Custom Fabricating & Repair, Inc. products

CFR - Dryers

20 different Dryers sold since 2009: NFDM (non-fat dry milk), MPC (milk protein concentrate), WPC (whey protein concentrate), WPI (whey protein isolate), SMP (skim milk powder), Buttermilk, Cheese Powder, Whole milk, Dairy blends, Infant Formula.

Cheese Equipment

CheddarMaster - Cheese Belt System

CFR’s team has worked extensively to design and develop the Cheddarmaster Belt System. CFR’s complete system offers proper whey drainage, matting, milling, uniform salting, and sufficient residence time to produce quality cheese. Our unique salt delivery system offers the optimal salt retention.

CFR - Block Forming Towers

CFR Block Forming Towers were designed and developed to provide superior process, handling and packaging solutions for American, Italian or Hispanic Cheese Producers. Our commitment to innovation and excellence has driven us to develop an exceptional system that offers quality block formation, precise cutting, optimal whey collection, full automation and clean-ability, while sustaining the customers desired cheese integrity and different makes. Offering the delivery of standard or custom designed process solutions.

CFR - Cheese Vats

CFR’s offers the High Solids Cheese Vat designed specifically for modern cheese making methods and increased throughput from your cheese plant. The HSCV Cheese Vat addresses key cheese processor concerns for Yield, Cleanability of the Vat, and Maintenance. CFR can provide turn-key solutions including engineering, equipment fabrication, automation, and installation at the best value in the industry. CFR will provide timely and accurate budgetary pricing for major projects. This allows our customers to evaluate expansion opportunities at a very early stage. CFR has a dedicated Cheese Group assigned to the development and support of greenfield and brownfield cheese plant opportunities. This group includes engineering and cheese technologist.

CFR - Block Crumbler

CFR’s Block Crumbler offers the cheese producer the opportunity to crumble either 40 lb. or 60lb. Cheese Blocks, which are conveyed from the block forming towers. The crumbled cheese can then be blown by CFR’s sanitary airlock valve and blower system over to a fill station cyclone to fill either 640lb. Block Containers or 500lb. Barrels to further continue the cheese packaging process. The Block Crumbler has been designed and developed to provide an even and size consistent crumbling affect, offering homogenous crumbled pieces, which facilitates in the reknit process. The Block Crumbler is also designed with a sanitary interior trough, providing efficient product movement during production, as well as sanitary clean-ability during CIP. Today’s current model is built with leading-edge automation, built with structural upgrades, and is engineered with optimal features providing a smooth transition of product.

CFR - Collating System

CFR’s collating system is used by bulk cheese makers producing 40lb. Blocks. The collator is used in the conversion process of collecting either sixteen (16) 40 lb. Blocks or (12) 55lb. Blocks from the block forming towers and collating them into a single 640 lb. Block. This packaging system offers the cheese producer the option to produce and package either 40lb. Blocks or 640 lb. Blocks.

CFR - Curd Distributor

CFR’s Curd Distributor provides an even flow and consistent distribution of curd supply to each block former as required to maintain required process capacity. Our units are custom built per process specifications; therefore we can also provide a unit to be integrated into an existing system matching all plant specs and capacity requirements.

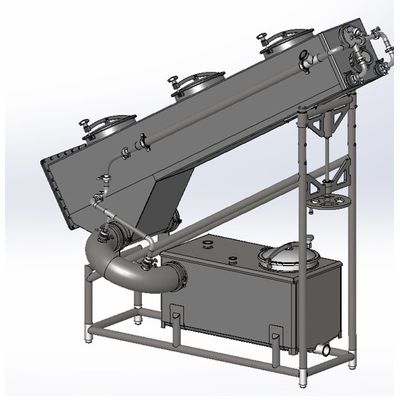

CFR - Fines Saver

CFR Fines Saver Features: No Moving Parts, Customized Wedge Wire Screen Openings, Variable Whey Removal Percentage, Fully CIP’able, Adjustable Flow Angle, Up to 100,000 Pounds per Hour Capacity, Used as a Fines Saver or a Pre-Draw Screen.

CFR - Auto Unloader

CFR’s Auto Unloader is used to transfer 640lb. Blocks off of the dollies from the automated track system to an unload conveyor or staging area for pickup by forklift. We will configure to your meet your specific needs and maximize efficiency.