Clean Gas Systems, Inc. (CGS) products

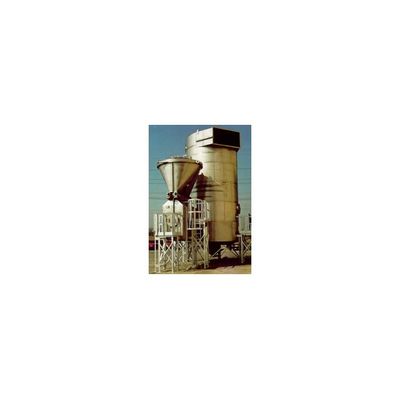

Cyclone Collectors

CGS - Single High Efficiency Cyclone Collectors

CGS Cyclone Collectors are designed to achieve high dust collection efficiencies at low pressure drops. We can satisfy the most stringent air pollution control laws and/or product recovery requirements. Our Cyclones incorporate a volute or tangential inlet. Collection efficiency depends on many factors such as operating pressure drop, cyclone barrel diameter, number of gas turns, gas density, gas viscosity, gas inlet/outlet velocities, dust particle density, inlet dust loadings, dust particle size analysis, saltation velocity, and overall cyclone dimensions.

CGS - Quad High Efficiency Cyclone Collectors

CGS Cyclone Collectors are designed to achieve high dust collection efficiencies at low pressure drops. We can satisfy the most stringent air pollution control laws and/or product recovery requirements. Our Cyclones incorporate a volute or tangential inlet. Collection efficiency depends on many factors such as operating pressure drop, cyclone barrel diameter, number of gas turns, gas density, gas viscosity, gas inlet/outlet velocities, dust particle density, inlet dust loadings, dust particle size analysis, saltation velocity, and overall cyclone dimensions.

CGS - Twin High Efficiency Cyclone Collectors

CGS Cyclone Collectors are designed to achieve high dust collection efficiencies at low pressure drops. We can satisfy the most stringent air pollution control laws and/or product recovery requirements. Our Cyclones incorporate a volute or tangential inlet. Collection efficiency depends on many factors such as operating pressure drop, cyclone barrel diameter, number of gas turns, gas density, gas viscosity, gas inlet/outlet velocities, dust particle density, inlet dust loadings, dust particle size analysis, saltation velocity, and overall cyclone dimensions.

Wet Scrubbers

CGS - Centrifugal/Vane Wet Scrubbers

This unit is suitable for low pressure drop applications involving heavy inlet dust loadings and slurry recycling; It achieves high collection efficiencies in the 2-5 micron range with low liquid rates. It utilizes a tangential gas inlet and stationary scrubbing vanes to induce centrifugal motion of the gas for removal of dust. There are no moving parts. It`s non-clogging, self-draining design makes it an ideal choice for many applications.

CGS - Impingement Wet Scrubbers

This is a low energy device that offers an advantage of particulate collection, cooling, condensing and gas absorption all in a single unit. Gases enter the unit from the bottom and flow upward through a series of trays, each containing perforations designed to achieve the highest efficiency with minimum pressure drop. Scrubbing liquid is introduced above the top tray and cascades downward to the lower trays. As the gases accelerate through the perforations, a fluidized zone of liquid and gas is created. The turbulent mixing in each of these zones provides intimate contact where gas scrubbing and cooling occurs. Units are furnished with a final demister section to minimize liquid carry over problems before the cleaned gases are exhausted via the top outlet.

CGS Ventriscrub - Venturi/Multi-Venturi Scrubber System

Conventional in every respect, this venturi scrubber features a wet approach inlet which eliminates wet/dry zone build-up problems. This unit can be furnished with a fixed, butterfly or two door venturi throat section; smooth or flooded elbow and a conventional cyclonic mist separator. Larger separators may be furnished with radial inlet and mesh pad or chevron type demister section.

Wet ESP

CGS - Model WESP - Wet Electrostatic Precipitator

Our Wet Electrostatic Precipitator provides 99% + removal efficiency for submicron particles at minimum pressure drop. For applications where a precleaning stage is required, CGS` Multiventuri Scrubber/Gas Absorber is included. CG-WESP utilizes an open Hexagonal Grid type Collector with 6` clearance between the surfaces. This Honeycomb type Collector Assembly provides the most powerful and structurally sound design with maximum collector surface area. Collector Grid Surfaces are not subjected to any pressure differential because the gases pass thru them on both sides. Our unique design does not require any tube sheets. Hence, a greater cross sectional area without any wasted space is provided. Two levels of gas distributors ensure uniform flow within the unit. A Flushing System incorporates spray nozzles that provide continuous cleaning with minimum liquid requirements in a co-current mode.

Primary Clarifiers

CGS Autodredge - Primary Clarifiers

CGS` primary clarifiers come with "heavy duty/rugged" construction as a standard feature for a longer life. A chemical floculation system is also available to maximize performance.