- Microcor- High Speed ER Transmitters

- Data Loggers - Standard Electrical Resistance (ER)

- Portable/Handhelds - Standard Electrical Resistance (ER)

- Portable/Handhelds - Non-Intrusive Ultracorr- Ultrasonics

- Probes - Microcor- High Speed ER

- Probes - Standard Electrical Resistance (ER)

- Corrosion Coupons - Sensors - Cosasco Real-Time Non-Intrusive

- Corrosion Coupons - Sensors - Atmospheric

- Corrosion Coupons - Sensors - Corrosion Under Insulation

Cosasco products

Microcor- High Speed ER Transmitters

Cosasco Microcor - Model M-310 / M-320 (MWT-3905) - High Speed Wireless Transmitter

Microcor wireless transmitter is based on Cosasco’s flagship corrosion and erosion measurement technology. It delivers real-time, continuous data directly from the field.

Data Loggers - Standard Electrical Resistance (ER)

Cosasco - Model ER-210 - Electrical Resistance Remote Data Logger

Electrical Resistance Remote Data Logger (ER-210) is ideal for any monitoring location on where online communications are not feasible. The instrument can be configured to take readings as frequently as every five minutes. Programming and data retrieval from multiple ER-210 data loggers is accomplished using a single Checkmate™ DL for direct transfer to a portable or desktop P.C. running Cosasco Data Offline Software.

Portable/Handhelds - Standard Electrical Resistance (ER)

Checkmate - Model DL - Portable Electrical Resistance (ER) Instrument

The Checkmate DL handheld instrument is the convenient and hassle-free way to program and collect data from Microcor Data Loggers or ER and LPR Remote Data Collectors (RDC). Checkmate DL can be programmed to operate with either technology with only a few button clicks.

Portable/Handhelds - Non-Intrusive Ultracorr- Ultrasonics

Cosasco - Non-Intrusive Underground Pipe Thickness Monitor

Ultracorr utilizes high sensitivity ultrasonic technology to provide non-intrusive monitoring of corrosion and erosion. The instrument can be used to log multiple transducers from a common connection point, to provide periodic time and date stamped measurements of wall thickness. Ultracorr is ideally suited to form the backbone of an ICDA asset integrity system for pipeline operators. Sensors are permanently attached to the exposed surface in areas such as low lying spots, drips on other locations where corrosion should be monitored.

Probes - Microcor- High Speed ER

Microcor - Model M4000, M3000, M2000 Series - High Sensitivity Probe

The high speed probe is an integral component of Microcor. Two styles of probe elements are available –flush and cylindrical. Flush probes are optimal in high temperature and cylindrical probes are suited to more aggressive environments.

Probes - Standard Electrical Resistance (ER)

Cosasco - Model 2500/2500HT - Fixed Process Electrical Resistance (ER) Probe

Model 2500 fixed process probes have a thin walled cylindrical sensing element which is welded onto a body of the same material. No other materials are in contact with the corrosive medium. Welds are vacuum annealed during assembly to avoid preferential corrosion effects.

Corrosion Coupons - Sensors - Cosasco Real-Time Non-Intrusive

Cosasco - Fixed Point Ultrasonic Sensors

Fixed point ultrasonic sensors measure absolute wall thickness providing market leading resolution for wall thickness loss. Systems consist of multiple ultrasonic sensors organized in a customized matrix to cover either a bend, straight pipe, weld, T-piece, vessel or a tank.

Corrosion Coupons - Sensors - Atmospheric

Cosasco - Model 610 - Atmospheric (ER) Corrosion Sensor

The Atmospheric Corrosion Sensor monitors the corrosivity of the air in plant control rooms, in motor control centers, near exhaust stacks and in other environmental monitoring applications. The compact, lightweight Atmospheric Corrosion Sensor can be mounted in equipment racks, ventilation ducts or in other desired locations.

Corrosion Coupons - Sensors - Corrosion Under Insulation

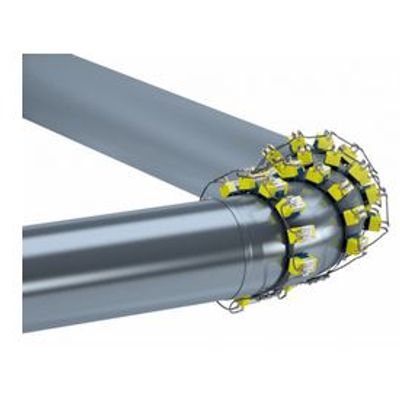

Cosasco - Model CUI - Corrosion Fuse Probe Array Sensor

The Inserted Probe Array Sensor acts as a ‘corrosion fuse’ detector that will provide an indication of corrosion occurring at the pipe surface, at known discrete locations under inuslation. The sensors can be installed on new pipelines field joints, insulated process lines, or on existing insulated pipe or as part of a repair