Daxtro Swiss International Engineering Company SARL products

Daxtro Water Management Solutions

Daxtro - Pre-Separation Wastewater Systems

Pre-separation systems are indispensable in any kind of waste water treatment, because it helps to ensure optimal performance for the whole plant, allowing the solids retention (depend of the cases, also sand) that may become damaged the operation for electromechanical equipment installed in the next stages. Therefore, it system will drastically reduce the preventive and/or corrective maintenance operation, increasing the lifetime of the plant.

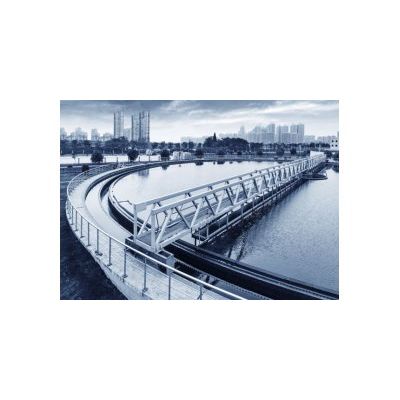

Daxtrosed - Primary Clarifier System

The primary clarifiers line DAXTROSED are known for High Capacity & High Efficiency, basically is an improvement of traditional circular clarifiers, adding a touch of Daxtro engineering. It causes a 45% improvement in efficiency compared to its “traditional” counterpart. Our systems come with real-time control.

Daxtroflot - Flotation Systems

Flotation systems line DAXTROFLOT usually is applied instead of primary clarifiers (in municipal applications) because presents advantages of time and space, besides are applied in almost all industrial fields in which are required an effective separation of Total Suspended Solids (TSS) (greater than 95%), fats, oils and other parameters. It is an attractive solution because requires a minimal amount of space compared to another types of systems, this is due to the treatment time depending of the application may vary from 2 to 7 minutes instead of the conventional systems that may require 10 to 12 hours (under normal conditions).