- Home

- Companies

- Dena Nano Ltd

- Products

Dena Nano Ltd products

Tyre Recycling Technology

Dena - Model 62 - 32HTE - Shredder

Whole tires will be fed to the Dena 62-32HTE tire shredder. This unit will reduce the whole passenger tires to a variable size strip. The shredded tire strips will average 2”-4” wide x 6”-10” long with occasional pieces up to 12”-16” long. Returning the shreds back to the shredder allows the shredder to produce a consistently sized chip averaging 50-150mm in size. This increases production and reduces wear for the Grizzly.

Grizzly - Model 50 - Shredder

Primary tire chips are then fed to the Granutech Model 50 Grizzly. This unit is an intermediate-speed grinder that utilizes an internal screen. The primary tire shreds are reduced to a minus 3/8” material in the Grizzly. This reduction will allow ferrous metal from the bead and tread area to be liberated, and then magnetically separated, providing a material that is up to 98% metal-free for ease of further processing. An aspiration system evacuates airborne particulate produced from dust and fiber. Material at this stage can be marketed as high quality low-steel tire derived fuel (TDF) for a wide variety of combustion applications. Further steel separation allows production of steel free rubber.

Dena - Model G - 4 - Refiner Mill

The near steel-free, low fiber content granules are fed to the fine grind mill for grinding to ultra-fine powder. The Refiner Mill reduces material to the desired end product of 30 mesh and smaller. Changing the screens after Mill allows the client to produce virtually any size product a client will request. Further metal and fiber separation assure the crumb rubber is the cleanest available material.

Dena - Automated Material Dispensing System

Materials of specific sizes can be automatically dispensed into a variety of storing or shipping containers. Material is electronically weighed and

mechanically shaken to ensure consistent and accurate weight and density.

Dena Nano - Paint System

Dena Nanometric processing Systems are designed to utilise several different func-tions within each production System; de-agglomeration, particle size reduction and homogenising to process the particles suspended in paint & coating down to Nano-metric scale. Nano metrics is the process of reducing particle size to Nano scale; our machine can reduce particle size upto 50 Nanometers. We have demonstrated time to time that our technology improves quality, consistency, coverage, economics and there-by the profitability for our clients.

Nanolutions

Nano - Emission Reduction Technology

Dena Nano Ltd works from its drive to pay back the environment and uses the phrase “Green from Green” to describe the ability to put our technology into action to aid with reducing harmful emissions.

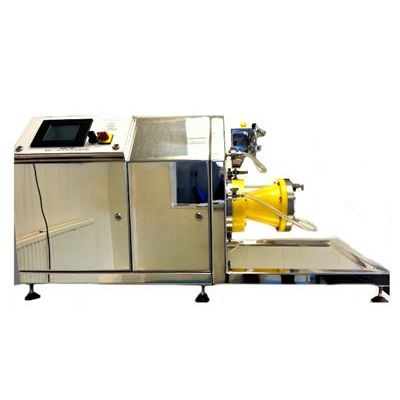

Dena - Nanometric Paint & Coating Processing System

Dena Nanometric processing Systems are designed to utilise several different functions within each production System; de-agglomeration, particle size reduction and homogenising to process the particles suspended in paint & coating down to Nanometric scale. Nano metrics is the process of reducing particle size to Nano scale; our machine can reduce particle size upto 50 Nanometers. We have demonstrated time to time that our technology improves quality, consistency, coverage, economics and thereby the profitability for our clients.