- Home

- Companies

- Crest Pumps Ltd.

- Products

Crest Pumps Ltd. products

Mag Drive Pumps

Crest Pumps - Ultra Efficient Magnetic Drive Plastic Pump

Runs cheaper, lasts longer, and saves you more. Chemical Resistant Pumps The AVF-X series is one of the first plastic magnetic drive pumps to meet the highest European pump efficiency standards on the market (Commission Regulation (EU) No. 547/2012 with an MEI ≥0.7). This means you can rest assured knowing you are using one of the most energy efficient pumps available and benefiting from exceptional energy savings in your production processes whilst reducing your overall carbon footprint.

Crest Pumps - Superior Efficiency Canned Motor Mag Drive Pump

The AVF-C plastic canned motor mag drive pump is built to save you energy - with the highest motor efficiency (IE5 & GB1 equivalent), highest pump efficiency (Minimum Efficiency Index, MEI >0.7), and variable frequency drive meaning the smallest carbon emissions chemical pump you will ever own.

Mech Sealed Pumps

Crest Pumps - ISO2858 Thermoplastic Mechanically Sealed Centrifugal Pumps

The new corrosion resistant EOV centrifugal pump range gives you up to 15% increase in performance whilst consuming up to 20% less power compared to the previous industry trusted ECC range. This huge improvement in efficiency means you will reduce your energy consumption costs and reduce your risk of unplanned downtime.

Crest Pumps - Metallic ISO2858 End Suction Process Pumps

Built to a heavy duty standard in a stainless steel construction, and built to ISO2858 and EN25199 which helps to ensure up to 100,000 operational hours. Minimal maintenance and high efficiency reduces downtime. This range is available with open/closed or vortex impeller options. The RD-RG-RC-RB ranges can handle aggressive and inorganic liquids in the chemical & petrochemical industries. They are also used in sea water desalination plants, absorption equipment in environmental engineering, power stations, steel industry and hot water distribution.

Vertical Immersible Pumps

Crest Pumps - Vertical Sealless Plastic Pumps

The Surge range replaces the previous VSL range of vertical immersible corrosion resistant pumps, built upon the tried and tested rugged reliability of the VSL but with developments in the casing and impeller design, generating up to 30% greater performance whilst consuming less power. Designed and manufactured in the UK with the simplicity of 5 models sharing as many common components as possible, it enables quicker lead times and even more competitive pricing. All Surge pumps feature a standard column length of 400mm and are offered with optional extras including suction extensions, non-return valves, strainers and level control switches which are all readily available.

Crest Pumps - Cantilever Corrosion Resistant Sump Pump

The CSS range of vertical plastic pumps have been perfected over 40 years to combat harsh and corrosive chemicals making the CSS range ideal for applications such as sump emptying, recirculation, effluent treatment and fume scrubbers. Every plastic vertical pump in our range is designed and manufactured in the UK so we can tailor the pump to your exact requirements – whether that be a particular column length, mounting plate shape or outlet position. Usually with very little difference in price or lead time compared to a standard pump. The CSS range is available in polypropylene or PVDF for the ultimate corrosion resistance to harsh and acidic applications. O-rings are available in Viton, EPDM or Kalrez.

Air Operated Diaphragm Pumps - Boxer Range

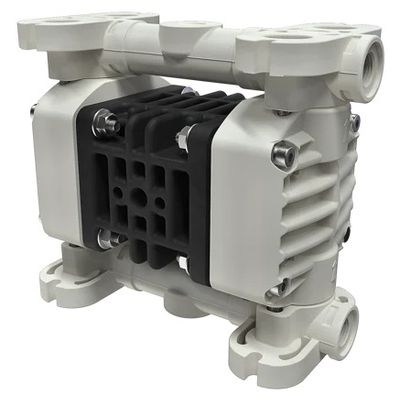

Crest Pumps Boxer - Air Operated Double Diaphragm Pumps

The Boxer range are air-operated double diaphragm volumetric pumps, ATEX - IECEx certified, constructed in Polypropylene or PVDF in the plastic version or in aluminum or AISI 316 L for the metal versions. Boxer pumps are ideal for pumping liquids with high apparent viscosity, even if containing suspended solids. The Boxer series of pumps are self-priming, have dry run operation, and adjustable operating speed making them extremely versatile and suitable for continuous use. The vast range of materials available for the parts in contact with the fluid, such as pump casings and manifolds, diaphragms, balls, ball seats and o-rings, makes them compatible with any type of fluid present on the market.

Air Operated Diaphragm Pumps - FDA Stainless Steel AODD Pumps

Crest Pumps Foodboxer - Air Operated Double Diaphragm Pumps

The Foodboxer range are positive displacement pumps operated by compressed air, with double diaphragm. They are suitable for handling fluids with high apparent viscosity and demanding applications, even in the presence of suspended solid parts. The Foodboxers are extremely versatile pumps, they are self priming with dry operation and have an adjustable operating speed. ATEX - IECEx certified, FDA Complient and built in AISI316 / AISI316 L.

Air Operated Diaphragm Pumps

Crest Pumps - Air Operated Diaphragm Pumps

A real must for any pneumatic pump in those applications where a smooth regular fluid output is required. These are also available as ATEX-certified, making them suitable for potentially explosive environments. Their self regulating characteristic makes them extremely user friendly, with top notch effectiveness in protecting your pipings and machinery from water hammers generated by a diaphragm pump. The ample choice in materials for castings and diaphragms in an Equaflux dampener grants the same chemical compatibility of any accompanying pump. They have no troubles with viscosities and solids in the range of their pneumatic pumps counterparts. The Equaflux range are also availble as ATEX-certified, making them suitable for potentially explosive environments.

Air Operated Diaphragm Pumps - Aisiboxer Range

Crest Pumps Aisiboxer - FDA Double Diaphragm Volumetric Pumps

The AISIBOXER Line of volumetric pumps driven by compressed air, with double diaphragm are MOCA – ATEX – FDA certified. They are built in mechanically polished AISI 316 L with a surface finish of less than 0.8 μm. The pumps are suitable for moving fluids in sectors such as the food and beverage and cosmetic industries. They constitute an optimal solution for the transport of liquids and fluids with high apparent viscosity, even in the presence of suspended solid parts.