Curran International services

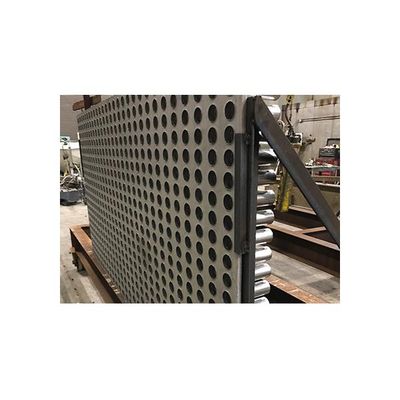

Heat Exchanger Coating

Exchanger Resortation - Tube ID Coating

Evolution of Condenser Tube Coating: Exchanger restoration using tube ID coating has its origins in a power plant project in the early 1990s. Tube ID coating was successfully used to mitigate unexpected corrosion of a condenser bundle; the restoration was a cost-effective option to a bundle retube and returned generation capacity. Since that project Curran has applied thin film tube ID coating for condenser and heat exchanger tube repair at industrial plants across the globe.

Tube Liners

Hydraulically Expanded Alloy Liners

Curran installs full length exchanger tube liners to restore corroded tubes to service. Using a corrosion resistant alloy, corroded fin fan air cooler tubes can be returned to service using full length liners. Condenser tube liners can be installed on any exchanger that can be retubed in place, and should be considered as an option to a partial retube, or restoring corroded tubes in service. Using a hydraulic pump, the alloy liner makes intimate contact for a full length tube-in-tube repair.

Tube End Ferrules and Sleeves

Curran can provide exchanger and condenser tube repairs using alloy tube ferrules made of a corrosion resistant alloy. Hydraulic expansion of ferrules ensures uniform expansion, resulting in long term condenser restoration. Curran can install ferrules or sleeves to inhibit fluid velocity erosion and turbulent condensing gases that lead to localized wear. Ferrules provide improved wear resistance so that the tube end and its sealing integrity with tubesheet sheet is maintained.

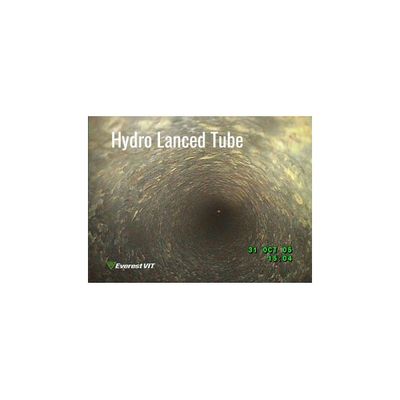

Tube Cleaning

Curran - Exchanger Tube Cleaning

Curran tube ID dry grit blast cleaning method has elevated expectations of tube cleanliness for Non-Destructive Evaluation (NDE). Never again compromise PEI data with poor inspections as a result of “dirty tubes.” Using high velocity, high pressure air, Curran is expert at scouring tenacious scale and deposits from tube substrate and pits. Curran tube ID cleaning has facilitated high integrity NDE data acquisition of air coolers, SRU exchangers, and surface condensers. Curran crews are expert at performing work in-situ, during turnarounds and equipment maintenance outages, providing vacuum containment to eliminate nuisance dust, and capture all waste debris.