Cleveland Cascades Ltd. products

Free Fall Chutes

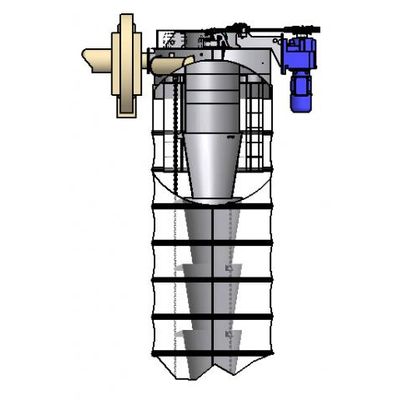

Cleveland - Model C Series - Vertical Cone System

The Free Fall C system utilises a series of cones and the modular design used in a Cascade system. But instead of being inclined, the cones are vertically suspended from chains or strops, allowing the material to fall vertically to the pile. Externally an outer shroud allows for the air displaced during loading to be captured and maintained. If the application is sensitive to dust emissions, the shroud allows for a dust extraction system to be fitted, to ensure dust free loading.

Cleveland - Model T Series - Telescopic Tube System

The Cleveland Cascades T Series Free Fall Chute comprises of a series of telescoping concentric tubes. It is supported at the head chute interface point and can extend and retract to suit the length required for each loading job. Unlike the modular Free Fall C Series, the Chute remains rigid and is ideally suited to applications which require Trimming Spouts or Jet Slinger devices. The T Series incorporates a scraper/brush cleaning system at the head of each tube, which is beneficial for particularly sticky materials, where periodic cleaning is an issue.

Tanker & Vehicle Loading Chutes

Cleveland - Model TL Series - Tanker Loading Chutes - Vertical Cone System

Cleveland Cascades Tanker Loading Chutes utilise the same vertical cone design, used in the C Series Free Fall Chute. The Free Fall principle is highly effective when loading in to the enclosed space of a Tanker. The system is fitted with a completely sealed closure cone which connects to the tanker inlet.

Cleveland - Open Vehicle Loading Chutes - Cascade or Free Fall

The loading of dry bulk material into open vehicles, whether road or rail, is an area of the industry which is susceptible to problems of dust creation, material degradation and separation as well as over-filling and spillages. Cleveland Cascade loading chutes can provide an effective high performance solution to meet all of these challenges. Depending on the application and the material being handled we can offer our Cascade, controlled flow technology chute or our Free Fall vertical cone system. The cone material supplied can be agreed during the quotation process, but might include wear resistant liners and protection against corrosive materials such as Urea or Sulphur.

Free Fall Chutes - Options

Cleveland - Model C - Outlet Dust Extraction Units

In applications which require both a relatively lightweight chute and where dust pollution needs to be controlled, Free Fall C series chute fitted with Dust Extraction Units can be an effective solution. The extraction unit is carrier-mounted at the base of the Chute (Outlet). This is the optimum position for dust extraction, right at the source of the dust creation. The rate of dust extraction and the specification of the extraction unit can be agreed during the enquiry phase to meet the requirements of the job.

Cleveland - Model C - Head Chute Dust Extraction System

The system has been developed in conjunction with Donaldson Filtration Systems, the leading global specialist in Filtration Technology. It is integrated in to the head chute and comprises a fan motor, compressed air manifold along with up to nine filters & diaphragm valves which are controlled via an Integrated Pulse Controller (IPC).