Cellwood Machinery AB products

Dispersers

Model HDS - Hot Dispersing System

As the most advanced system the HDS produces the best dispersing results. It is also the most flexible system, with optional features such as in-line bleaching. The key feature of hot dispersing is treatment with high temperature at high pulp consistency. This leads to many advantages: improvement of fiber properties, reduction of bacteria, and softening of dirt and tacky contaminants for a more efficient dispersing. Retention time is 2 minutes at a temperature of up to 120°C (248°F). The system is further described below – with all the treatment steps for dewatering, heating, dispersing and bleaching.

Model CDS - Compact Dispersing System

The CDS is the only non-pressurized system. This principle allows for a more compact design: a conveyor can be used to replace both the plug screw and the shredder, and there is no need for pressure vessels or sealings for HC discharge. The non-pressurized concept gives a low steam consumption, and the design also allows for existing dewatering equipment to be used. Retention time is 20-30 seconds at a temperature of up to 95°C (203°F). The system is further described below – with treatment steps for dewatering, heating and dispersing.

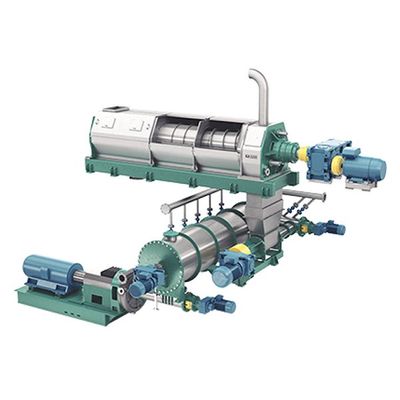

Model UCD - Ultra Compact Dispersing System

The UCD system consists of only three machines: screw press, infeeder/steamheater, and disperser. This solution offers the most compact design possible, something that saves both plant space and investment cost. Retention time is 5–10 seconds at a temperature of up to 110°C (230°F). The system is further described below – with treatment steps for dewatering, heating and dispersing.

Pulpers

Horizontal Pulpers

The horizontal pulper design allows for a lower build height as well as a lower energy consumption. It can be customized with any of the rotor units described below.

Vertical Pulpers

The G-rotor is used for pulp with low dry content, for example in UTM positions such as couch- and press pulpers.

Microfilters

ALGAS - Microfilter

The Algas microfilter can be described as a drum filter with special features. Filtering from the inside and out allows the recovery trough to be installed on the inside of the drum. This means the filter operates with a much higher level compared to conventional designs, increasing filtration time and improving efficiency.

Bioenergy

Model GRS - Reject Separator

The reject separator is used for removal of plastics and metals from pre-treated substrate. The substrate is pumped through a Ø6 mm screen where the reject is separated from the organic material.

High Density Cleaner

The high density cleaner is used for removal of grit from biogas substrate. Incoming organic waste includes particles from sand and glass which remain as contaminants in the processed substrate. The high density cleaner uses the vortex principle to continuously remove those particles.