Coating Tech Slot Dies products

Slot Dies

Fluid Delivery System

The fluid delivery system works with the slot die to control cross-web caliper variation and web handling and tension control to control down-web caliper variation in self metered, fluid coated products. The fluid delivery system is a combination of a pump, filter, flow meter, pressure transducers, volumetric tank, fittings and hoses that develops a pressurized flow of liquid for coating application. CTSD can help analyze and design and manufacture all or some of the fluid delivery cart equipment required for precision coating.

Coating Stations

Slot Die Positioner

Repeatability and accuracy within 0.0001 inch (2.54 microns), Roll or free span coating capability, On/off coating control, Splice jump, Slot die to roll adjustment via ball screw adjustment slides, Stainless steel construction, Precision linear bearings for slot die movement, Pneumatic actuation, Dual dial indicators, Vacuum box, Single chamber, Adjustable precision machined Teflon vacuum blade located under the coating roll with adjustment to change the gap between the vacuum blade and the substrate, Teflon end seal to seal die with backing roll, Two stainless steel tanks (one for drain and one for baffle), One regenerative blower including filter housings, filters, mufflers, and variable frequency drive)

Coating Station with Precision Roll

Rigid side frame construction equipped with leveling and mounting taps.

Parts + Accessories

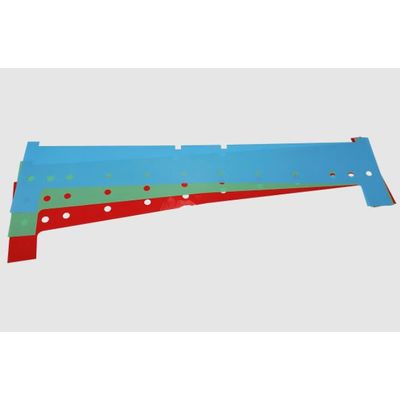

Die Body Shims

Shims control the most critical component for slot die coating application – the slot gap. The precision and flatness of the shim is important for optimum coating control. Utilized in fixed lip slot die coating equipment, CTSD can provide a precision manufactured part for any slot die equipment that needs the functionality of a slot die body shim.