BW Industries Limited products

Mezzanine Flooring Systems

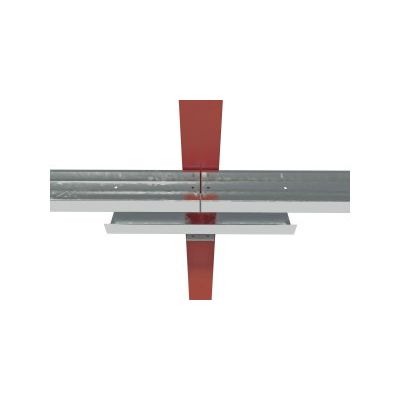

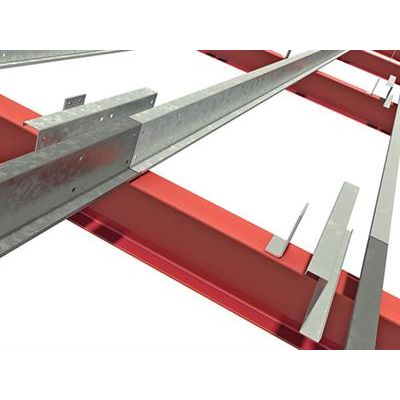

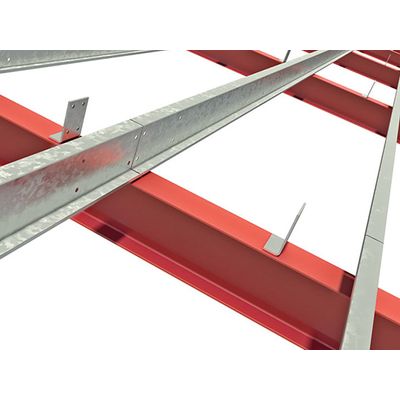

BW Industries - Primary Mezzanine Floor Beams

BW Industries supply a wide range of galvanised Cee sections. The larger section sizes are ideal for use as primary beams in place of fabricated hot rolled beams. Optimum section selection ensures an efficient floor design, resulting in cost savings. Primary beams can be designed using the BW Building Wizard Software.

BW Side Rails

BW Industries - Side Rail Sections and Sleeves

Designed in accordance with BS EN 1993-1-3. Manufactured by cold roll forming of pre-hot dipped galvanized strip to BS EN 10346 with minimum tensile strength of 450 N/mm2 and Z275 coating. Section ranges are referenced “Z” followed by three digits being the overall depth in mm. Individual sections are referenced “Z” followed by five digits the first three being the overall depth in mm and the final two being the gross material thickness in mm multiplied by 10. Sleeve references - replace `Z` with `SL`. Use the BW Building Wizard Software for accurate calculations. All holes are 14mm diameter unless stated otherwise. Other diameters are available on request.

BW Industries - Butt Jointed Rail System

The butted side rail system is suitable for all building types but is primarily used in single span applications. It is the simplest side rail system and can be used in inset and oversail configurations. Non-standard end configurations can be accommodated as required.

BW Roof Purlins

Eaves - Beam Cleat & Stiffening Bracket

The eaves beam cleat is used for the main stanchion connection to the eaves beam section. The eaves beam stiffening brackets are bolted inside the eaves beam to offer a fixing point for the eaves tie fixing bracket.

BW Eaves - Tie with End Brackets

The BW eaves tie with end brackets connects the eaves beam to the bottom purlin. Comprising: 45 x 45 x 2mm galvanised angle with end brackets factory-fitted to preset angle. Eaves beam and bottom purlin punched at 14mm diameter to accept eaves ties.

Heavy End Bay System

The heavy end bay system is a variation of the sleeved system which is suitable for buildings with five or more bays. Heavier gauge sections are fitted to the end bays with corresponding heavy gauge sleeves to all penultimate rafter connections. Inner bay purlins are of lighter gauge as are the inner bay sleeves which are fitted at every connection. The system can be used with double span inner bay purlins with fewer inner sleeves.

Steel Framing Systems

BW Industries SureBUILD - Framing Systems

BW Industries have installed a SureBUILD Framing rolling mill, housed in by a purpose built factory, to produce a range of steel framing that can be supplied in either stick form or fully assembled panels. The assembled panels are fitted together using a sophisticated Rivet System, which is both time and cost effective.

Roof Purlins - Roof Purlins

BW Industries - Roof Purlins Sections and Sleeves

All holes are 14mm diameter unless stated otherwise. All holes are punched in pairs on standard gauge lines. Detail sheets for BW’s standard range of Cee Purlins (C Purlins) and Sleeves are available in PDF format from the Downloads section.

Roof Purlins - Purlin Systems

BW Industries - Butt System

The butted purlin system is suitable for all building types but is primarily used in single span applications. It is the simplest purlin system and can be used in inset and oversail configurations. Non standard end configurations can be accommodated as required.

Roof Purlins - Roof Variations

BW Industries - Monopitch Roof

For monopitch and other roofs where there is no restraint to the ridge purlin via apex ties some equivalent anchor must be used. This may take the form of a simple tie to a substantial ridge beam or alternatively by a combination of struts and diagonal bracing between the top two purlins. Restraints should be used at mid-span for purlin spans greater than 3.5m and at one third and two thirds of span for purlin spans greater than 7.5m. For long roof slopes additional diagonal bracing may be required.