- Home

- Companies

- Concord Screen

- Products

Concord Screen products

Wedge Wire Screens - Treatment & Media Retention

Concord - Profile Screen Laterals

Concord Screen uses its wedge wire screen to manufacture Hub and Lateral assemblies. Typical configurations include both horizontal herring bone style and vertical secured round hub. Concord Screen recognizes the specific needs of each and every customer. With an onsite ability to form wire. Concord Screen is able to control all variables in the wedge wire screen manufacturing process. Standard sized wires are available to complete a full range of wedge wire screen diameters and lengths.

Concord - Header Assembly Screens

In horizontal installations a main header is typically bolted into a longitudinal vessel. The header is supplied with welded couplings to accept either screen laterals or pipe based screen laterals.

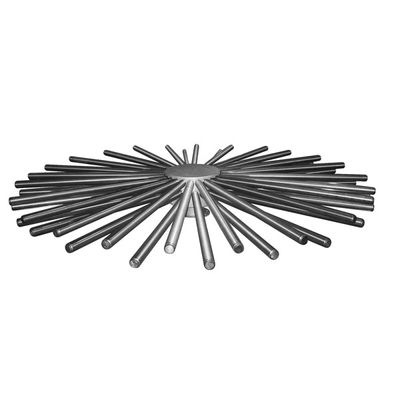

Concord - Hub Assembly Screen

with a vessel mounted upright the pattern required of the under drain assembly is round. This style is achieved with a central hub. Again couplings are typically welded to the hub to accept either wedge wire screen laterals or pipe based laterals. Screen Lateral As an efficient collector, the screen lateral is available in several sizes, with various slots and end fittings. Most commonly, the screen lateral is provided with a solid cap on one end and a threaded pipe connection on the other end. Pipe Based Lateral Screen laterals are supplied with an internal or external distributor pipe when extra strength and/ or more effective back washing distribution are required.

Concord - Flat Support Grids

Flat Support grids are available in single one piece construction. Typical Designs are fabricated in sections to allow installation through a mainway. Sections are fitted with flange support frames. During installation the sections will be laid flat on an existing vessel support structure. Sections will be bolted together creating a single complete support grid. With each application loading requirements change. Support grids are available with many different wire configurations to achieve the most demanding loads. Additional supports are often utilized to accommodate extreme load conditions.

Concord - Nozzles & Orifice Plates

Nozzles are installed in a vessel orifice plate. Typical configuration has a stem projecting through each orifice and secured with a nut and washer. Screens are manufactured to suit customer requirements and are not restricted in size by length or diameter. Typical screens are fabricated with a blind cap on one end and washer fixed with a threaded stem on the other end.

Wedge Wire Screens - Intake Screens

Tee Intake Screens and Drum Intake Screens

Simplify your approach to the design and manufacturing of intake screens for your operation. Concord Screen is the major manufacturer of high quality wedge wire intake screens. Concord Screen custom designs and builds for all types of industrial facilities requiring intake water including nuclear, hydroelectric, coal, gas, oil and chemical plants, pulp and paper mills. And public and private water companies. Concord Screen`s seamless design and build capability saves you the time and hassles of having to coordinate and deal with separate sources, while providing cost-efficiencies as well. Bring your intake screen requirements to Concord Screen for a complete turnkey solution.

Wedge Wire Screens - Industrial & Architectural

Concord - High Performance Wedge Wire Construction Screens

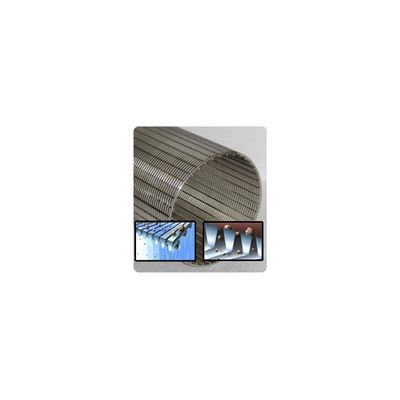

Concord Screen`s wedge-shaped wire design provides maximum open intake area. In a wedge wire application, the debris is filtered by the smooth side of the standard wound wedge wire element. The screen`s vertical support rods are rigidly welded at every intersection, giving a smooth surface to further enhance the free flow of water. Our exclusive, high-tech welding technique also delivers a screen with outstanding strength and resistance to corrosion.

Mining and Mineral Processing Wedge Wire Screens -

Carbon Retention Screen Basket for Cyanide Leaching Process (CIP or CIL)

Concord Screen is dedicated to working with mineral processing industry. Our ISO certified products are manufactured in Ontario Canada. CSI`s wedge wire screens have been improving the performance of existing screening equipment across the industry for over 30 years.

Flat Panel and Sieve Bend Wedge Wire Screen

Only two points of contact make wedge wire screen better with benefits of: low maintenance, reduced down time, superior integrity, prolonged service life.

Wedge Wire Screens

Media Retention Screen

As an efficient collector, the screen lateral is available in several sizes, with various slots and end fittings. Most commonly, the screen lateral is provided with a solid cap on one end and a threaded pipe connection on the other end. Pipe Based Lateral: Screen laterals arc supplied with an internal or external distributor pipe when extra strength and/or more effective backwashing distribution is required. Open Area of a Concord Screen . To determine the open area of your Concord Screen, divide the slot opening size by the sum of the slot opening size plus the profile width of the wrap wire, then multiply the result by 100.