Carlson Engineering & Manufacturing products

Fixtured Drive Heads - Type 1

Carlson Engineering - MiniMod Type 1 Drive Head - Dual-stage Automatic Screwdriver Head

The MiniMod Type 1 Drive Head by Carlson Engineering is a versatile dual-stage automatic screwdriver head designed to enhance industrial screwdriving automation. Engineered for streamlined assembly processes, it integrates seamlessly into various setups requiring precision in screw advancement and tightening. The system breaks from traditional constraints with dual independently operating travel slides, allowing enhanced reach in complex applications. Equipped with a robust 9-nm torque capacity, it supports diverse screw types including bolts, pins, and rivets. Its lightweight design, approximately 1.8 kilograms excluding the screwdriver tool, facilitates integration into low payload robotic arms. The drive head's adaptability makes it compatible with most commercially available screwdrivers, complemented by a quick-change bit system and linear guide bearings for durability. The device incorporates advanced features such as optional depth control, screw presence detection, and non-contact jaws for enhanced operational efficiency.

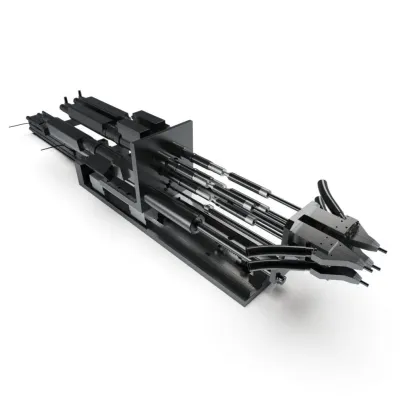

Carlson - MultiDrive Multi-Spindle Automatic Drive Head

The MultiDrive Multi-Spindle Automatic Drive Head is an advanced tool designed for industrial automation in screwdriving applications. It features a configuration capable of driving multiple screws or fasteners simultaneously or individually depending on application requirements. The drive head supports up to 18 screwdriving spindles, each programmable to suit specific tasks, making it a highly versatile component in assembly automation. Its robust design includes a torque capacity exceeding 200 Nm and a weight of over 75 lbs, ensuring its capability to handle heavy-duty tasks. Engineered to integrate seamlessly with blow-feed automatic screwfeeders, it is also adaptable for driving various fasteners such as bolts, pins, and rivets. The MultiDrive's construction incorporates a quick bit change system, linear guide bearings for extended operational life, and options for depth control and screw presence. Additionally, it offers compatibility with a wide range of screwdriver brands available in the market, making it a flexible solution for diverse industrial applications.

Handheld Drive Heads

Carlson SuperDrive - Handheld Automatic Drive Head

The SuperDrive Handheld Automatic Drive Head is a sophisticated tool developed for industrial screwdriving automation. This device offers a streamlined approach to automated screw assembly, designed to integrate seamlessly with screwfeeders or step feeders. The SuperDrive is engineered to manage high torque applications without transmitting reaction torque to the operator's wrist, enhancing ergonomic comfort. Featuring a 25-nm torque capacity, it is lightweight at 4.5 kg before attaching a screwdriver tool, and offers easy bit changes. It includes features such as linear guide bearings for durability, limit switches for precision control, and a bracket for screw presence detection. Adaptable to most screwdrivers, it can also be utilized for driving various fastener types like bolts and rivets. Additionally, the system supports CoBot integration, allowing for optimized collaborative robotic applications in modern manufacturing environments.

Carlson SureDrive - Handheld Automatic Drive Head

The SureDrive Handheld Automatic Drive Head by Carlson Engineering is a versatile and efficient solution for industrial screwdriving automation. This device is engineered to work in harmony with automatic screwfeeders, enabling a streamlined approach to assembly automation. Its lightweight and ergonomic design enhances operability, making it suitable for various screwdriver tools and stands available on the market. Key features include a 20-nm torque capacity, quick screwdriver bit change capabilities, and linear guide bearings that ensure long life and low maintenance. It also supports extras like depth control and screw presence detection. Designed to integrate with a range of screws, bolts, and more, the SureDrive head offers flexible application compatibility. Additionally, when paired with a DC Electric tool, it supports process verification through a Poka-yoke mechanism. Its adaptability, combined with a thoughtful design, ensures it meets diverse industrial needs efficiently.

Screw Feeders

Carlson - Vibratory Bowl Screw Presenter With Hopper

The A24 Vibratory Bowl Screw Presenter With Hopper is a meticulously engineered automation solution for manufacturing applications requiring reliable screw presenting. Featuring a substantial 24-inch vibratory bowl, this system efficiently aligns and presents screws for pick-up without the need for air pressure. The bowls are custom-tooled to precise fastener specifications, enhancing longevity and compatibility. Its design incorporates advanced alignment verification steps, including a sorting air jet, qualifying track cover, and an optic sensor to prevent jams and ensure continuous operation. The system's track level sensor eliminates the need for positional adjustments. Built for easy maintenance, the escapement parts can be precisely reassembled post-cleaning, ensuring operational consistency. Its robust construction, along with its low-maintenance approach, provides a durable platform for manufacturers seeking improved efficiency in automated screw feeder operations.