Corporate Engineering Ltd. products

Cover

Conical Covers

Simple, economical GRP covers for your tank. Corporate Engineering supply a range of conical GRP covers. Where simple odour containment covers are required, conical covers can be an economical option. Conical covers are available up to 16.1m diameter, and covers up to 20m diameter are coming soon. Should you need more details regarding this, please do not hesitate to contact us.

Beam and Infill Covers

A flexible solution to covering any shape of tank or chamber. A flexible solution to covering any shape of tank or chamber. The beam and infill system offers a flexible solution to covering any shape of tank or chamber. The B&I system spans up to 25 meters and is totally self-supporting. The system allows for covers to be fitted without the need for emptying or cleaning the tank as no access inside the structure is required. Beam and Infill covers have a very low profile that reduces the air space below t a minimum and has a very low visual impact.

Inlet Works for Bespoke Covers

Bespoke covers for every project. No two inlet works are the same. Each one needs to have covers specifically designed for it. Whether the covers are to fit a newly built inlet works or are to be retrofitted to an existing structure, Corporate Engineering can develop a design concept to suit the each application. For new works, we are happy to offer advice on the inlet work’s design to enable efficient covering to minimize odour escape. By following some simple guidelines, the efficiency of the covers can be increased dramatically while keeping costs to a minimum.

Chamber Covers

To provide access for safe operation. Pump chambers and wet wells can be quite complicated and difficult to cover effectively. Corporate Engineering can design covers that provide access for the safe operation and removal of pumps and other equipment while accommodating pipework penetrations and guide-rails.

Fiberglass Rotating Covers

This type of cover is ideal when moving equipment is fitted within the tank. Specialised fiberglass covers for projects with a scraper system. Rotating covers are made when a fixed beam and infill or conical cover does not suffice - when a rotating scraper system is required. This specialised GRP cover can be fitted with bespoke access hatches, vented cowls and connection flanges. Personnel access areas treated with non-slip for safety. Extremely environmentally and chemically robust, and finished with chemical-resistant, water-resistant, and temperature resistant resins.

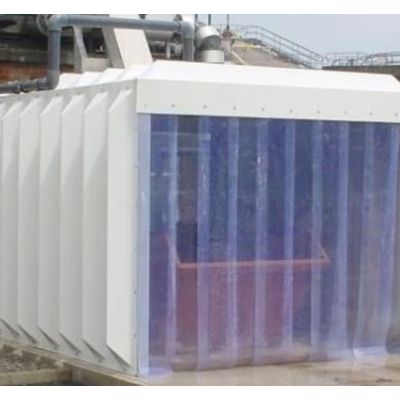

Skip Enclosures

Can be adapted to incorporate grit chutes and ducting. Screenings skips can be difficult to cover while allowing the skip to be replaced easily. Corporate Engineering designs and manufactures simple GRP skip enclosures to suit the requirements of each site. The basic unit consists of corrosion resistant GRP panels that create the enclosure’s structure. PVC strip curtains at the front allow the skip to be easily removed and replaced. Enclosures can be adapted to incorporate grit chutes and ducting. Odour extraction pipework can be connected at any location to suit the site layout.

Hybrid Fabric Covers

Modified fabric covers for inspection. Corporate Engineering’s standard GRP covers can be modified to incorporate fabric covers. Fabric covers have been developed to meet the needs of operations personnel where large areas of a cover need to be opened for inspection and to give the operators a clear view of the process. The operation of the fabric section is designed to be a one-person procedure and to require minimal effort. With only 3 moving parts, maintenance is kept to a minimum. When closed, the fabric is tensioned to prevent ponding and ice formation.

Stainless Steel Sliding Covers

Manufactured from corrosion resistant materials. For some applications, inspection hatches sometimes do not provide sufficient access to the chambers or any equipment below. Corporate Engineering have supplied many sliding covers to such areas. Sliding covers can solve some operational problems but can create several others. Odour tightness and safe operation are just two issues that need to be considered. Corporate Engineering can advise the best solution for each application. CEL only use components that can survive the demanding conditions found on all sewage treatment works. Any steelwork is stainless steel (Grade 316) and all running gear is similarly corrosion resistant.