Douglas Electrical Components products

Hermetic Connectors

Douglas Electrical Components - Model CircuitSeal - Hermetic Circuit Assemblies

CircuitSeal is the process of hermetically sealing and encapsulating connectors and electronic circuits within a low-outgassing, chemically inert hermetic epoxy. By encapsulating the circuit board, connector, or flex circuit, customers have increased design flexibility to design a small, lightweight electronic package. CircuitSeal can integrate a variety of circuit board and electrical connection types including flex, rigid, hybrid and flat flex cable (FFC). Circuit board encapsulation protects against corrosion and electrical shorts caused by water vapor and condensation or creates a hermetic barrier between the circuit and housing assembly or enclosure.

Douglas Electrical Components - Model PFW - Backpotted Connector Assembly

PFW (plug) and RFW (receptacle) series sealed connectors offer a combination of mechanical and electrical flexibility to design a plug-and-play electrical connection that is hermetic and moisture-tight. Douglas Electrical will start with the connector type required for the application; options include circular MIL-spec and industrial connectors, push-pull connectors, high-voltage connectors, and fiber optic connectors. The connector can be mechanically integrated into the flange or hardware of choice for flange mounting, bulkhead mounting, or threaded options for integration in whatever form is required. By integrating the flange or housing into the connector assembly, customers can reduce potential leak paths and save on hardware adaptations. The mechanical interface is available in a variety of materials based on customer and application needs and can be specified for vacuum or pressure applications. Material certs are available upon request.

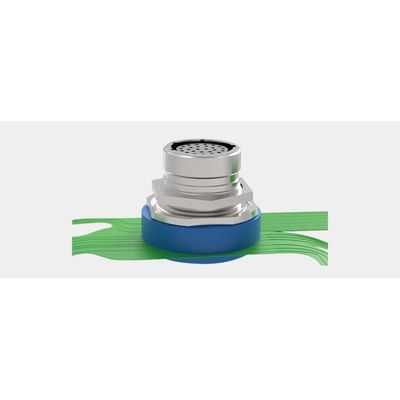

Douglas Electrical Components - Model BPC Series - Hermetic Backpotted Connector

Douglas Electrical Components offers hermetic, moisture-tight connector solutions through our BPC backpotted connector series. Standard commercial off-the-shelf (COTS) connectors can be converted to a hermetic design by backpotting the connector using our proprietary process. Douglas Electrical can also hermetically seal obsolete hermetic connector options for customers to maintain backwards compatibility, redesign a legacy product, or source a replacement. Our hermetically sealed connectors protect power and signal connections from environmental conditions. The enclosure contents and electronics are protected against liquids and gases from water vapor to fuels.

Wire & Cable Feedthroughs

Douglas Electrical Components - Model JacketSeal Series - Sealed Wire & Cable Feedthroughs

JacketSeal sealed electrical feedthroughs provide a liquid/fluid/water-tight sealing solution where a true hermetic seal is not required. Sealed electrical feedthroughs are commonly used applications that require mild water blocking or sealing to IP-67, IP-68, NEMA, and explosion-proof standards. JacketSeal™ technology can be integrated into various sensor, instrumentation, and transmitter designs, simplifying the manufacturing process while reducing exposure of electronics to environmental conditions. As the cable or wire passes through the mechanical interface, the epoxy bonds to the conductors using a proprietary process to protect against liquid and gas penetration.

Douglas Electrical Components - Cable Harnesses

Douglas Electrical’s engineering team designs custom cable harness assemblies to industrial, hazardous area, and military standards, making them suitable for a wide range of applications and industries. Manufactured by IPC-620 certified technicians in our New Jersey facilities, our cable harnesses are tested to the highest quality and compliance standards. Each crimp, solder joint, and connection are handled with care. Harnesses and cable entry seals undergo 100% electrical testing before leaving our facility.

Feedthroughs by Housing Type

Douglas Electrical Components - Model CF Series - Vacuum Feedthroughs

Douglas Electrical Components manufactures hermetic electrical feedthroughs utilizing a CF (Conflat*) flange to create convenient mounting and installation. Our vacuum rated CF feedthroughs are available in various electrical connections including connectors, wires, cables, and optical fibers. Our epoxy technology permits us to not only create high density feedthroughs, but also combine multiple interfaces into the same feedthrough flange, reducing overall feedthrough cost and saving space. This can be as simple as integral thermocouple wire to connectorized harnesses with integral shielding, strain relief, and sleeves.