Design Tool, Inc. products

Handheld Automatic Screwdrivers

DTI - Automatic Screw Feeding and Screwdriver Inline Screwdrivers

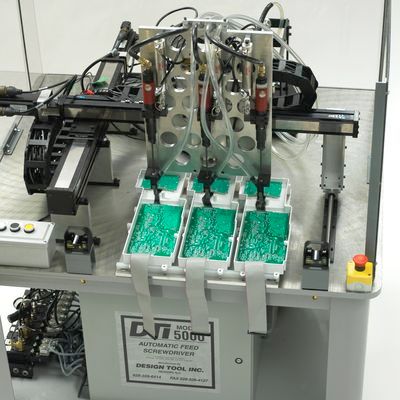

The DTI 5000 automatic fastening inline screwdriver systems are available in several different configurations, including standard, rigid, retracting barrel and counterbore tip designs. These machines are custom designed for vertical applications with the nose piece jaws fitting the customer’s part. The inline screwdriver assemblies can be designed for a wide range of applications and fastener types including screws, bolts, nuts, pins, or nails. The standard screw feeder system cycles quickly delivering screws in less than one second in many applications. The rigid units maintain contact between the bit and the fastener in order to locate the screw in predrilled or misaligned holes. The retracting barrel feature is offered in both rigid and non-rigid designs.

DTI - Automatic Screw Feeding and Pistol Grip Screwdriver Systems

DTI 5000 automatic screw feeding and pistol grip screwdriver systems are available in several different configurations, including standard, rigid, and retracting barrel designs. These machines are custom designed for vertical and horizontal applications with the nose piece jaws fitting the customer’s part. The pistol screwdriver assemblies can be designed for a wide range of applications and fastener types including screws, bolts, nuts, pins, or nails. The standard screw feeder systems cycle quickly delivering screws in less than one second in many applications. The rigid units maintain contact between the bit and the fastener in order to locate the screw in predrilled or misaligned holes. The retracting barrel feature is offered in both rigid and non-rigid designs. This system retracts the barrel fully when the driver starts, so that the driver components do not contact the work surface when the screw is driven.

DTI - Automatic Screw Feeding and Rigid Screwdriving Systems

The DTI 5000 Rigid Automatic screwdriving systems are designed to hold the fastener securely in the barrel and collet assembly keeping the bit in contact with the fastener. This system is ideal for applications where a fastener is sticking out of the collet assembly and is inserted through multiple components into a pre-threaded or pre-drilled hole helping the operator to guide it into the fastener location. The rigid feature allows the fastener to locate the hole without being pushed back into the barrel assembly and is used in tight clearance applications.

Multiple Spindle Fixtured Systems and Robotics

DTI - X-Y Robotic Screw Feeder Systems

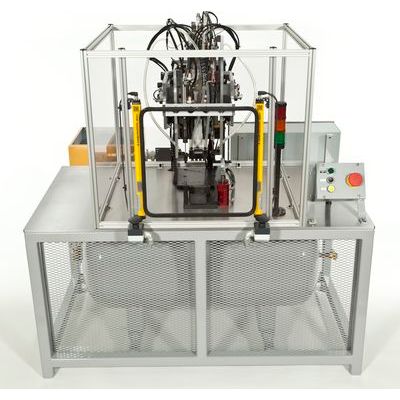

Design Tool Inc. offers complete, turnkey X-Y Cartesian or SCARA robotic systems to assemble components as a standalone station or fully integrated into the assembly line process. The DTI X-Y systems can be designed with single or multiple spindle screwdrivers, and can accommodate almost any fastener pattern. Using proven and robust linear actuators or SCARA robots, these machines offer higher volume productivity while reducing assembly cost. High actuator speeds decrease travel time which results in a reduction of overall cycle time. The ability to utilize multiple spindle screwdrivers allows the simultaneously assembly of several components, which frees up the operator to perform additional assembly tasks.

DTI - Automatic Screw Feeding and Screwdriving Fixtured Systems

Design Tool Inc. offers turnkey fixtured systems to assemble components as a standalone station or fully integrated into the assembly line process. The DTI fixtured screwdriving systems can be designed with single or multiple screwdriver spindles in fixed locations to accommodate a variety of fastener patterns. Using proven and robust vertical thrusters, these machines offer higher volume productivity while reducing assembly cost. Linear movement using linear bearings and cylinders or actuators is also available when required to meet a particular fastener pattern. The DTI 5000 multi-feed patented bowl feeder systems can deliver the fasteners to multiple drivers from a single bowl decreasing cycle time and improve productivity.

Fixtured Components, Machine Builders & Integrators

DTI - Screwdriver Platen Assemblies

Design Tool Inc. offers Screwdriver Platen Assemblies with feed systems to machine builders or manufacturers for integration into assembly machines or robotic cells. DTI can supply single or multiple spindle platens depending upon the application, with a corresponding feed system to feed the required number of screwdrivers. The platens feature linear bearings matched to the driver selection for torque and weight. The platen assemblies can be built on both pneumatic and DC Electric drivers for added versatility. Other options include drive-to-depth to control the seating depth of the fastener, and vertical thrusters for raising and lowering the platen assembly to the work.

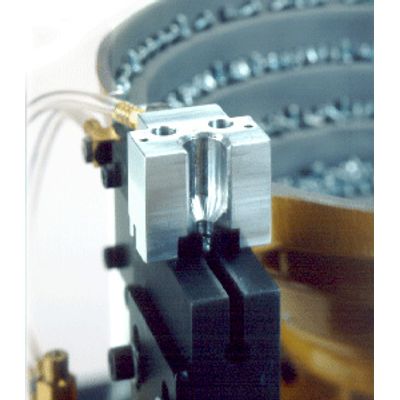

DTI - Multiple Spindle Screwdriving Components

Design Tool Inc. offers multiple spindle screwdriving systems that machine builders or manufacturers can integrate into their assembly equipment. These multiple spindle systems are normally mounted on platen assemblies, and are fed by our single exit or dual exit feeding systems combined with our multi-feeding systems to allow the screwdriver assemblies to be fed from one bowl feeder. This feature maximizes value and minimizes space requirements for the bowl feeding system. Often, an auxiliary feed hopper is used to further increase screw capacity for longer run times between refilling.

Automatic Fastener Presenting

DTI - Automatic Screw Presenting Systems

Design Tool Inc. offers Automatic Presenter Systems for screws, bolts, nuts, and pins. These systems are typically used for fasteners that cannot be blown to automatic screwfeeding equipment due to the fastener design, or for locations that do not have room for automatic feed screwdrivers. These systems present an isolated fastener at a fixed pickup point so that the driving or pick and place system can access the individual fastener. Productivity increases significantly by operators not fumbling with fasteners and reduces worker’s injuries or claims. These systems promote fast and easy assembly with a more ergonomical range of motion.

DTI - Screw Dispensers

Design Tool Inc. offers Automatic Feed Screw Dispensing systems for nuts, bolts, screws, and pins. These systems are design to feed a predetermined number of fasteners into a collection bin assembly. The exact count allows fastener accountability to eliminate waste and prevent extra fasteners from being accidently dropped into assemblies. These systems also prevent extra fasteners from becoming a safety hazard to the end user in applications such as air bag assemblies in automobiles. The systems use a vibratory bowl feeder and patented Design Tool Inc. single exit feed mechanism to feed, count, and deliver the fasteners to the collection bin assembly. These systems utilize programmable logic controllers to operate the feed and blow mechanism.

Other Products

DTI - Automatic Brass Head Nailing Systems

The Design Tool Inc. Automatic Brass Head Nailing Systems are designed to drive brass head decorative nails in furniture applications. The design of the nail gun barrel assembly allows the nails to be driven into a variety of fabrics and frame materials without marring the nail head. The barrel assembly design also centers the nails so that they are driven straight each time, and accommodates driving the nail from any direction rotationally for ease of use. The barrel design also allows the nails to be drive head to head. This feature makes it easier for the operator to maintain nail alignment on the application. The nail guns are extremely fast, and are available for almost all brass head nail sizes.