- Home

- Companies

- CPM Extrusion Group

- Products

CPM Extrusion Group products

Twin Screw Extruders

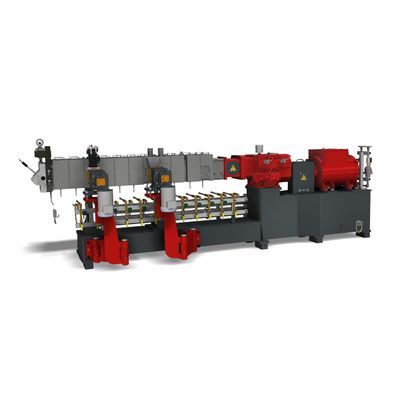

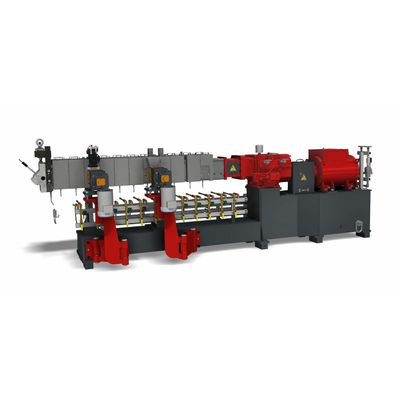

CPM Extrusion - Twin Screw Extruders

CXE series extruders are based on 1.55 diameter ratio with screw diameters ranging from 26mm thru 177mm. CXE process section components (screws, barrels, shafts) are interchangeable with equivalent size ZSK models, thereby eliminating technical risk. CXE series – torque density 11-13 Nm/cm3. CXE-HO series – torque density up to 18 Nm/cm3. Widest portfolio of screw and barrel metallurgies available for the most severe abrasive and corrosive environments. SHO models include options for gearbox monitoring, shaft torque measurement and vibration monitoring systems. Bespoke craftsmanship: all machine specifications configurable to customer requirements. Prototype machinery is our specialty; if you can imagine it, we can build it! Control system platforms designed to customer requirements (e.g. Allen Bradley, Siemens, etc.) including integration with upstream/downstream equipment.