Conveyance Solutions by Continental products

Screw Conveyors

CSC - Screw Conveyors

Screw conveyors are designed to have material loaded into them by a controlled feed, receiving a uniform and continuous amount of product. We specialize in building heavy duty units for particular applications, designing each unit to meet specific requirements.

CSC - Screw Feeders

Screw feeders are set up to be flood fed, so that regardless of the amount of material in a hopper above the inlet the output rate will remain constant. It is this trait that makes screw feeders a critical part of a system, as they set the rate of material flow for the rest of the equipment downstream.

CSC - Multi Screw Units

Multi-screw feeders share features of standard screw feeders along with additional benefits: Able to unload from a wider inlet than a feeder with a single screw. Can help reduce stackup height (multiple small screws can equal the outlet of single larger screws). Often used to handle challenging materials such as woodchips and compost..

Bucket Elevators

CSC - Centrifugal Bucket Elevators

Centrifugal elevators are used to handle fine free flowing materials. The buckets travel at speeds high enough to discharge material by centrifugal force as they pass around the head sprocket/pulley. Casings can be made from carbon steel, stainless steel and other harder materials as required by the application.

CSC - Continuous Bucket Elevators

Continuous elevators are used to handle heavy materials with large lumps. The buckets travel at lower speeds to allow for minimum material degradation and reduced wear on equipment. The main advantages of a continuous elevator over a centrifugal elevator are the large lump size capacity and the gentle manner in which the material is conveyed. In both chain and belt versions of the continuous elevator the backside of a bucket helps form the discharge chute for the following bucket.

Belt Conveyor

CSC - Standard Belt Conveyors

We offer standard idler type belt conveyors known for moving large amounts of material with a minimal amount of HP. These conveyors can be provided as small capacity 18" feeders with a short single welded channel frame assembly to high capacity 48" wide conveyors several hundred feet long with 20`-0" or 40`-0" truss sections.

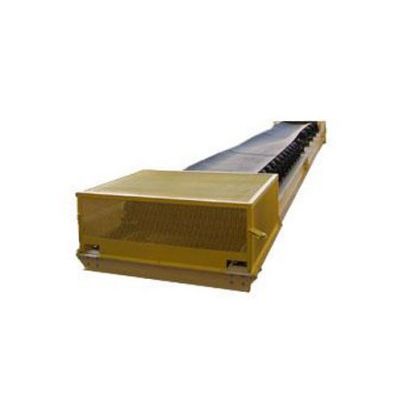

CSC - Enclosed Belt Conveyors

Enclosed belt conveyors are useful where dust containment and product isolation are priorities. Different from standard conveyors with covers attached, enclosed units feature an integrated cover which is part of the conveyor structure itself. These units offer the dust containment benefit of a screw conveyor without the risk of product degradation during the conveyance of material. Available in carbon and stainless steel construction, units can be placed in horizontal or inclined installations.

CSC - Air Slide

Continental in cooperation with Martin Engineering has the ability to offer air supported belt conveyors. This type of conveyor is unique in that it has no moving parts on the inside of the conveyor. The belt is supported on a film of air, thus reducing friction and decreasing HP while improving operating performance.

CSC - Flexible Sidewall Pocket Belt Conveyors

With sidewall heights up to 24" tall and belt widths up to 72" wide the CSC flexible sidewall pocket belt conveyor is ideal for conveying and elevating bulk material in all types of industries. These type of belt conveyors are used extensively in the power, cement, steel mills, scrap recycling, pulp & paper mills, mine processing and many other industries. Flexible sidewall belt conveyor require less horsepower than other types of conveyors and can elevate bulk material up to a 90 degree incline.

CSC - Drag Conveyors

Drag conveyors are designed to convey a high volume of material requiring much smaller amounts of space. Material is moved as a large mass with no internal turbulence, at low speeds. The high capacity and lack of turbulence allows the drag conveyor to handle almost all types of bulk material and can be used to meter or transfer bulk materials from one process to another. The design allows drag conveyors to fit almost any plant layout. Minimal long term maintenance and durability are characteristics of a drag conveyor.