- Home

- Companies

- Case Group

- Products

Case Group products

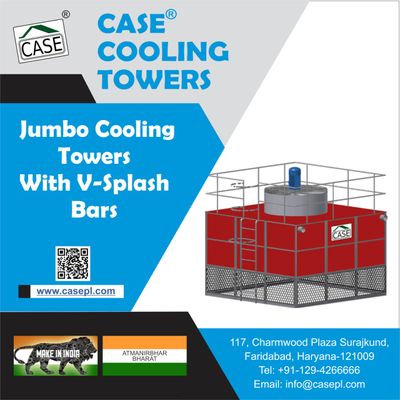

Case - Model RT Series - Cooling Towers

This RT series consists of cooling towers, which are square / rectangular in shape. The series is specially designed for high water flow rates because of its multi cell feature. A number of cells can be clubbed together forming multi cell cooling tower thus giving the end user performance and efficiency. This cooling device also come in completely knocked down condition and are erected at site. These cooling towers replace conventional biodegradable wooden cooling tower and ensure no Legionnaires` disease and algae problems.

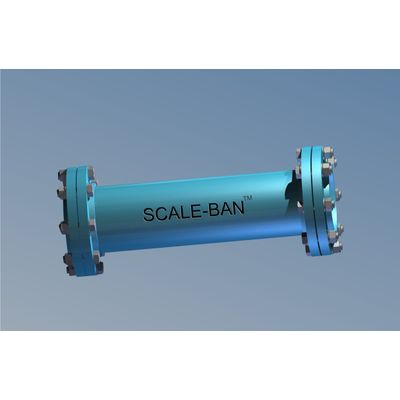

Case Scale-Ban - Non-Chemical Water Treatment System

SCALE-BANTM is an innovative concept in the field of hard water scale problems. It comes in the shape of a pipe and can be easily installed in the present cooling water circuit. This On-line equipment does not require any energy for operation. It requires no regeneration or maintenance, resulting in Zero equipment down time and zero equipment deterioration. The theory of working of SCALE-BAN TM is very simple. It makes the use of flow and chemical characteristics of water and precipitates out hardness causing salts of very small size as the water flows through SCALE-BAN. Theses salts are suspended in water because of being very light in weight and the turbulent flow of water. Thus, once the precipitation causing salts are precipitated and suspended in water, further precipitation because of temperature variation is not possible. The result is a totally scale free system.

Casepl - Turnkey Air Pollution Dedusting System

CASE provides turnkey Air pollution solution for all types of industries. The selection of Air Pollution Control Equipments and the design are tailor made for a particular industry. Air pollution is the residual of industrialization. The unwanted byproduct ingredients when pumped into the atmosphere, contaminate the natural air, hence causing air pollution. These pollutants are harmful to the living and the non-living. Air pollution can cause serious health problems. Increased levels of concentration can result in severe injury and even death. Air pollution has thinned the protective ozone layer above the Earth resulting in susceptibility to the living kind against innumerable diseases and disorders. CASE realizes the unimaginable effects of this biggest nuisance faced by the Human Civilization today. We have dedicated our efforts to minimize or eliminate this problem by supplying the industry with various Air Pollution Control Equipment.

Case - Direct Reduced Iron (DRI) Tunnel Kiln

FINES TO SPONGE DRI (Direct Reduced Iron) Tunnel Kiln was commissioned on 24 November 2011. CASE gave this technology to India and this was also first of its kind in India. The process has been established now after earlier hiccups. The process of Tunnel Kiln uses fines of Iron ore and Coal which are mixed together in specified proportions to eventually make DRI having quality grades of 90% plus metallization.

Case - Model CNC Lathe Series - Roll Turning

Roll Turning CNC Lathe series are mainly used for turning not only the end face, ex-circle surface, but also the conical surfaces of various work-pieces. This machine adopts three supporting structure with good rigidity. It is known for designing flexible lateral chip removal system with good performance and accuracy. This machine is equipped with separate oil pump for excellent lubrication. The tailstock movement adopts mechanical device with reasonable rotation speed, feed rate and power. This kind of lathe is respected worldwide for its high rigidity, efficiency, energy-saving, easy of operation and attractive appearance.

Case - Multi Stand High Speed Block Mills

Block Mills are becoming increasing popular in India. Initially, block mills were setup by steel producers whose main product was wire rod. The trend is rapidly changing for TMT bars too. Today steel producers who are wanting to increase their production capacities opt for Block Mills as their finishing mill group.