Delta Cooling Towers, Inc products

Cooling Towers

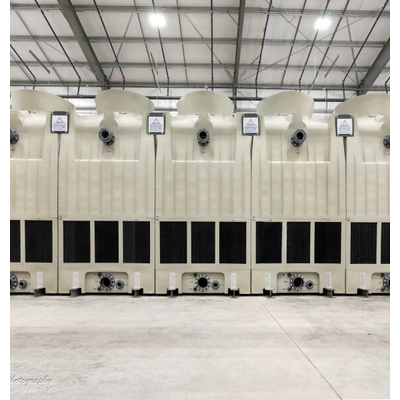

Delta - Model TMX Series - Induced Draft Cooling Tower

Our new factory, equipped with the largest molding equipment of its kind in North America, is now producing the new TMX Series Cooling Tower! The tower sump is molded from HDPE in a single, continuous piece over 20 feet long, eliminating joints, seams, or welds that are prone to leaks and maintenance issues.

Delta - Model TM Series - Induced Draft Cooling Tower

Our long history of innovation in the industry coupled with our recent product upgrades makes Delta the technology-leading cooling tower supplier in the United States. Regardless of your need, Delta provides innovative cooling tower designs that last longer, save on costs, and eliminate downtime. All of our products, including the TM Series Induced Draft Tower, are suitable for a variety of applications. The TM Series are available in standard tonnage such as 250 tons, 300 tons, 400 tons, 500 tons, 600 tons, 750 tons, 1000 ton and beyond. Visit the product page for specific capacity measurements.

Delta - Model Paragon Series - Induced Draft Coolilng Tower

Choose Delta’s Acclaimed PARAGON® Induced Draft Tower. Since we introduced the PARAGON® Induced Draft Tower nearly forty years ago, it has been one of the most in-demand cooling towers on the market. Learn more about this innovative product that has stood the test of time.

Delta - Model Pioneer Series - Forced Draft Cooling Tower

If you’re researching highly efficient and environmentally friendly cooling towers, then look no further than Delta’s Pioneer Forced Draft Cooling Tower. Request a quote today! Experience Efficiency & Affordability with Delta’s Pioneer Forced Draft Towers. Delta’s Pioneer® forced draft, counter flow design comes in single module capacities and in a range of cooling tower tonnage--from 10 to 100 cooling tons. Make the change to Delta Cooling Towers today.

Packaged Cooling Systems

Delta - Closed-Circuit Cooling Systems

Delta Closed-Loop Cooling Water Systems are designed to keep your system working when you need it most. Each tower includes a seamless exterior shell. We mold the entire casing of the cooling tower as one piece so there are no joints or seams to require maintenance or develop leaks. The durable shell is made of engineered plastic (HDPE) and is entirely corrosion-proof. This innovative feature minimizes your maintenance costs over time. It also allows our water cooling towers to handle the toughest water cooling jobs in any climate while offering an industry-leading 20-year warranty.

Delta - Evaporative System with Pumps & Controls

Delta’s ES (Evaporative System) consists of a Cooling Tower with Pump Skid Station. Delta’s ES (Evaporative System) Skid includes: Pump(s), Control Panel, Pre-Wiring of skid components to Panel, and pre-piping of necessary components. All components skid mounted on one common skid. A Plate and Frame Heat Exchanger is added when a closed loop on the process side of the Heat Exchanger is required. Other options/accessories are available. The advantages of this system are it is the most energy efficient (lowest operating cost) and lower first cost.

Air Strippers, Degassifiers & Odor Control Scrubbers

Delta - Model Vanguard - Air Strippers & Degassifiers

Vanguard® Air Strippers are custom designed up to 15 foot diameter and 4000 GPM per column. Delta has provided innovative and economical air stripping solutions to more than 500 installations since our first Air Stripping Tower was delivered almost 40 years ago in 1981. Today, air stripping continues to be the preferred water remediation technology for removal of organic solvents, chlorinated hydrocarbons, fuel/gasoline hydrocarbons, degreasers, and certain other volatile organic chemicals (VOCs), because it is the most cost effective when considering Initial, Operating, and Maintenance costs. Delta’s broad knowledge and vast experience has enabled the company to continually develop and refine the Delta Vanguard® line of standard air stripping towers. Delta’s Vanguard Air Stripper Systems are preferred for routine installations as well as for many applications with difficult to strip chemical compounds.

Delta - Model Vanguard - Scrubbers & Odor Control System

Vanguard Scrubbers and Odor Control Systems are custom designed for air flow rates of 1,000cfm to 75,000cfm per column. Wet Scrubbing is the industry standard for the treatment of odors prior to releasing the air stream to atmosphere, because it is the most cost effective when considering initial operating and maintenance costs.

Delta - Chemical Cleaning System

The Chemical Cleaning System is a pre-engineered and shop assembled clean-in-place system, Air Strippers and Degassifiers. The automated system utilizes a powerful acid solution for the most efficient cleaning cycle possible. The automated system utilizes a powerful acid solution for the most efficient cleaning cycle possible. This cleaning cycle returns the packed tower to its original condition increasing the tower’s performance and saving blower energy by reducing the packed bed pressure drop. The system is effective in removing Iron and Manganese fouling as well as Calcium Scaling.

Delta - Box Style Aerator

The Delta AS line of Box Style Aeration Towers are a low cost alternative to Packed Tower Air Strippers. They are available in Aluminum, Stainless Steel, and Fiberglass and can be sized for flow rates from 100gpm to 3,000gpm.