Clemco Industries Corporation products

Contractor - Portable Abrasive Blast Machines

Clemco - Portable Abrasive Blast Machines

Ideal machines for quick or touchup jobs, light-duty blasting, if you don’t have access to a large air compressor, or for hard to get to jobs—like when you need a portable machine that you can carry up 10 flights of steps to surface prep structural beams or to roll alongside a pipeline when cleaning up welds to satisfy an inspector. These machines are easy to store and transport, and to maneuver around job sites. Designed for contractors who often wear several hats, and blasting is just one of their many responsibilities.

Clemco - Abrasive Blast Machines

Throw these machines into your pickup’s bed and you’re off to the job site—whatever it may be. Designed for maneuverability, mobility, and versatility—but when you need more capacity than smaller blast machines. Half-day jobs, cleaning buckets on excavators, tractors or skid steers, abrasive blasting dump truck or dirt trailers, pipeline maintenance, surface prepping infrastructure, or rehabbing buildings—Clemco’s 3-cuft Classic Machine is for you. Need more durability, capacity, and mobility? Try the 4-cuft Contractor Machine. It’s also perfect for rental yards.

Clemco - Abrasive Blast Machines

For contractors whose main source of income is a variety of abrasive blasting. These machines can handle small or large jobs, light-duty or high-production. Stage your Clemco 6-cuft machine near pipelines for maintenance or building structures for rehab work. Clean the interior or exterior of wastewater treatment tanks or ship hulls, or blast an entire trailer or excavator for rehab. These machines excel at blasting small bridge and overpass structural components. If you need a 6-cuft machine that is easier to load, choose the 6-cuft Lo-Pot Machine. Need a 6-cuft machine built with extra durability and mobility—or if you own a rental yard—the 6-cuft Contractor Machine is for you.

Abrasive Recovery System

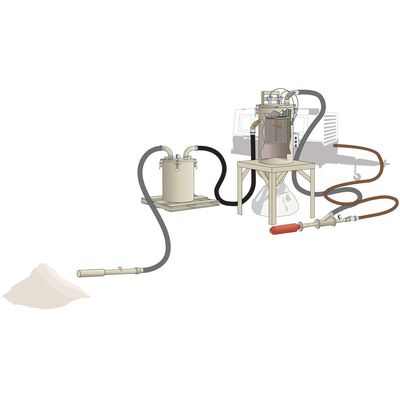

Clemco Munkebo - Portable Abrasive Vacuum Recovery Systems

Your abrasive recovery just got quicker and easier. Removing spent abrasive for disposal or recycling is a pain. And when it takes too long, it eats away your time and profits. In fact, cleanup after a blasting job can run up to 40% of a project’s total cost. Munkebo Portable Abrasive Vacuum and Recovery Systems make recovering spent abrasive quick and easy, saving you time and money. Productivity and Performance: Think of Munkebo Abrasive Vacuum Systems as giant vacuum cleaners. Their recovery hoses easily get to where abrasive is lodged or hidden—places that would be nearly impossible to recover abrasive from with manual or mechanical methods—and Munkebo Systems are faster!

Blast Machine Abrasive Loading and Recovery

Clemco - Low to Medium-Production Abrasive Loading or Recovery

Operation – Vacuums up abrasive into a 6-cuft media storage hopper for either: Disposal or transfer to a recycling system. Loading the collected media into a blast machine placed underneath the hopper. System Components – In addition to a 6-cuft media storage hopper, the ELS-2-290 comes with a reverse-pulse dust collector and a media pickup tool that can be attached to an included media loading hopper.

Clemco - High-Production Abrasive Loading or Recovery

Operation – Vacuums up abrasive into a 17-cuft media storage hopper for either: Disposal or transfer to a recycling system. Loading the collected media into a blast machine placed underneath the hopper. System Components – In addition to a 17-cuft media storage hopper, the ELS-4-290 comes with a reverse-pulse dust collector and a media pickup tool that can be attached to an included media loading hopper.

Clemco - High-Production Abrasive Loading or Recovery

Operation – Vacuums up abrasive into a 6-cuft collection container for disposal or for transfer to a recycling system. System Components – In addition to a 6-cuft collection container, the ELS-6-290 comes with a reverse-pulse dust collector and a media pickup tool.

Blast Machines

Clemco - Cuft Big Clem Bulk Blast Machines

Clemco makes Bulk Blast Machines that outperform every competitive unit on the market. Clemco’s extensive inventory of manual, automatic and remote controls allow flexible configurations to match large scale production needs exactly. A built in Pop-Up valve for quickly loading abrasive and an optional operator controlled Abrasive Cut-off Switch operated at the blast nozzle are a boost to production rates, drastically cutting back on down time.

Clemco - Cuft Big Clem Bulk Blast Machines

Clemco makes Bulk Blast Machines that outperform every competitive unit on the market. Clemco’s extensive inventory of manual, automatic and remote controls allow flexible configurations to match large scale production needs exactly. A built in Pop-Up valve for quickly loading abrasive and an optional operator controlled Abrasive Cut-off Switch operated at the blast nozzle are a boost to production rates, drastically cutting back on down time.

Operator Safety Systems

Clemco - Ambient Air Pump

The Apollo Ambient Air Pump conveys breathing air from a clean environment outside the work area to a low-pressure type CE supplied-air respirator worn by an operator inside the blast environment or work zone. The oil-less pump moves the air from a clean-air environment to the respirator without introducing oil, carbon monoxide, or other contaminants.