- Home

- Companies

- CeramTec GmbH

- Products

CeramTec GmbH products

Hermetically Sealed Piezo-Ceramic Actuators

Piezo-ceramic multilayer actuators must be effectively protected against moisture to ensure reliable and lasting operation. Conventional polymer or ceramic coatings can only offer this to a certain degree. Tests have shown that leakage current greater than 1 mA already occurs here within a few seconds. CeramTec has an answer to this problem: Hermetically sealed actuators with active moisture suppression. No other company in the world offers this solution.

Electromechanical Transducer

Piezo-ceramics are used to convert mechanical parameters, such as pressure and acceleration, into electrical parameters or, conversely, to convert electrical signals into mechanical movement or vibration. Piezo-ceramic materials are categorized as functional ceramics. In sensors they make it possible to convert forces, pressures and accelerations into electrical signals, and in sonic and ultrasonic transducers and actuators they convert electric voltages into vibrations or deformations. Piezo-ceramic materials are classified according to their chemical composition on the one hand, and by the specific application conditions on the other.Oxide Ceramics

CeramTec - Electromechanical Transducer

Piezo-ceramics are used to convert mechanical parameters, such as pressure and acceleration, into electrical parameters or, conversely, to convert electrical signals into mechanical movement or vibration. Piezo-ceramic materials are categorized as functional ceramics. In sensors they make it possible to convert forces, pressures and accelerations into electrical signals, and in sonic and ultrasonic transducers and actuators they convert electric voltages into vibrations or deformations. Piezo-ceramic materials are classified according to their chemical composition on the one hand, and by the specific application conditions on the other.

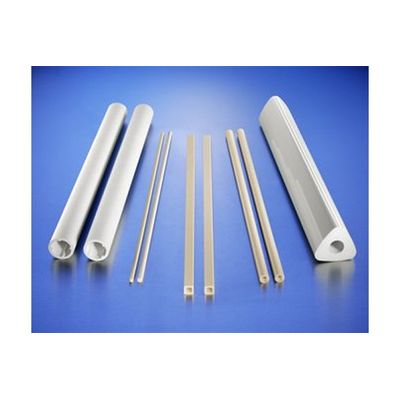

CeramTec - Ceramic Pipes and Tubes

CeramTec produces a variety of ceramic pipes and tubes in myriad shapes, materials and manufacturing processes, even for specialized or custom applications.

CeramTec - Advanced Ceramic Tubes and Insulators

Advanced Ceramic Tubes and Insulators for Thermocouples, RTD’s and special Applications in Temperature Measurement. Protection and insulating tubes made from technical ceramics are the first choice in temperature and measurement control situations, whenever safety and stability aspects are required.

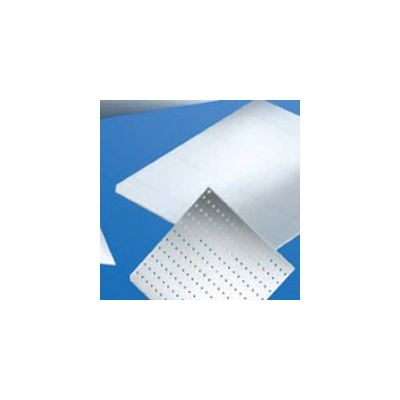

Substrates

Rubalit - Alumina Ceramics

This ceramic material is characterized by its extremely high strength and thermal conductivity. The outstanding surface quality on both sides makes it the perfect companion for any commercial thick film paste and even makes it suitable for a number of thin film applications (sputtering).

Alunit - Aluminum Nitride Ceramics

Achieving maximum performance in the smallest possible space inevitably causes electronic components to develop increasingly high temperatures. This heat must be dissipated quickly and reliably in order to protect the valuable components. This is where CeramTec Alunit® aluminum nitride ceramics set the benchmark.

Other Products

Hermetically Sealed Piezo-ceramic Actuators

Piezo-ceramic multilayer actuators must be effectively protected against moisture to ensure reliable and lasting operation. Conventional polymer or ceramic coatings can only offer this to a certain degree. Tests have shown that leakage current greater than 1 mA already occurs here within a few seconds. CeramTec has an answer to this problem: Hermetically sealed actuators with active moisture suppression. No other company in the world offers this solution.

CeramTec - Piezo-Ceramic Transducers

Power conversion composite transducers, also referred to as Langevin-Bolt transducers (LBT), are made from specially developed piezo-ceramics characterized by low dielectric loss and high mechanical Q-factors. CeramTec offers the material types SONOX® P4 and SONOX® P8 with different property profiles. SONOX® P4 is suitable for ultrasonic cleaning and non-destructive testing transducers. Its high coupling factors, medium-range Q-factors, and excellent mechanical stability permit high oscillation amplitudes at resonance. The achievable active power output in transducer configurations (emitting unilaterally in water) varies between approximately 7 and 10 W/cm2. The maximum operating temperature of the ceramic is 125°C. Its compressive strength depends on the mounting conditions (homogeneous load distribution) with 70 maximum MPa in continuous mode.