ColVisTec products

Process Monitoring Technology

The old fashioned way of quality process monitoring included taking samples and analyzing them in a laboratory which prevented factories to fully control the quality of their outcome. The process was inefficient, long, and costly. This measurement procedure was repeated approximately every 2-3 hours. Compare this turnaround time to the efficiency of our technology, and you will immediately understand the benefits.

Inline Spectroscopy

ColVisTec - Spectrophotometer System

Spectrophotometer: Millennium 3 UV-VIS with CCD. spectrum (Renectanc©): 380 through 780 nm. Spectrum (Transmission): 220 through 820 nm (Optional). Resolution: 1 nm. Spoctromotor: Optical Grating.

ColVisTec - Color Probe (CP) System

CP is used in extruders for opaque liquids, paste, powder, and pellet materials.

ColVisTec - Reflection Polymer Melt Probe

Probe Tip: Standard Dynisco. Thread l/2"-20 UNF. Sapphire Window (Self Cleaning by Material Flow). Separate Fiber Optic for Easy Calibration Temperature: < 400 °C Pressure: < 200 bar Illumination with Xenon Flash Lamp Six Circumferential Positioned Glass Fibers for Illumination Center Positioned Fiber for Reflectance Standard Fiber Length: 5 m Maximum Fiber Length: 20 m

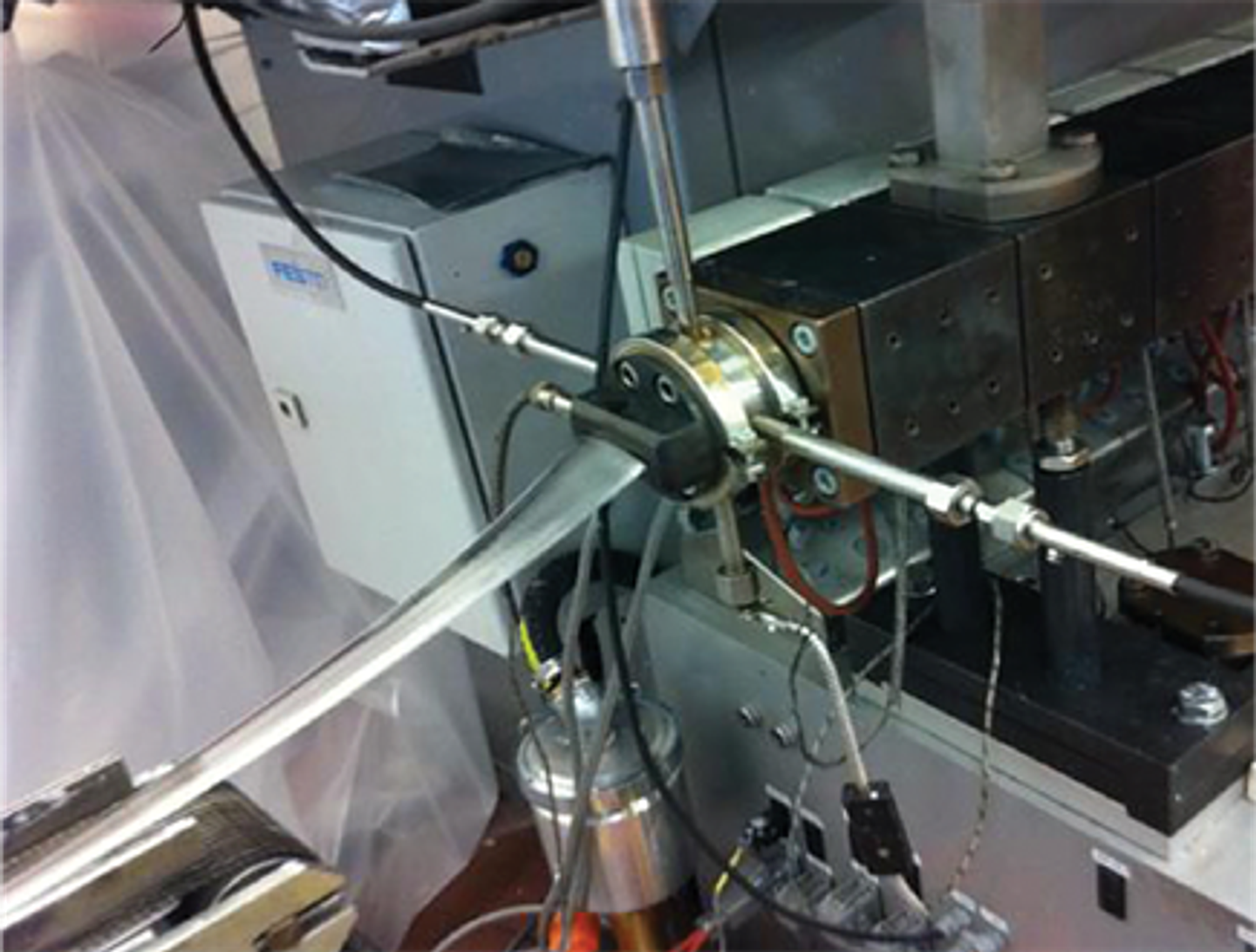

ColVisTec - Transmission Polymer Melt Probe

Consists of Two Fibre Optic and Two Probe Body Units. Sapphire Window. Fibre Length: Each 5 m. Stainless Steel Body.

Thread Probe Tip: W - 20 UNF (typ. Dynisco"). Length of the Probe Body: 152.5 mm. Requires Perfect In-Line Fitting. Temperature: < 400 °C. Pressure: < 200 bar.