BW Filling & Closing products

Capping Machines

Pneumatic Scale - Mechanical Rotary Capping Machine

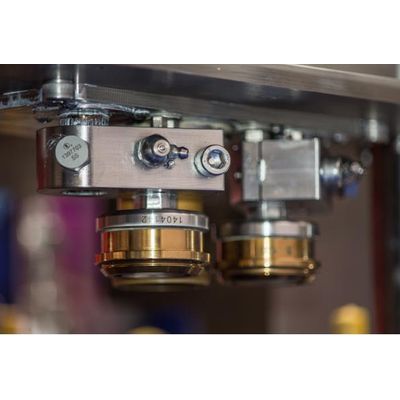

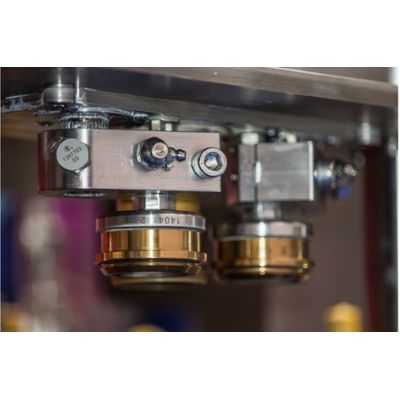

The PC Mechanical Rotary Capping Machine by Pneumatic Scale is crafted for precise and versatile applications in pump capping scenarios, catering to different cap types including screw caps, press-on caps, and plugs. Featuring magnetic torque control, it ensures accurate torque application with minimal slippage. The machine accommodates a wide range of container materials like glass, metal, plastic, and fiberboard, with a speed capacity of between 30 to 240 containers per minute, depending on model specifics. This machine incorporates an all-mechanical, sanitary stainless steel design and offers fast changeovers with the Zepf MARK II® Change Part System, enhancing operational efficiency. It features innovative measures like anti-rotation mechanisms for secure handling and a mechanical stem guide system ensuring precise pump orientation, coupled with motorized turret height adjustment for quick adaptations in production settings, ensuring streamlined performance.

Pneumatic Scale - Servo Rotary Capper

The SPC Servo Rotary Capper from Pneumatic Scale is engineered for precision sealing across a range of container types including glass, metal, plastic, and fiberboard. This machine employs servo motors to achieve precise torque control critical for creating a proper seal. The Servo Cam technology maintains consistent torque across various container sizes and types, offering production flexibility. Customizable turret pockets manage non-round containers, while round containers benefit from a gripper belt or clamp table to prevent slipping, scuffing, or crushing. The machine integrates cap timing with its turret for reliable cap pickup, thus avoiding misalignment even at high speeds. With its in-process torque control, feedback, and diagnostic capabilities, the SPC capper ensures torque accuracy better than ±1 inch-lb. for varying ranges. Features include a user-friendly touchscreen interface, real-time monitoring for application torque verification, and quick tool-free changeovers with the Zepf MARK II® system. The capper is available in standalone or monoblock configurations and is suitable for hazardous environments. It can include automated reject/inspection systems with optional auto lubrication and is capable of handling speeds from 12 to 400 CPM based on model and specifications.

Pneumatic Scale - Mechanical Rotary Capper

The Pneumatic Scale's TC Mechanical Rotary Capper is engineered to deliver reliable capping solutions for a wide array of container types, spanning materials such as glass, metal, plastic, and fiberboard. This state-of-the-art machine features customized turret pockets that ensure secure handling of non-round containers, while a gripper belt or clamp table option offers additional stability for round containers. With magnetic torque units providing precise mechanical torque control, and cap transfer arms or disks ensuring consistent alignment, the TC capper excels in preventing common issues like spilling, slippage, and scuffing. Designed for high-speed operations, with flexibility in managing various cap types, this capper supports efficient changeovers and maintenance-free performance. The user-friendly interface further enhances control, making the system adept at handling up to 600 containers per minute with precision.Pneumatic Scale - Servo Rotary Capper

Pneumatic Scale`s SC capper is ideal for practically any container. Servo motors ensure accurate torque control, which is critical to producing a proper seal. Customized turret pockets control non-round containers, while a gripper belt can be added to hold round containers. Because the machine holds each container securely until capped, spilling, slipping, scuffing and crushing are eliminated.

Craft Beverage Canning Lines - Inline Volumetric

Pneumatic - Open Air Integrated Canning Line

The CB Series of integrated filler/seamers provide canning technology designed specifically for and scaled to the needs of craft beverage packaging. Open air or atmospheric filling is cost-effective for still and lower-carbonation products, and is relatively simple to operate and maintain.

Pneumatic - Counter-Pressure Integrated Canning Line

The CB Series of integrated filler/seamers provide canning technology designed specifically for and scaled to the needs of craft beverage packaging. Counter-pressure or isobarometric filling can require more knowledge of filling technology and packaging, as well as a slightly higher investment than open-air filling. However, it allows for greater flexibility in product range, including hard seltzers, sparkling wines and higher carbonated beers. Counter-pressure filling handles beverages from still to high carbonation products (up to 4.1 Vols of CO2), and is the preferred method for high production environments. Counter-pressure filling also offers precise control over production variables by filling into a purged, sealed container, using easily-adjustable machine parameters (e.g. purge length, purge cycles, etc.) and is less impacted by temperature variations. CO2 loss and DO pickup are minimized.

Pneumatic - Open Air Integrated Canning Line

The CB Series of integrated filler/seamers provide canning technology designed specifically for and scaled to the needs of craft beverage packaging. Open air or atmospheric filling is cost-effective for still and lower-carbonation products, and is relatively simple to operate and maintain.

Craft Beverage Canning Lines - Rotary Volumetric

Pneumatic - Rotary Counter-Pressure Canning Line

The CBR family of craft beverage canning lines brings rotary counter-pressure filling together with rotary Angelus seaming in a compact footprint, operating at speeds up to 250 CPM. Currently available as a 12/3 (12-head filler, 3-spindle seamer), 16/4 (16-head filler, 4-spindle seamer), or 24/4 (24-head filler, 4-spindle seamer) configuration, the CBR full rotary design enables faster speeds and a smooth, continuous motion transition from filling to seaming, eliminating unnecessary agitation, and reducing Dissolved Oxygen (DO) levels.