- Home

- Companies

- CV Technology, Inc.

- Products

CV Technology, Inc. products

Explosion Vents

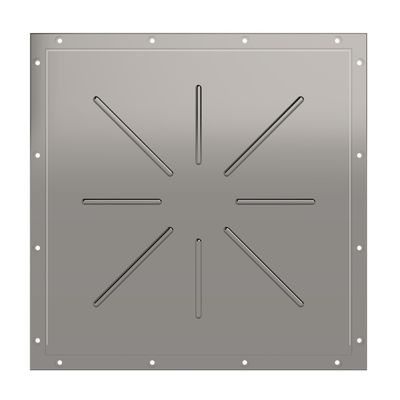

Model TLFG - Explosion Vents

A versatile explosion vent design, the TLFG is specially designed to handle any application or process. The composite, domed vent construction provides high vacuum resistance and high-pressure cycling resistance. They can also be paired with a flameless vent to provide indoor venting or ducted to a safe area through a duct. The TLFG explosion vent is a domed composite explosion vent. Three-layer comprise the explosion vent with 304 stainless steel product contact and PTFE sealant layer. Features include an integrated burst indicator and a variety of gasket materials.

Model SLFG - Explosion Vent

An economical explosion vent, the SLFG provides the most cost effective solution for explosion venting. An integrated vent frame and gasket allows for simple, quick installation and replacement. Ideal for applications with lower pressure cycling or atmospheric pressures the SLFG can be applied to dust collectors, storage vessels, or conveyors. Features include optional burst indicator and relay module.

Model TLST - Explosion Vent

The ultimate sanitary design, the TLST explosion vent is USDA Dairy certified model for use any food or dairy applications. The composite design can be paired with a flameless vent to provide indoor venting or ducted to a safe area through a duct. The TLST explosion vent is a domed composite explosion vent. Three layers comprise the explosion vent with polished 316 stainless steel product contact and PTFE sealant layer. Features include an integrated burst indicator.

Flameless Explosion Venting

Interceptor - Model QR - NFPA Compliant and FM Approved Flameless Venting Device

The Interceptor-QR is a NFPA compliant and FM Approved flameless venting device. Often referred to as a quench tube, round style flameless vents offer the advantage of optimum venting efficiency to handle all applications. Dusts approved for the Interceptor-QR include organic material, melting, fibrous, and light metal dusts.

Interceptor - Model LT - NFPA Compliant Flameless Venting Device

The Interceptor-LT is a NFPA compliant flameless venting device. Designed as an economical solution for flameless venting the I-LT features a painted carbon steel frame with stainless steel mesh insert. The rectangular cross-section allows for maximum vent area and sleek installation.

Interceptor - Model EV - NFPA Compliant Flameless Venting Device

The Interceptor-EV is a NFPA compliant flameless venting device. Specially designed with a slim, elongated profile this flameless vent is ideal for bucket elevators and conveyors where installation locations are limited. The lighter frame is painted carbon steel with a stainless steel mesh insert. The compact design allows for easier handling and installation. Comprised of both the flame arrestor and explosion vent the Interceptor-EV can be rearmed in the field. The standard TLFG model explosion vent allows this flameless vent to be used on variety of difficult applications including bucket elevators, conveyors, and small vessels.

Active Dry Chemical Suppression

Interceptor - Model HRD - High Rate Discharge Suppression

The Interceptor®-HRD bottles are NFPA compliant High Rate Discharge suppression bottles. These suppression bottles contain pressurized Nitrogen and dry chemical suppressant to suppress a deflagration as it develops. A variety of sizes and nozzle designs, including USDA certified options, allow the HRD suppression bottles to be used on any application.

Explosion Isolation

Interceptor - Model QV - Explosion Isolation Device

The Interceptor-QV is a new patented explosion isolation device built with the principles of flameless venting. A stainless steel mesh cartridge in the center of the device works to stop a deflagration. If a deflagration propagates through the clean return line it will make contact with the mesh cartridge. The cartridge removes energy from the flame front of the deflagration as it passes through the torturous path of the mesh, forcing the flame to transfer its energy to the high surface area of the mesh, thereby quenching the deflagration and not allowing any flame to pass beyond the Interceptor-QV.

Interceptor - Model VE - Explosion Isolation Pinch Valve

The Interceptor®-VE® is a NFPA 69 compliant isolation pinch valve. The Interceptor®-VE® valve is normally open. Upon receiving a signal from either a pressure responder or an optical sensor the Interceptor®-VE® controller is designed to immediately signal the Interceptor®-VE® valve. The Interceptor®-VE® valve will close in milliseconds to prevent the passage of hot particles, glowing embers, flame, or pressure from continuing to flow through the pipe. The medium of actuation is plant compressed air stored in a tank on the valve to ensure the fastest response possible under any plant conditions.

Interceptor - Model SG - Explosion Isolation Slide Gate Valve

The Interceptor-SG explosion isolation valve is designed to prevent explosion propagation from one vessel to another through interconnected piping. The explosion isolation slide gate is a compliant solution for both NFPA 69 and FM 7-76. The isolation valve is a normally open device, however upon receiving a signal from a pressure detector, the Interceptor-SG explosion isolation valve is designed to rapidly close. The medium for actuation is plant-compressed air stored in a tank on the valve to ensure the fastest response possible under any plant conditions. The valve closure principle is a slide gate that closes when a high speed solenoid valve changes state releasing the compressed air.