- Home

- Companies

- CH Four Biogas Inc.

- Services

CH Four Biogas Inc. services

Consultation Services

CH Four experts regularly provide consultation services to a variety of audiences on the economic, environmental, and societal benefits of anaerobic digestion facilities.Feasibility Study Service

Feasibility Studies are a first step in determining both the technical and economic viability of your project. CH Four Biogas has extensive experience with assessing these aspects of anaerobic digestion projects in the agricultural, municipal and industrial sectors and a variety of jurisdictions.

Construction Management Service

CH Four Biogas provides construction support, design-build services, and turnkey projects. In addition, we are available to support you during construction whether or not we provide the design drawings for the project.

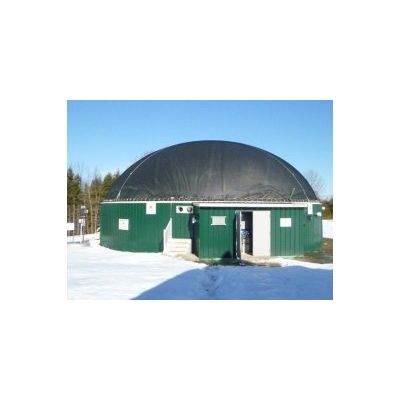

Operational Support Service

Servicing a biogas system sometimes translates into downtime. Minimizing unplanned instances is key. Our experts know what threatens the reliable performance of a digester system. Thus, from inception, our systems are designed with a view toward long-term sustainability and operational efficiencies.

De-Packaging System Design & Integrated Services

In addition to offering turn-key biogas facility design services Yield offers a System Integration Service whereby waste management companies or operating AD plants can install custom contaminant removal equipment to fit their requirements to accept and processes contaminated feedstock.

Feedstocks Evaluation and Digestion Process Modeling Services

CH Four Biogas has developed a computer simulation program that replicates the effects of various feedstocks on the anaerobic digestion process. This simulation tool allows us to model biogas system performance, optimize performance of existing biogas plants, and fine-tune feeding regimes. Today, we use this simulation technology to establish digester and feedstock feasibility, as well as the optimization of existing systems.

Digester Rescue Service

Digester failures can be costly. The wrong feedstock can be detrimental to the methane-producing bacteria, and the digester will be producing too much gas or not enough. In some cases, the mix of feedstocks produces a gas that is more corrosive than a CHP can handle, leading to costly repairs.