C. Cramer & Co. GmbH products

Composite Materials

Cramer - High Performance Spread Tow Fabrics

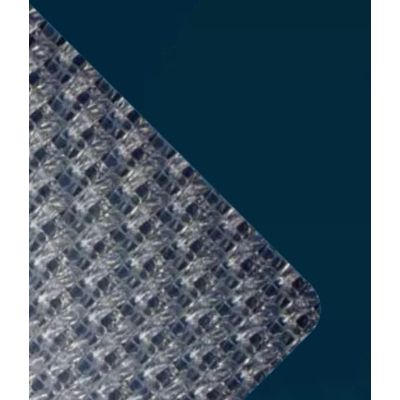

The eSpread High Performance Spread Tow Fabrics are an innovative product designed by C. Cramer & Co. GmbH, aimed at revolutionizing the production of lightweight reinforcement structures. These fabrics are recognized for exceptional surface coverage and performance, employing a novel approach by replacing lower count filament fibers with higher count ones, while maintaining low weight, such as 200 g/m² with 12K carbon fiber as opposed to 3K fiber. Structurally, these fabrics offer reduced thickness and crimp, resulting in a higher fiber volume fraction which minimizes resin requirement. Their design facilitates superior mechanical performance through improved fiber alignment and decreased gaps. The fabrics also present a more homogeneous warp and weft distribution, enhancing surface aesthetics. Moreover, the level of closure imparts stiffness, reducing the need for post processing work. These technical advancements make eSpread fabrics a significant innovation in composite material applications.

Cramer - Unidirectional Carbon Fiber Fabrics

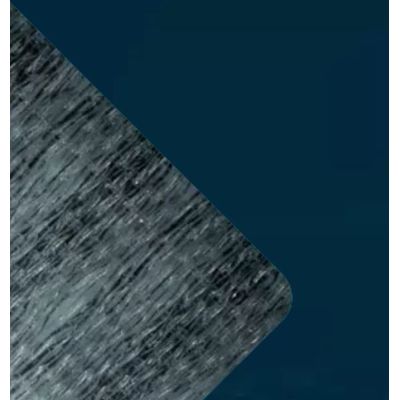

Unidirectional carbon fiber fabrics (UDs) by C. Cramer & Co. are designed with all fibers aligned in a single direction, optimizing their strength and stiffness along the intended load path. This design reduces material waste and allows for customization of mechanical properties, enhancing overall performance while maintaining a lightweight profile. The uniform and low-profile design of these fabrics facilitates seamless integration into complex shapes, making them ideal for aerospace, automotive, and sports equipment industries. UDs offer superior surface coverage and quality, ensuring uniform reinforcement and minimal imperfections, which are crucial for structural integrity. The absence of crimping ensures fibers remain parallel without distortion, enhancing tensile strength and stiffness. The high strength-to-weight ratio of UDs makes them suitable for applications requiring lightweight yet durable materials. Additionally, their aerospace prepreg level ensures they meet strict quality standards for aerospace-grade materials, providing consistent mechanical properties and structural reliability.

Filtration Fabrics

Cramer - Woven Wet Filtration Fabrics

C. Cramer & Co. specializes in the manufacturing and finishing of woven wet filtration fabrics, which are essential in the separation of solids from liquids across various industrial settings. These fabrics are engineered to purify water, wastewater, and other liquid mixtures by trapping solid particles while permitting the liquid to flow through. Available in woven constructions, these filtration fabrics are crafted from both synthetic and natural fibers and are tailored to meet specific requirements in terms of pore size, durability, and chemical resistance. The fabrics are prominently used in crucial sectors such as chemical manufacturing, food and beverage production, mining, and water treatment. C. Cramer & Co.'s long-standing expertise in filter fabric production makes them a preferred partner worldwide for industries seeking innovative and reliable filtration solutions.

Cramer - Double Layer Fabrics for Process Filtration Applications

Double layer fabrics are engineered materials optimized for enhancing filtration efficiency and durability across diverse industrial processes. These fabrics integrate two layers with distinct functions: the top layer is finer and primarily captures smaller particles while offering a smooth surface for the efficient release of filter cakes; the bottom layer provides coarser mechanical strength, supporting the delicate top layer to ensure structural integrity during continuous filtration. This composition enhances particle retention, boosts flow rates, and minimizes clogging, resulting in extended service life, reduced maintenance expenses, and increased process reliability. These fabrics are applicable in various industries like water treatment, chemical processing, food and beverage production, and pharmaceutical manufacturing, where precise separation of solids from liquids is vital. The flexibility of double layer fabrics for different filtration mechanisms, such as pressure or vacuum filtration, and compatibility with various types of filtration equipment make them an adaptable and efficient solution for process filtration challenges.