Cobey Inc products

CNG Products

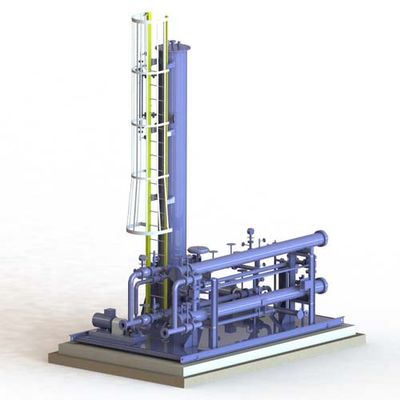

Cobey - CNG Compressor Package

Each Cobey Energy CNG Compressor Package is designed with maintainability and reliability at the forefront. Simplicity of operating a Cobey Energy Natural Gas Compressor is paramount and considered in every design. Custom engineered designs are also available to meet your unique CNG station site requirements. Cobey Energy’s CNG compressor module is built to the highest standards and is designed to meet or exceed NFPA 30A, 52, 70, SAE J1616 and ASME Section VIII, Div. 1.

Cobey - CNG Fas Fill Dispenser

Cobey Energy designs and manufactures CNG compressor station equipment systems for station developers, end users and specifying engineering firms. With more than 30 years experience in engineering, design and manufacturing of high pressure compressor packages and auxiliary systems for the Oil & Gas, Petrochem and Power Generation markets, Cobey Energy is well equipped to meet your CNG application requirements.

Other Products

Cobey - Compressor Packaging System

Packages could include structural bedplate, machinery mounting pads, piping, tubing, electrical wiring, instrumentation, controls. Modular design reducing field installation and equipment transportation costs. Cobey has built hundreds of Compressor Packages for Oil & Gas, Petrochemical, Air Separation, and Power Generating Industries.

Cobey - Cooling Water Systems

Cooling water systems are designed to circulate cooling water to various types of industrial rotating equipment. Typically, these systems include pumps, heat exchangers, filters, controls and instrumentation. Built under controlled conditions in a fabrication facility, systems are mounted on structural steel bases designed for easy and safe transport to the end-user`s facility. This "modular" concept reduces start up time and costs in the field, and allows the end-user to take advantage of our OEM expertise and fixed costs.

Cobey - De-Noxification Systems

De-noxification systems are used to reduce the nitrous oxide emissions from the discharge of electrical power generators. The units consist of high volume, low pressure blowers and a pressure controlled liquid ammonia stream. The stream is injected into the waste gas upstream of a catalyst to obtain government regulated discharge levels.

Cobey - Gas Conditioning Skids System

A Gas Conditioning Skid is designed to pre-treat natural gas and other combustible gasses prior to injecting into a critical process or a Gas Turbine Generator. The skid performs two functions; remove all liquid droplets and solid contaminants from the gas, and adjust the gas temperature to the injection requirements. Different styles of filter elements can be used in the pressure vessels. The liquid contaminants are collected in a sump and automatically drained from the system for easy operations. Either electric or steam heaters can be used for temperature adjustment. All of the system components and piping are skid mounted for transport and installation.

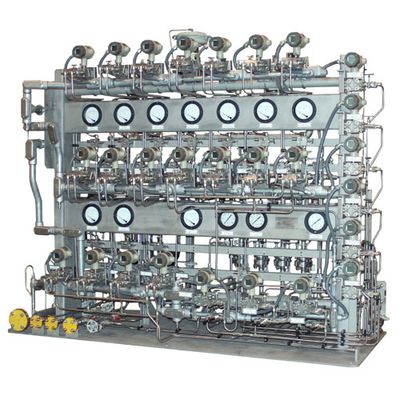

Cobey - Gas Seal Panels

A Cobey Gas Seal Panel is designed to supply seal buffer gas to the shaft seals of various rotating compressors, providing containment of these process gases. The panel includes filters, pressure/flow control valves and various instruments to condition, control, and monitor the gas into and out of the dry gas seals. Arranging all of the instruments in one location near the compressor package simplifies the mechanical, process piping and electrical installation.