CI Semi products

In-situ Wafer Temperature Monitoring

Advanced Non-contact Wafer Temperature Monitor

Advanced In-situ Emissivity Independent Non-contact Temperature Monitor. The NTM Delta is the only high accuracy and repeatability pyrometer which incorporates both real-time same-point emissivity and temperature measurement. Its design is based on CI Semi’s well-known NTM500, with thousands of installations worldwide. The Delta’s rapid update rate and small footprint make it ideal for demanding applications such as RTP. The high sensitivity and broad dynamic range allow low minimum temperatures to be accurately measured. Application- dependent algorithms allow for subtraction of interfering background radiation. The NTM Delta measures wafer temperatures in RTP, PVD, HDP-CVD, and other processes.

Advanced Non-Contact Low Temperature Monitor

The NTM-W is an infrared radiometer, optimized for temperature measurement of opaque targets starting from below room temperature. The high sensitivity and broad dynamic range allow very low temperatures to be accurately measured. Application dependent algorithms allow for subtraction of interfering background radiation. Flexible design for OEM applications, allows up to four probes to measure synchronically, providing a cost effective measurement of several targets, or the uniformity of a single target.

In-line Wet Process Concentration Monitoring

Wet Process Concentration Analyzer - Single Channel

CI -SEMI`s in- line, wet process analysis system, the WetSpec201, enables non-contact real - time monitoring and closed- loop control of chemical composition in wet process applications. The WetSpec201 is the single-channel version of the well known WetSpec200 and provides cost-effective, small footprint solution. The WetSpec201 is ideal for monitoring of cleaning, stripping and etching chemistries. Based on CI –SEMI’s novel algorithm, the WetSpec201 measures the absorption spectrum in the near infrared (NIR) fast and accurately without labor and material waste. The system’s versatile software models enable soft -switch between different chemistries. When integrated into a control and spiking system, the WetSpec201 enables tighter process control and identifies process excursions before they affect yield.

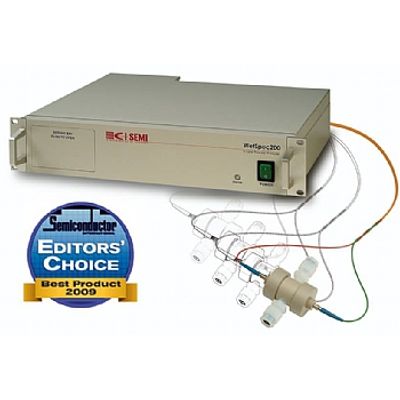

Multi Channel Concentration Analyzer

CI-SEMI’s in-line, multi-channel wet process analysis system, WetSpec 200 enables non-contact real-time monitoring and closed-loop control of chemical composition in wet process applications. The WetSpec200 is ideal for monitoring, cleaning and etching chemistries. Based on CI-SEMI’s novel chemo-metric methodology, the WetSpec200 measures the absorption spectrum in the near infrared (NIR) fast and accurately without labor and waste involved. The system’s versatile SW models enable soft-switch between different chemistries. With the capability to monitor up to eight flow cells in parallel, the WetSpec200 provides an efficient, low cost per channel process monitoring. When integrated into a control system, the WetSpec200 enables tighter process control and identifies process excursions before they affect yield.

Wet Process Monitoring System

The WetRad2 is an in-line, real-time, non contact concentration meter, using dual wavelength radiometery to enable cost-efficient monitoring of wet process chemicals. With its unique dual wavelength radiometer and by using pre-selected wavelengths, the WetRad2 is optimized to monitor a specific single component within a complex chemical mix. The WetRad2’s compact design is based on CI`s renowned and reliable NTM platform which is installed in thousands of process chambers working 24/7, for the monitoring of semiconductor processes. When integrated into a control system, the WetRad2 enables tighter process control and identifies process excursions before they affect yield.