Compatible Components Corporation (CCC) products

Mixing + Blending

CCC - Bulk Bag Handling System

The Bulk Bag Handling System is designed for the efficient and safe handling of bulk bags. When lowered into the docking station, the bulk bag is automatically pierced by the system, ensuring a rapid and contained extraction of the powder contents. The system integrates with the HydroDyne Jet Pump, facilitating a seamless transfer of materials through a hermetically sealed suction assembly. Notably, the system operates under patent number 8,622,715, offering a unique approach to bulk material handling by combining robustness with precision. This design minimizes contamination risks and operational downtimes, making it suitable for industrial applications that demand high throughput and strict adherence to safety protocols. Available models include the C-BBS-45CF-04A and C-BBS-45CF-06A, each tailored to specific handling requirements.

CCC - Model AZ - Mixing Eductor for Hydration and Dispersion

The AZ Mixing Eductor is engineered to provide efficient mixing, hydration, and dispersion by leveraging a conventional centrifugal pump or rotary gear pump. Unlike traditional systems that rely on mechanical shear, the AZ Eductor employs a non-circular nozzle to generate twin opposing vortices. These vortices interact to enhance fluid stretching and folding, which in turn increases interfacial contact and promotes rapid hydration. The process ensures uniform dispersion of slurry and improves slurry stability. This eductor is suitable for a wide range of applications, offering improved quality and cost reductions. It's available in multiple sizes ranging from 1 inch to 6 inches, allowing for versatility in different operational contexts. The product is patented under Patent No. 8,622,715, reflecting its unique design and functionality.

Separating + Dewatering:

CCC - Urethane VorSpin Hydrocyclones for Sand and Silt Removal

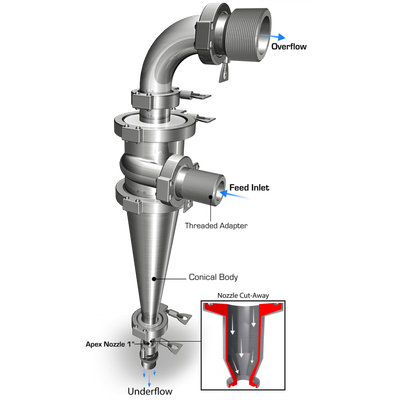

VorSpin Hydrocyclones are engineered for simplicity and reliability, serving various industrial applications by utilizing centrifugal separation to efficiently classify and remove suspended solids in a slurry. The Urethane VorSpin model is particularly adept at handling tasks such as sand and silt removal, drilling fluid solids elimination, catalyst separation, and soil washing. This model incorporates three key enhancements to improve hydrocyclone efficiency: the Volute feed inlet reduces turbulence by preventing slurry backflow, the Fluted Vortex Finder accelerates particle separation by increasing the momentum of the swirling slurry, and the Non-plugging discharge Apex mitigates core plugging through its unique orifice design and differential pressure regions. These features collectively enable a more effective separation process, enhancing the overall performance in industrial applications. VorSpin offers additional resources, including performance charts and brochures for further insights.

CCC VorSpin - Stainless Steel Vorspin Hydrocyclones

The VorSpin Hydrocyclone Series utilizes centrifugal separation principles for efficient removal or classification of suspended solids in slurries. These hydrocyclones are designed with three key features to enhance performance: a Volute feed inlet that minimizes undesirable turbulence, a Fluted Vortex Finder that accelerates separation by increasing slurry momentum, and a Non-plugging discharge Apex that prevents blockage via a differential pressure region. The stainless steel construction ensures durability and resistance to abrasion, making these hydrocyclones suitable for applications such as sand and silt removal, drilling fluids solids removal, and catalyst removal. Engineers and project managers in various industries value these hydrocyclones for their simplicity and absence of moving parts, which translates to lower maintenance requirements. The VorSpin Hydrocyclones are available in both stainless steel and high-density urethane to meet diverse operational needs.