De Dietrich Process Systems products

Filter & Filter/Dryer

Whether in the chemical, pharmaceutical or food industry, Rosenmund Filter and Filter/Dryers prove themselves through a very high efficiency in washing and isolating solids, even in the most difficult production processes. The high performance Rosenmund Filters can also be converted to Filter/Dryers simply and quickly, by the addition of upgraded features.

Double Conical Dryer

The glass lined double conical dryer type SR is a device that was designed for drying easily flowing products. The rotation of the double cone allows the product to be mixed without an internal agitator.

Pan Dryers

The pan dryer is based on the well established and proven Filter/Dryer technology; Here, however, the porous filter bottom is replaced with a heated flat bottom.

Spherical Dryers

The trend setting spherical dryer range with top or bottom drive is the latest development of the proven Rosenmund dryers that achieve the highest performance standards. A versatile solution for drying, mixing and granulating.

Reaction - Glass-Lined Reactor

De Dietrich - Pharma Reactor

A wide range from 63 l up to 630 l. Optimization of the thermal transfer and the mixing performances (OptiMix®). Glass-lined flat cover with excellent surface finish and pad nozzles. Polished 316L Stainless Steel sheathing on drive and motor. CIP validation. Successful test results.

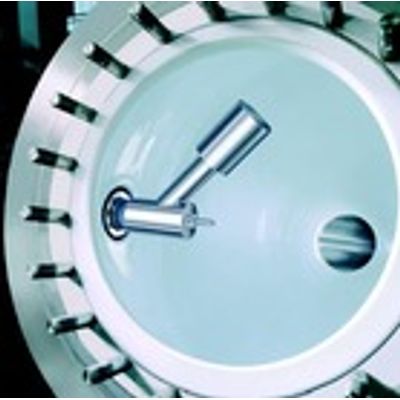

De Dietrich OptiMix - Glass-Lined Reactor

This patented design enhances heat transfer, solids suspension and distribution, gas dispersion, gas flow rates and mass transfer. The OptiMix glass-lined reactor`s performances are based on the integration of three baffles onto the vessel wall. This leads to a notable improvement in the capacity of the mixture and in heat transfer compared to the standard DIN series. The result is that all the nozzles remain free for the process. This arrangement considerably improves the hydrodynamics by using an optimized baffling effect. The profile of the paddles prevents the accumulation of crystals in the event of crystallization. This design satisfies two of industry`s primary requirements: optimal process efficiency and improved cleanability of the reactor, as well as a reduction of the amount of dead zones which generally occurs with a standard, nozzle-mounted baffle.

Reaction

De Dietrich - Flextech Reactor

The technology and the experience of De Dietrich Process Systems for your alloy and stainless steel reactor. A complete range from 63 l to 10,000 l. Geometry according to DIN 28136-1. Temperature sensor integrated in the wall. Integration of all mechanical aspects. Process intensification: Our expertise at your service, Efficient mixing technology, Improved heat transfer. Global certification: PED, ATEX, Machinery Directives, F.A.T. with dynamic tests. Optimization of cleaning with guarantee of results.