Diemme Soil Washing S.r.l. products

Filter Presses

Diemme - Mobile Sludge Filtration System

DIEMME SOIL WASHING manufactures complete mobile filtration systems on trailers, equipped with a cake discharge system, completely independent for autonomous use in the mechanical dewatering of sludge or in combination with the water treatment and sludge conditioning line on containers like structures.

Diemme - Upper Beam Filter Press

The Filter Press UBF model is characterized by the level of total automation together with a high beam frame pull-in closing system made by four jacks, it is available up to the plate size 2500×2500 mm.

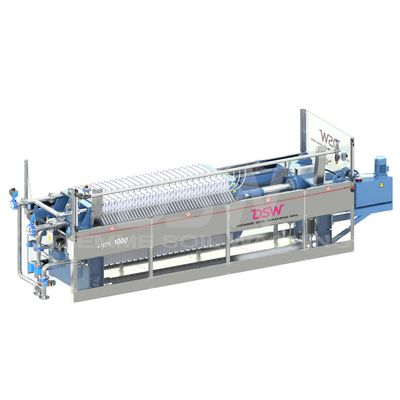

Diemme - Simultaneous Opening Filter Press

The FPS model is characterized by the level of total automation. Also called UNMANNED FILTER because it does not require personnel, even during the cake unloading phase. It is characterized by extreme versatility and speed in the unloading phases thanks to the simultaneous opening of the entire plate pack. Depending on the length of the filter, it is also possible to have sequential openings of multiple plates packs.

Diemme - Automatic Filter Press

The APS model is available from the plate size 630×630 mm and is mainly characterized by automation in the opening and closing phases of the Filter Press with automatic hydraulic power unit. The plate movement sequence is automatic and managed by an inverter with the possibility of adjusting the plate shifting times. APS is characterized by a frame with lateral beams and a push to close central hydraulic cylinder.

Diemme - Manual Filter Press

DIEMME SOIL WASHING with a tradition of group and highly qualified personnel in the field of solid-liquid separation almost secular, produces Filter Presses for various industrial sectors, with customized solutions for the specific needs of its customers.

Plant - Soil Washing and Sediment Washing Plants

Diemme - Soil Washing and Sediment Washing Stationary Plants

A fixed industrial plant for soil or sediment treatment is normally built for the remediation of a very large area that contains a high quantity of contaminated material. It can also be built as an integral part of a multipurpose waste treatment and recovery centre that can be used for an extremely wide range of EWC codes. The work synergies that are created, make the soil washing process a versatile and efficient technological process system, which can pre-treat a wide variety of contaminated matrices by preparing them for other processes and it can, in turn, be fed with processed residues and waste from other technological lines. A multipurpose centre becomes the main actor of an organic and integrated treatment and recovery system for a vast geographical area by accepting waste from different sites and with very different pollutants.

Diemme - Soil Washing and Sediment Washing Mobile Plants

The need to treat more and more potentially contaminated soils and sediments, in remote areas or distant from fixed plants, has created the need for completely mobile, extremely flexible systems, with reduced mobilization and de-mobilization times. DIEMME SOIL WASHING has responded to this market need by designing and building a new series of multifunctional systems that are quick to install and with treatment capacities equivalent to fixed systems.

Diemme - Road Sweeping, Gully Waste and Sand from Sewage Treatment Plants

DIEMME SOIL WASHING has developed, with proprietary technologies, a process of treatment and recovery of waste from street sweeping, gully waste and sands from sewage treatment plants (EWC 200303, 200304, 200306) which allows to greatly reduce the environmental impact generated by these types of waste by recovering most of the inert fraction minimizing what is left over for disposal.

Plant - Water Treatment Plants

Diemme - Water Treatment and Clarification Plants

DIEMME SOIL WASHING designs and manufactures complete water treatment plants including chemical conditioning, clarification, sedimentation, sludge and clear water storage section.

Diemme - Water Filtration Skid Plant

DIEMME SOIL WASHING has developed water filtration systems for the treatment of contaminated waste from its plants, which it also offers as autonomous unit for the finishing of plant and process water.