China Xicheng EP Ltd products

Xicheng - Model WS-202101 - Packed bed scrubber

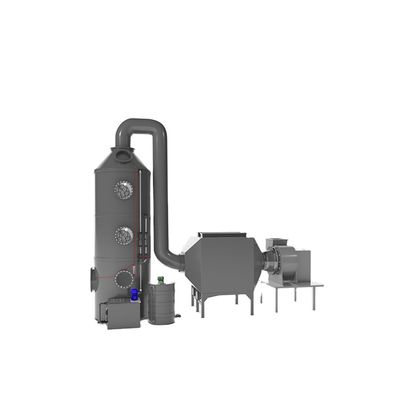

Exhaust gas treatment equipment - waste gas scrubber, spray tower, washing tower,Polyhedral ball packing: 1. Equipment introduction: The washing tower is a new type of industrial waste gas treatment equipment, which is widely used in industrial waste gas and dust removal, acid and alkali waste gas, painting industry, printing industry, pharmaceutical industry and other fields, the most commonly used and most practical processing equipment.It can effectively process HCL, HF, NH3, H2SO4, CrO3, HCN, NAOH, H2S, HCHO, etc.Various industrial organic waste gases and inorganic waste gases. 2. Structure and working principle The industrial waste gas enters the washing tower and is in full contact with the washing liquid in the tower to generate a neutralization reaction to achieve the treatment purification effect, effectively remove dust and other various gases, and finally meet the discharge requirements.Xicheng - Model PPS-2021 - PP Plastic Sheet - Beige

Introduction PP board (calcium plastic board): good size stability, low price, rigidity, heat resistance, etc. are better than pure PP. The color is generally gray and beige. Mainly used to make plastic water tanks, three-phase separators, industrial waste gas treatment equipment, ventilation pipes, washing towers and other products. Dimensions Product thickness: 3 ~ 30MM Length and width size: 1220*2440MMXicheng - Model WS003 - Wet Scrubber System

The polymer plastic wet scrubber system is mainly used to treat chemical waste gas discharged from industrial production. The PP wet scrubber can effectively remove HCL, HF, NH3, H2SO4, CrO3, HCN, NAOH, H2S, HCHO and other water-soluble gases.Xicheng - Model PPF202108 - PP anti-corrosion fan

PP anticorrosive centrifugal blower, bending strength is not less than 196 mpa, the surface of each part is smooth, without defects such as cracks, notches, burrs. The fan has reasonable aerodynamics, large volume, low noise, high efficiency, and corrosion resistance.XICHENG - Model XC-03 - PP Square Pipe - Customized

The PP square pipe adopts manual seamless welding technology, which has high cleanliness and good sealing performance. It can be used in air-conditioning ventilation systems and industrial exhaust gas emission systems. The square pipe can be flexibly customized for more special sizes. Square PP duct connection method Socket connection, that is, a PP sleeve is welded at the end of each section of the air pipe to facilitate the insertion of the next section of the air pipe; Flange connection, that is, a PP flange is welded at both ends of each section of the air pipe, and the screw-to-lock connection is used during installation. Convenient production, welding method for installation, firm, square PP duct flange connection, round and square can be customized Need to splice flange, easy installation, screw lock, easy to disassemble and maintain How to strengthen the square PP ductXICHENG - Model XC-04 - PP Plastic Sheet - Gray

Feature of product 1. Low density, easy to weld and process. 2. It has superior chemical resistance, heat resistance and impact resistance, non-toxic and odorless, and is currently one of the most environmentally friendly engineering plastics. 3. The main colors are white, microcomputer color, other colors can also be customized according to customer requirements. 4. Acid and alkali resistant equipment, environmental protection equipment, waste water and exhaust gas discharge equipment, washing towers, clean rooms, semiconductor plants and related industrial equipment, and also the first choice for manufacturing plastic water tanks. Among them, PP thick plates are widely used in stamping plates. , Punch mattress board and so on. 5. The material has the characteristics of high mechanical strength, rigidity, hardness, toughness, etc., good aging resistance and good mechanical shock absorption abilityXICHENG - Model XC-1 - Industrial Air Pollution Control System Wet Gas Scrubber

For a variety of corrosive gas purification treatment effect, can effectively remove hydrogen chloride gas (HCl), hydrogen fluoride gas (HF), ammonia gas (NH3), sulfuric acid mist (H2SO4), chromic acid mist (CrO3), cyanide gas (HCN), alkali vapor (NaOH), hydrogen sulfide gas (H2S), Fulmarin (HCHO) and other water-soluble gases. Washing tower purification efficiency is high, simple operation and management, long service life. The acid-base exhaust emissions after purification treatment meet the national emission standards.XICHENG - Model XC-1 - Exhaust Gas Treatment Wet Scrubber

Industrial waste gas treatment scrubbers have high purification efficiency, good corrosion resistance, lightweight, high specific strength, small footprint, and large waste gas treatment capacity. It is suitable for washing acidic waste gas, alkaline waste gas, and polluted flue gas in incinerators. The basic principle of industrial waste gas treatment scrubber is to make gas and liquid contact and transfer the pollutants in the gas to the beverage. The packing spray absorption tower is produced with PP as the main raw material, and the packing adopts PP material Pall ring or a hollow sphere. According to the gas absorption process at the gas-liquid two-phase interface, the transfer rate is proportional to the interface area. Fillers are used to increase the contact area of the two phases so that the two steps are fully dispersed. Then the clean gas is separated from the contaminated liquid to achieve the purpose of purifying the air.