment to technical excellence in sugar technology.