Dipesh Engineering Works products

Hydrogenators

At Dipesh Engineering Works, we specialize in designing and supplying coded Hydrogenators with highly efficient impellers and overall agitators for gas liquid reactions in aggressive services.

Autoclaves

We manufacture industrial-grade Autoclaves with Quick Opening Doors for Cement, Graphite, Rubber, Wood, Glass and other industries that can endure 350 deg.C temperature and 30 bar pressure. We also offer world-class Aerospace grade composite Autoclaves under Public-Private Partnership with CSIR-NAL (National Aerospace Laboratories, Bangalore).

Reactors & Agitators

140 KL Total Capacity SS316 Limpeted Reactor

With CS Skirt. 3 Nos. Pitched Blade Turbine. One Curved Turbine with Single Dry Mechanical Seal ,Internal Rigid Coupling. SS304 Lantern Stool. Inline Helical Bonfiglioli make Gear Box and Compton make FLP Motor with internal and external Pickling Passivation with Lug Supports.

15 KL Total Capacity SS316 Jacketed Reactor ( Gas – Induction Reactor )

With dual Internal Coil. 2 Nos. Gas –Induction. One Curved Turbine with Double Mechanical Seal with Force Lubrication, Internal Rigid Coupling. CS Lantern Stool. Inline Helical Bonfiglioli make Gear Box and Compton make FLP Motor with internal and external Pickling Passivation with Lug Supports.

67 KL Total Capacity SS316 Limpeted Reactor

2 Pitched Blades. One Ruston Turbine with Bottom Bush Arrangement Flow-Serve make single Dry Mechanical Seal, with Internal Rigid Couplin. SS304 Lantern Stool. Inline Helical Nord make Gear Box and Compton make FLP Motor with internal and external Polishing resting on Skirt Support.

50 KL Total Capacity SS316 Limpeted ( Neutralizer ) Reactor

Dual Internal Coil. 2 Nos. Pitched Blades. One Curved Blade Turbine with Bottom Bush Arrangement, Jacketed Stuffing Box, with Internal Rigid Coupling. CS Lantern Stool. Inline Helical Nord make Gear Box and Compton make FLP Motor with internal and external Polishing resting on Skirt Support.

Mixers, Dryers & Rotary Equipment

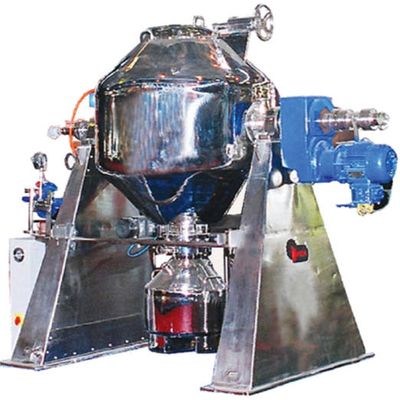

Rotocone Vaccum Dryer

C-GMP concept. Mechanical seal for inlet & outlet of hot media. Sizes available from 100 L to 20000 L. Vapour filter with high filter area & easily detachable function. Internal surface finish upto 600 grit mechanical polish having crevice free internals. Provision of sampling valve without vaccum break. Available in SS, Hastelloy & Teflon coated construction. Accessories such as cyclone separator, vaccum pump, condenser, heating & cooling system for solvent recovery can be tailored as per client’s requirement.

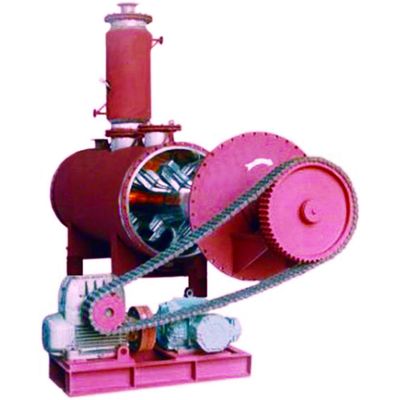

Rotary Vacuum Paddle Dryer

Energy Consumption is Low due to higher differential temperatures. Suitable for drying materials which are sensitive to heat, it can maintain low temperatures using high vacuum. Maximum Solvent Recovery is done.