CRIFI. S.r.l. products

Machines - Impact Crushers Machines

Crifi - Secondary Crusher

Mills type MP are particularly fit for secondary crushing of semi-hard materials and, by employing special anti-abrasive chromium-molybdenum alloys, they can be used for hard materials too. Machines are manufactured on the basis of simplicity and hardness; all wearing parts have been designed in order to make them very easy to change. The presence of hydraulic pistons enables an optimal adjustment of the output product size according to hammers wear. Secondary mills type MP produce granulates with an excellent polyhedral quality and with low energy consumption.

Crifi - Primary Crusher

Primary mills type CMP are particularly fit for crushing semi-hard materials and, by employing special anti-abrasive chromium-molybdenum alloys, they can be used for hard materials too. Machines are manufactured on the basis of simplicity and hardness; all wearing parts have been designed in order to make them very easy to change. The presence of hydraulic pistons enables an optimal adjustment of the output product size according to hammers wear. Primary mills type CMP produce highly cubic materials with low filler production and low energy consumption.

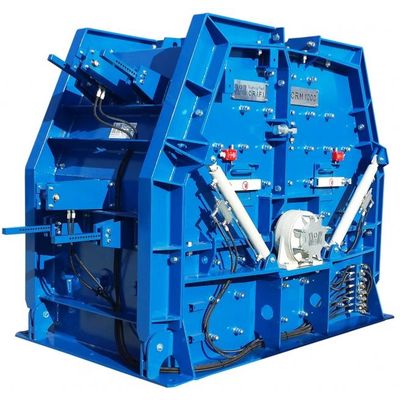

Crifi - Reversible Tertiary Impact Crusher

The reversible impact crusher mod. CRM have been studied making the most of all the technical knowledge on impact crushing. Essential prerogative to guarantee maximum yield, lower consumption and better quality produced.

Crifi - Reversible Tertiary Crusher

Crusher, mod. CRMT is a machine for the tertiary crushing of very compacts materials and abrasives too, thank to the particular alloys adopted for the materials and the inner armours. The materials broking happens through the self - crushing and the high speed of the rotor allows the breaking of small material.

Machines - Jaw Crusher

Crifi - Jaw Crusher

Jaw crushers BRC are intermittent machineries, used during the primary demolition, whose grinded action, is executed by a vertical, fixed jaw grip and by other frontally moving jaw grip; the interchange of coming and separation moving jaw grip’s movements, causes the demolition of the material, that firstly falls between the two organs during the removal phase and consequently it is reduced by their successive approach.

Machines - Washing and Cleaning

Crifi - Grizzly Vibrating Screen

Grizzly vibrating screens of VSG series have been studied for the primary screening of both alluvial materials and quarry tout - venant ones. They have been installed previously in a primary crushing machine. Vibrating screens GRIZZLY of VSG series, because of their specific use, are overstated in all the structures. The superior screening level can be equipped by steel bars as a stair disposition or by a perforated plate.

Crifi - Bucket Reclaimers

Used for sand reclamation and washing. They can be placed either after a screening machine with wash system or separately for the washing of natural sand mixed with dry impurities. Our reclaimers almost completely avoid fine material outlet as they are provided with huge tubs; therefore sand production in increased. They are also equipped with an adjustable skimmer which can regulate fine material outlet.

Crifi - Trommel Rotating Screen

VTSM rotating screens, also called bar screen, are studied in a specific way for the cleaning of the material. Their scope is very broad, from the recycling of materials coming from the crushing to the waste industry. The screen cylinder is constructed with big thickness plats for supporting the weight of the rock inside the machine.

Crifi - Wobbler Feeder

The disc machine is very robust capable of working under difficult conditions, ideal for supporting material of large pieces and cuttings of clay material and with high humidity.

Crifi - Rotating Screen

Rotating screens VTS are used for the cleaning and selection of fluvial not too much dirty materials. These machines are assembled with sturdy structures. Inside the machines the rolled plate vane allows the advance of the material; the armour on the entrance of the material and the perforated plates, are installed by means of bolts that help easily their substitution in case of wear. the transmission occurs by the chain, the pinion is mounted on the reducer that in turn is set in motion by an electric motor and a belt.