- Home

- Companies

- Buffalo Wire Works

- Products

Buffalo Wire Works products

Self Cleaning Screens - PFX- HT

Buffalo - Self Cleaning Screen

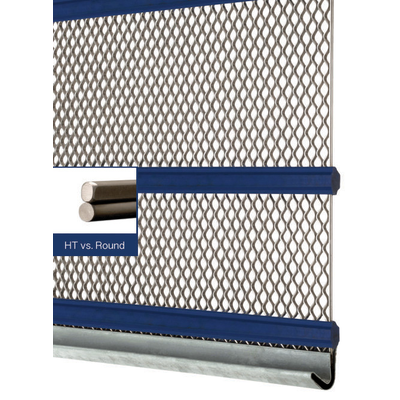

The Clean PFX HT - M2 Series (Patent #8893894) is ideal for the exact sizing of passing material in extreme scalping, near-size, and heavy load conditions while increasing overall screening efficiency and throughput. All wires are independent of one another and form effective square openings. This series produces a high-quality, consistent product and is highly effective in harsh conditions. It often replaces plate, welded wire, and synthetics where blinding and throughout are paramount issues and critical parameters.

Buffalo - Self Cleaning Screen

Clean PFX HT – M Series (Patent #8893894) utilizes profile wire technology cast in pure urethane strips. M HT is ideal for the exact sizing of passing material in heavy loading conditions while increasing screening efficiency and open area per unit time. M HT utilizes an equivalent spherical wire or a larger mass of wire, obtaining significantly longer screen life and similar open area. All wires are independent of one another and form effective square openings. The M HT series produces a high-quality, consistent product and is highly effective in most non-blinding to mild blinding conditions.

Self Cleaning Screens - PFX - Round Wire

Buffalo - Round Wire Self Cleaning Screen

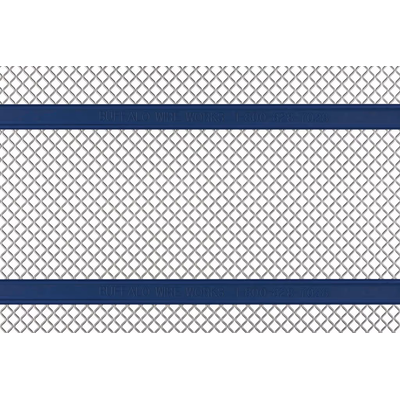

The Clean PFX -M Series is ideal for the exact sizing of passing material while increasing screening efficiency. All wires are independent of one another and form effective square openings. The M series produces a high-quality, consistent product and is highly effective in most general applications.

Buffalo - Round Wire Self Cleaning Screen

The Clean PFX - M2 Series is ideal for the exact sizing of passing material in moderate scalping, near size, and heavy load conditions while increasing screening efficiency. All wires are independent of one another and form effective square openings. The M2 series produces a high-quality, consistent product and is highly effective under challenging applications. M2 often replaces plate, welded wire, and synthetics where blinding and throughput are paramount and critical parameters.

Self Cleaning Screens - PFX - Modular

Buffalo - Modular Tensioned Self Cleaning Screen

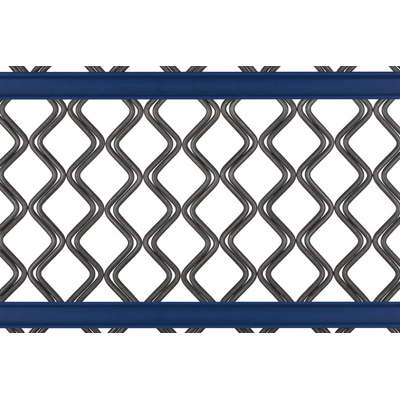

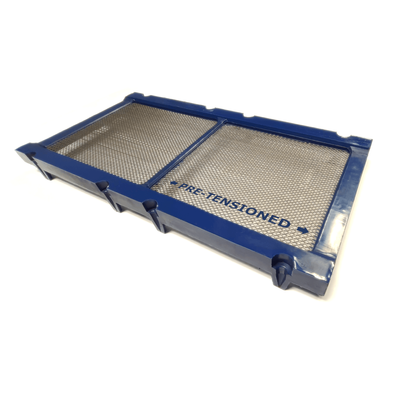

Revolutionary Technology to Solve Age-Old Problems. The unique high tensioning of the screening media insert prevents pocketing and performs as efficiently as a hooked screen.

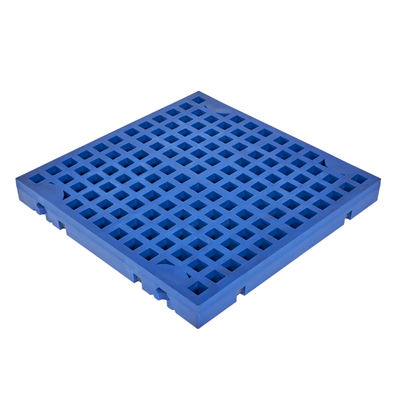

Urethane Products - OEM Compatible Modular Screen Panels

Buffalo - Compatible Modular Screen Panel

The pin-less panel easily snaps into place. Available in standard and maximum open-area design. Only a mallet is needed for installation. 1’ x 1’ panel. Available in 30, 40, 45 and 50mm thicknesses. Available in 4 and 6 fastening points. Available in small and large snap sizes.

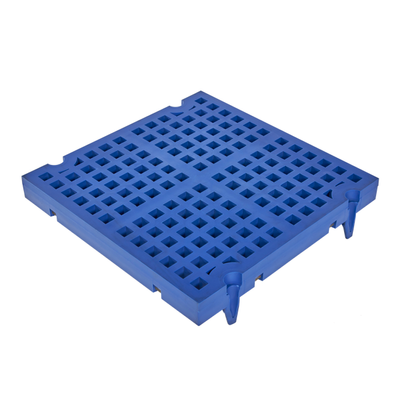

Buffalo - Pin & Leg Compatible Modular Screen Panel

Available in standard and maximum open area design. 1’ x 1’ and 1’ x 2’ panels available. Available in 30, 40, 45, 50, 60, 80 and 100mm thicknesses. Available in 4, 6, 8,12,16 and 18 fastening points.

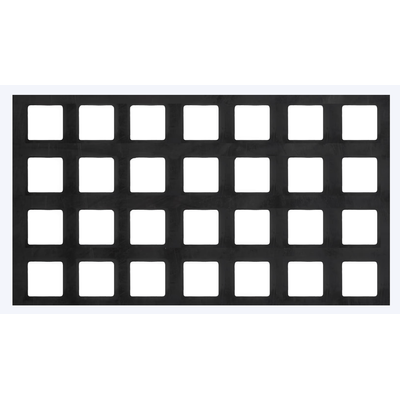

Buffalo - Pin & Sleeve Compatible Modular Screen Panel

Rubber Products - Rubber-Backed Plate

Buffalo - Bolted Rubber-Backed Plate

Commonly used on Deister machines, these panels are available in standard 4` x 4` bolted-in configurations and are also compatible as replacements for Polydeck Armadex style panels. They can be manufactured with or without skid bars to meet the demands of heavier-duty applications. For added protection and extended wear life, bolts are typically shielded with rubber plugs that fill the counterbore.

Buffalo - Hooked Rubber-Backed Plate

These panels are available to fit any side tension or split-deck hooked screen machines. Each design is engineered to blank out support bars, maximizing open area and enhancing screening efficiency while extending screen life. Tapered openings help reduce blinding, ensuring consistent performance. Options include full rubber-backed plates and plate-framed panel styles to deliver increased screening action and durability.