- Home

- Companies

- Dolphin Centrifuge

- Products

Dolphin Centrifuge products

Laval Centrifuges

Dolphin - Centrifuge

The Alfa Laval MAB 103 Centrifuge is a solid-retaining (aka solid bowl; manual-clean), disc-stack centrifuge ideal for the continuous, three-phase separation of fuels, such as diesel, biodiesel, and turbine lube oil. With a 1 HP Motor, the MAB 103 centrifuge has a bowl RPM of 8,600 and can process 3 GPM of Diesel Fuel or 1 GPM of Turbine Lube Oil.

Dolphin - Centrifuge

The Alfa Laval MAB 104 Centrifuge is a solid-retaining (aka solid bowl; manual-clean), disc-stack centrifuge ideal for the continuous, three-phase separation of fuels, such as diesel, biodiesel, and turbine lube oil. With a 2 HP Motor, the MAB 104 centrifuge has a bowl RPM of 7,500 and can process 6 GPM of Diesel Fuel or 1 GPM of Turbine Lube Oil.

Dolphin - Decanter | High Performance Centrifuge

The Alfa Laval G2-40 Decanter Centrifuge is a horizontal de-sludging centrifuge built for the two-phase separation of wastewater, crude oil tank bottoms, municipal sludge-thickening, industrial sludge dewatering, paint sludge handling, etc. With a 25 HP Motor, the G2-40 decanter has a bowl RPM of 4,000 and can process 160 GPM of water with light sludge.

Dolphin - Two-Phase Decanter Centrifuge with Inert Gas Purging

The Alfa Laval CHNX 418 Decanter Centrifuge is a horizontal de-sludging centrifuge built for the two-phase separation of wastewater, crude oil tank bottoms, municipal sludge-thickening, industrial sludge dewatering, paint sludge handling, etc. This decanter has an inert gas purge system installed for nitrogen purging of the operating space. This purge includes the container vessel and inlet feed pipe housing. With a 20 HP Motor, the CHNX 418 decanter has a bowl RPM of 4,000 and can process 100 GPM of water with light sludge.

Other Centrifuge

Dolphin - Disc Stack Centrifuge

A disc stack centrifuge is a specifically designed industrial centrifuge with a stack of cone-shaped discs. The additional surface increases the settling area multi-fold and reduces the settling distance. Combined with the high g-force (7,000 Gs), these features make this centrifuge a highly efficient separation device for fine particles (0.5µm) and immiscible liquids.

Dolphin - Decanter Centrifuge Module for WVO Processing

A decanter centrifuge is an industrial centrifuge that continuously separates solids from liquids. The separation in the decanter occurs due to the high centrifugal force generated by its rotating bowl. Solid particles need a higher density than liquid for a decanter centrifuge to work. Given its separating abilities, the decanter finds a variety of applications in biotechnology separation, oil fields, wastewater treatment, the food industry, hemp processing.

Dolphin - Hazardous Area Explosion Proof Centrifuge

Industrial centrifuge applications need not be limited by the location or environment being unacceptable for standard machinery. Specially designed centrifuges are safe to install in potentially hazardous environments. In this article, we discuss various considerations and solutions for applying centrifuges in dangerous locations.

Dolphin - Stainless Steel Centrifuge for Chemical & Food Grade Applications

Stainless steel centrifuges are specially designed disc-stack centrifuges for separating corrosive chemicals and food products. A pass-through feature allows continuous processing through stainless-steel centrifuges. A high centrifugal force of over 7,000 g separates fine sediment down to 1 micron. The Alfa Laval stainless steel centrifuges are generally of the food-grade (sanitary) design configuration. This design means that all the fluid contact parts are made of high-grade stainless steel (316L).

Dolphin - Industrial Centrifuge Systems for Waste Oil

An industrial centrifuge is a separation machine that uses centrifugal force to separate solids from liquids. A centrifuge exerts a centrifugal force that is thousands of times that of gravity. This force causes the immediate separation of solids from liquids. And, in the case of immiscible liquids with different densities, it separates the fluids as well. You can think of an industrial centrifuge as a scaled-up version of a lab centrifuge (test tube) except at a much bigger scale with a flow-through design. That means the separated solids and liquid(s) continuously exit the centrifuge.

Controls System

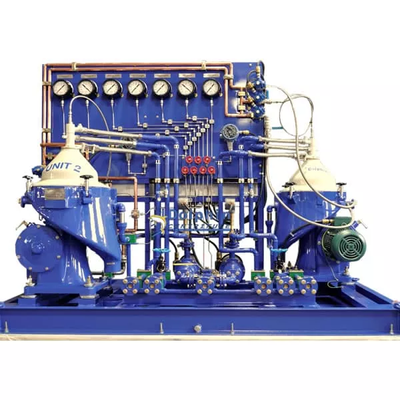

Dolphin - Fully Automatic Operation Industrial Centrifuge Controls System

Dolphin Centrifuge has developed its line of Industrial Centrifuge Control Systems. These controls are specific for Alfa Laval Disc Stack and Decanter Centrifuges. Our control panels incorporate the latest technologies available. Ease of use and built-in troubleshooting features are highlights of our control systems. They can be customized to provide unique functionalities and application-specific features. These include process data storage, DCS interface, and remote operator functionality.