Doing Holdings - Henan Jinrui Food Engineering Co., Ltd products

Henan Jinrui - Garri dewatering machine Cassava flour and gari dehydrator

When using garri dewatering machine, firstly we need pull put the cylinder and put fermented garri in, then garri is pressed by hydraulic pumping station. The pressed extra water flows out from the press barrel hole and flows to the designated place. The working pressure and the pressing time of the garri dewatering machine can be set freely: including the total time of single press and the reciprocating frequency of short-distance press. Manual automatic convertible: Generally use manual mode first, switch to automatic when going down to a certain position, after the automatic pressing time is completed, the pressure plate is automatically reset. http://www.cassavaprocessing.com WhatsApp/Phone:+86 135 2661 5783 Email:market@doinggroup.comHenan Jinrui - Cassava garri dewatering machine Hydraulic press

Hydraulic press is a widely used garri dewatering machine whose main function is to dewater the extra water from garri. It uses the system of hydraulic and reliable electronic controlling to directly squeeze the water of material and discharge out of charging barrel. In the process of garri and cassava flour making , the machine is going to remove component moisture. In order to ensure that the good quality of finished product, the garri dewatering machine is necessary and indispensable. https://www.cassavaprocessingplant.com WhatsApp/Phone:+86 135 2661 5783 Email:market@doinggroup.comCassava Starch Processing Machine

Paddle Washer

Function: To further wash cassava. After cleaning, the paddle washer is adopted to remove mud, peel and other impurities from cassava tubers, and water is required. This cassava starch processing machine adopts countercurrent washing principle, by the effect of paddle rotating, cassava tubers flows in the converse direction against water, which makes washing completely and eliminate sand and mud effectively.

Cutting Machine

Function: To cut cassava tubers into small pieces. Cassava tubers usually large and irregular in shape. Therefore, in the production process of the cassava starch processing machine, the cassava tubers should be cut into small pieces with the cutting machine, and then for further crushing, which can not only reduce the pressure of the rasper, but also is conducive to the full crushing of cassava.

Henan Jinrui - Cassava starch processing line cassava tapioca starch extraction machinery centrifuge sieve

Cassava starch extraction line-sieving step: To separate fibers from starch slurry. The crushed starch slurry need to be sieved in this step to separate fibers from starch slurry. The large fibers are removed by using centrifugal sieve and fine fibers are further removed by fine fiber sieve. These two cassava starch processing machines are mainly to achieve the purpose of separating and purifying of the starch. Multiple separation and countercurrent washing processes are commonly employed, and after separation, the fiber impurities content of the starch slurry is less than 0.05%. http://www.cassavaprocessing.com WhatsApp/Phone:+86 135 2661 5783 Email:market@doinggroup.comSweet Potato Starch Machine

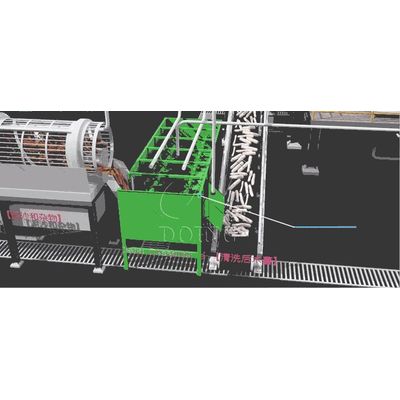

Rotary Washing Machine

The sweet potatoes go into the rotary washing machine by the transportation of the belt conveyor. The reason that using the rotary washing machine in the sweet potato starch machine to clean the sweet potato is the shape of the sweet potatoes. It’s shape is always round and can’t be pushed by the pulp in the paddle washing machine. However, the design of the rotary washing machine is very good in line with the characteristics of sweet potatoes.

Centrifuge Sieve Machine

The starch pulp is separated from sweet potato residues to avoid oxidation browning during starch extraction, which is convenient for the production of white and fine starch. The centrifuge machine can separate the fibers from starch slurry is the key to extract the starch in sweet potato starch machine. The sieve basket is made of titanium plate, with laser punching processing.