Clay Tech products

Brick and Roofing Tile Ind.

Box Feeder

Cement Ind

Clay-Shale and Limestone Crusher

Initially cement industry and so many mining industries can use this type machine. This machine can be considered as the primary crusher. It ensures that the first material coming from the mine, breaks 0-600 mm to 0-60 mm. Crusher is applicable for adhesive feed material The machine completely is produced with steel construction. The machine safety system has two different forms. The first one is designed with safety pin on the pulley by calculating mechanical energy and torque from the machine. The safety pin breaks when foreign material runs between the two rotors or when it is forced to break more raw material than medium hardness. The second is that due to the spring mechanism on which the bearings are based, the rotors act when the safety pins do not function. At this point the machine body or parts are still working without being damaged. Machine rotors produced from steel casting. The rotors, which are quite compact, are welded with special hard facing flux cored wires Scraper blades have been selected from special materials and welded with special hard facing flux cored wires to prevent sticking of raw material to the rotor due to moisture.

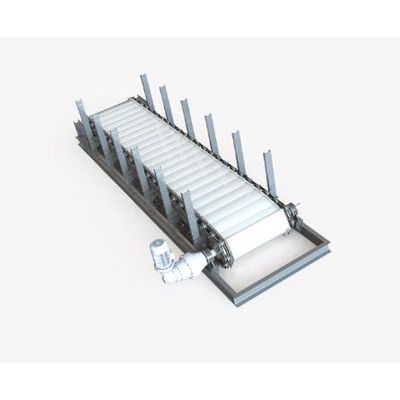

Apron Feeders

Clay Tech Apron Feeders are of rugged, heavy duty construction and designed to handle large lumps and where no fines removal is required or where fines are removed by a separate Scalper. When the feed material is wet, sticky or clay like, the Apron Feeder is the machine to select. Generally, the Apron Feeder can be installed in a horizontal or inclined position. The high inclination also allows to build compact installations and to reduce the length of the Apron Feeder keeping the investment costs low. As an optional extra, Clay Tech Apron Feeders can incorporate a Dribble Conveyor which is located under the feeder to catch the small pieces, fines and lumps of material that became trapped on the feed side of the apron flights and dribble out on the return side. This feature eliminates manual clean up and saves on man hours

Mining-Industry

Bentonite Plants

Our company can produce bentonite, which is a very useful natural product, on a turnkey basis or on a product basis. The clays that are formed as a result of chemical decomposition of volcanic ash, tuff and lava, rich in aluminum and magnesium, are defined as “bentonite”. Bentonite is a versatile clay used in industrial, agricultural, mining and engineering geology. The geological features and usage areas of bentonite vary according to the formation of Ca, Na and Na-Ca montmorillonites. Na bentonite with high swelling capacity swells 8-10 times its own volume in contact with water, while the rate of swelling in Ca-bentonites is 2-3 times. While Na and Na-Ca bentonites are used in drilling and iron powder pelletizing, they are used in works such as bleaching from Ca-bentonites, which have less swelling capacity, and are also commonly referred to as ‘bleaching earth-fuller earths’. By treating such clays with Na2CO3, the swelling capacity can be increased as a result of Na / Ca ion displacement. Bentonites are a type of clay that can grow up to 4-5 times its volume by absorbing water. They are divided into two as calcium bentonites and sodium bentonites according to their structural condition. Bentonites are used in many fields in industry such as casting sand, construction drilling, chemical industry, rubber industry, food industry, fertilizer industry, paint industry, ceramic industry. It is used for making cat litter, cosmetics and detergents today.

Brick and Roofing Tile Ind. - Crushing

Disintegrator

Disintegrator contains two parts: X Axial Movement Clay Crusher and Y Axial Movement Clay Crusher. X or Y Axial Movement Clay Crusher allows processing of the soil with any way used before and provides the separation of the soil in it. Clay Crusher is mostly used to clay from the mountain or as a pre-crusher. The production of bricks and roofing tiles is possible with disintegrator machine everywhere in the clay industry . Crushing clay materials in the form of clay stones into small pieces and preparing for material processing by separating foreign stones are also possible with its usage. Moreover the moisture or installation of the clay has no effect on the operation. They also storable after sprinkling the water to achieve broken clay, fast plasticity. Since the machine’s power consumption is thought, it contributes widely in the preparation of plastic clay. Disintegrator machine consists of two cylinders driven by two separate electrical motors. The clay blades pass through these cylinders after shredding operation. The large cylinder is set on a spring system that permits the necessary separation of the cylinders and the removal of excessive extrusions. Depending on the position of the springs, the big ball moves horizontally or vertically. In this way, it is possible to underline the safety against sudden loads.