Crenlo Engineered Cabs services

Manufacturing

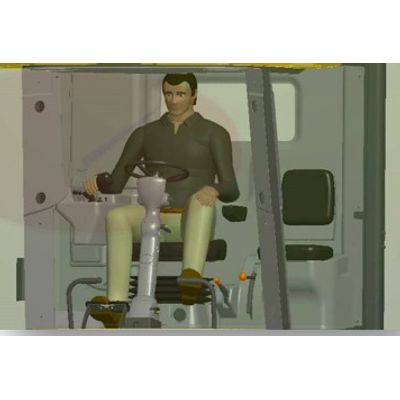

Crenlo Engineered - Virtual and Physical Modeling

We can execute your product’s entire manufacturing needs, from concept to prototype, through pre-production, and then into full production mode. In support of this capability, we maintain a fully self-sufficient model shop for the efficient development of prototype product designs and process development. We also have 3D printing capabilities to rapidly fabricate full scale models in record time. Our prototype and model shop also includes a 200 ton press brake, 5-inch power shear, band saw, drill presses and welding machines. Our highly skilled metal fabrication specialists routinely create pre-production models for evaluation and testing.

Crenlo Engineered - Material Conversion

We utilize the very latest in flexible manufacturing system laser fabrication technologies. Fast and flexible processing of intricate shapes to exacting standards is available in a wide variety of material types and sizes by leveraging our 2500 & 1500 watt laser cell with “lights out” material handling and CNC controlled laser cutters with 1000 watt 4 ft x 8 ft capacity. We convert raw material into close tolerance component parts utilizing the latest processes and tooling technologies. Internal control of piece part fabrication assures the highest degree of product quality and flexibility for our customers.

Crenlo Engineered - Welding Services

Our Process Engineers take great pride in designing and developing the most efficient welding processes for our customer’s products. By designing and building our own production weld fixtures, we can maximize efficiencies during new product start-up phases and assure the highest product quality throughout the life of your program. Superior weld capacity is provided by multiple robotic weld cells, in combination with over 200 wire fed arc weld stations and a variety of resistance welders. Lean manufacturing techniques incorporate “in line” metal finishing processes to maximize manufacturing efficiency.

Crenlo Engineered - Final Cab Assembly

Final cab assembly is accomplished on either a powered floor level wood slat conveyor measuring 5 ft x 324 ft long, or six individual non-powered assembly lines ranging from 41 feet to 165 feet in length. Each line is individually capable of integrating complex electrical and electro-mechanical components into the final cab assembly.

Quality Inspection Services

Our metallurgical lab is equipped to perform the physical testing of tensile, yield, elongation, impact and hardness on incoming raw material. Weld testing and inspection equipment includes both magnetic particle and ultrasonic weld inspection equipment. Dimensional measurement capabilities include a “Fabrivision” optical comparison machine with a 48-inch x 72-inch scan surface; a Virtek QC Laser with a 48-inch scan surface capable of merging four different scans into one report; and three Coordinate Measuring Machines (CMM). A computer assisted Sheffield Portage CMM with 100-inch x 140-inch surface tables and a 72-inch vertical measuring capacity. A Direct Computer Controlled (DCC) Brown & Sharpe Validator CMM with a measuring capacity of 72-inch x 48-inch x 36-inch, and a DCC LK LY90S CMM with a measuring capacity of 118-inch x 62-inch x 98-inch.

Others

Crenlo Engineered - NPI Acceleration

We implement a product development process designed to reduce risks and accelerate product launches to ensure project business case certainty.

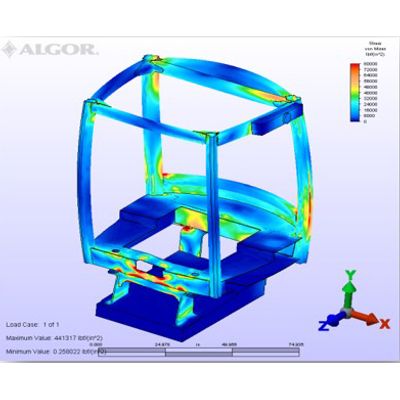

Engineering Services

Crenlo Engineered Cabs designs frequently involve a cross-functional engineering team that includes an application engineer, a design engineer, and manufacturing and quality engineers. You can count on our expert resources and engineering capabilities to support any stage of your new product development project, from concept to production. Our engineers are trained on the latest versions of CAD software, and in most cases, will be able to work in your native file format. Your design can also be tested and certified to several industry standards including ANSI, ASABE, ISO, SAE, and OSHA.

Complex Fabrication Services

Crenlo Engineered Cabs efficiencies and design for manufacturability expertise offers supplementary manufacturing solutions based on combinations of complex metal fabrications and weldments. Working side-by-side in a peer-to-peer relationship with your designers, we accelerate new product development with custom products designed to exceed your expectations while meeting your requirements and specifications.