Clarke Fire Protection Products, Inc. products

Fire Pump Engine Options

Clarke - Fire Pump Cooling Loop

The cooling loop you select for your fire pump driver is determined by your installation specifications. Clarke Cooling Loops are sized for each engine model based on the following standard conditions:

Clarke - Sound Attenuated Engine Enclosures

Check out Clarke`s new modular enclosures. Available in three standard sizes to cover our entire line of engines, Clarke Sound Attenuated enclosures have been re-designed to maximize engine performance while providing security and mechanical noise reduction. To come in 2019, Clarke enclosures will be available in similar lead times as our standard engines. Check out our submittal drawings and brochure below or contact Clarke for additional information.

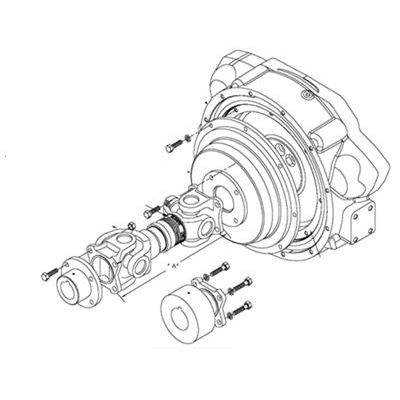

Clarke - Fire Pump Torsional Coupling

For drive systems with a right angle gear drive, there is the possibility of damage, due to natural frequency, when a torsional coupling is not installed. In reference to NFPA 20, vertical turbine pumps using angle gear drives, driven by a diesel engine, a torsional vibration damping type coupling shall be used and mounted on the engine side of the driver shaft (7.5.1.6.4). The torsional vibration damping type coupling shall be permitted to be omitted when a mass elastic system torsional analysis is provided and accepted by the AHJ (7.5.1.6.4.1).

Clarke - Model NFPA20 - Fire Pump Alarm and Gauges

NFPA20 2016 (11.2.5) requires diesel fire pump engine instrument panels to have at least a tachometer for indicating engine speed, an oil pressure gauge, coolant temperature gauge, and hour meter for recording engine run time. Clarke’s standard mechanical and electronic engine instrument panels comply with this standard. In addition, in compliance with UL1242 and FM1333, Clarke engines are designed to provide an alarm signal for high coolant temperature, low oil pressure, ECM warning and ECM Failure, raw water temperature alarm, and low flow conditions in the engine cooling loop

Clarke - Fire Pump Driveshaft Guards

Clarke Driveshaft Guards and Driveshaft Containment Guards are designed to provide protection against the risk of injury due to rotating mass. Clarke Driveshaft guards are designed for finger safe operation only and are constructed with easy to assemble aluminum panel pieces that connect directly to the engine flywheel housing assembly. With sizes to cover minimum collapsed lengths and maximum extended lengths, Clarke Driveshaft Guards flexible sizing is perfect for Clarke listed or nonlisted engine.

Clarke - Fire Protection Pneumatic Starting Systems

Clarke`s vigorously tested pneumatic starting system harnesses compressed air to provide a safe and reliable starting solution for your most sensitive fire protection applications. Clarke`s pneumatic starter can be applied in either a secondary or primary start system. When applied as a primary starter, Clarke`s UL Listed system meets NFPA20`s 180 seconds of continuous cranking.

Clarke - Battery Kits for Diesel Fire Pump Engines

NFPA20 11.2.7.2.1.1 states that all 12V diesel fire pump engines should be provided with two storage battery units. Each battery shall have twice the capacity sufficient to maintain a 3 minute attempt-to-start cycle (15 seconds of cranking and 15 seconds of rest, for 6 consecutive cycles) 11.2.7.2.1.4.